Popular Woodworking 2007-12 № 166, страница 12

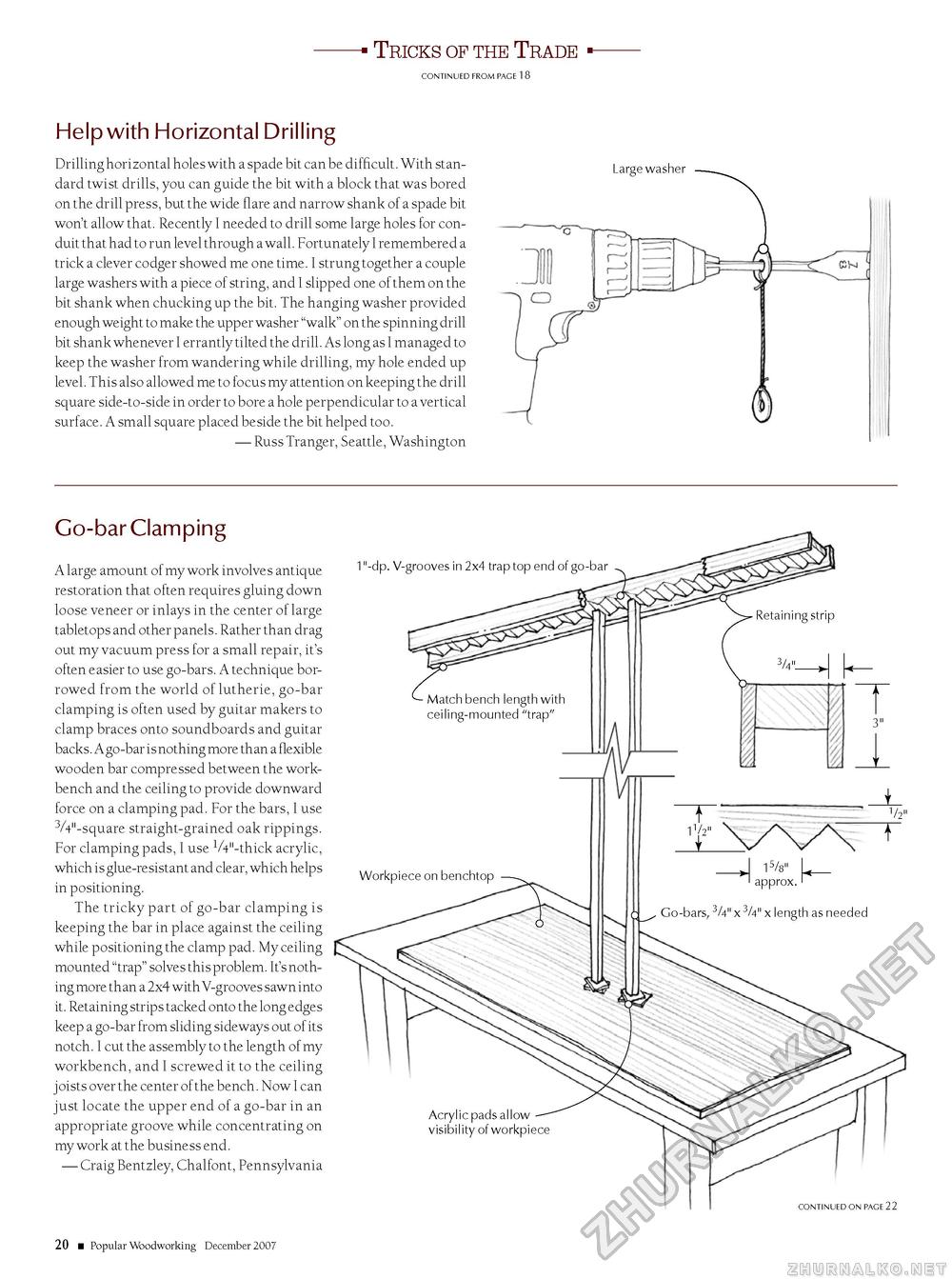

Tricks of the Trade CONTINUED FROM PAGE 1 8 Help with Horizontal Drilling Drilling horizontal holes with a spade bit can be difficult. With standard twist drills, you can guide the bit with a block that was bored on the drill press, but the wide flare and narrow shank of a spade bit won't allow that. Recently I needed to drill some large holes for conduit that had to run level through a wall. Fortunately I remembered a trick a clever codger showed me one time. I strung together a couple large washers with a piece of string, and I slipped one of them on the bit shank when chucking up the bit. The hanging washer provided enough weight to make the upper washer "walk" on the spinning drill bit shank whenever I errantly tilted the drill. As long as I managed to keep the washer from wandering while drilling, my hole ended up level. This also allowed me to focus my attention on keeping the drill square side-to-side in order to bore a hole perpendicular to a vertical surface. A small square placed beside the bit helped too. — Russ Tranger, Seattle, Washington Go-bar Clamping A large amount oi my work involves antique restoration that often requires gluing down loose veneer or inlays in the center oi large tablet ops and other panels. Rather than drag out my vacuum press tor a small repair, it's often easier to use go-bars. A technique borrowed from the world of lutherie, go-bar clamping is often used by guitar makers to clamp braces onto soundboards and guitar backs. A go-bar isnothing more than a flexible wooden bar compressed between the workbench and the ceiling to provide downward force on a clamping pad. For the bars, I use W'-square straight-grained oak rippings. For clamping pads, I use V-t'-thick acrylic, which is glue-resistant and clear, which helps in positioning. The tricky part of go-bar clamping is keeping the bar in place against the ceiling while positioning the clamp pad. My ceiling mounted "trap" solves this problem. It's nothing more than a 2x4 with V-grooves sawn into it. Retaining strips tacked onto the long edges keep a go-bar trom sliding sideways out oi its notch. I cut the assembly to the length oi my workbench, and I screwed it to the ceiling joists over the center oi the bench. Now I can just locate the upper end oi a go-bar in an appropriate groove while concentrating on my work at the business end. — Craig Bentzley, Challont, Pennsylvania Acrylic pads allow visibility of workpiece CONTINUED ON PAGE 22 20 ■ Popular Woodworking December 2007 |