Popular Woodworking 2008-04 № 168, страница 69

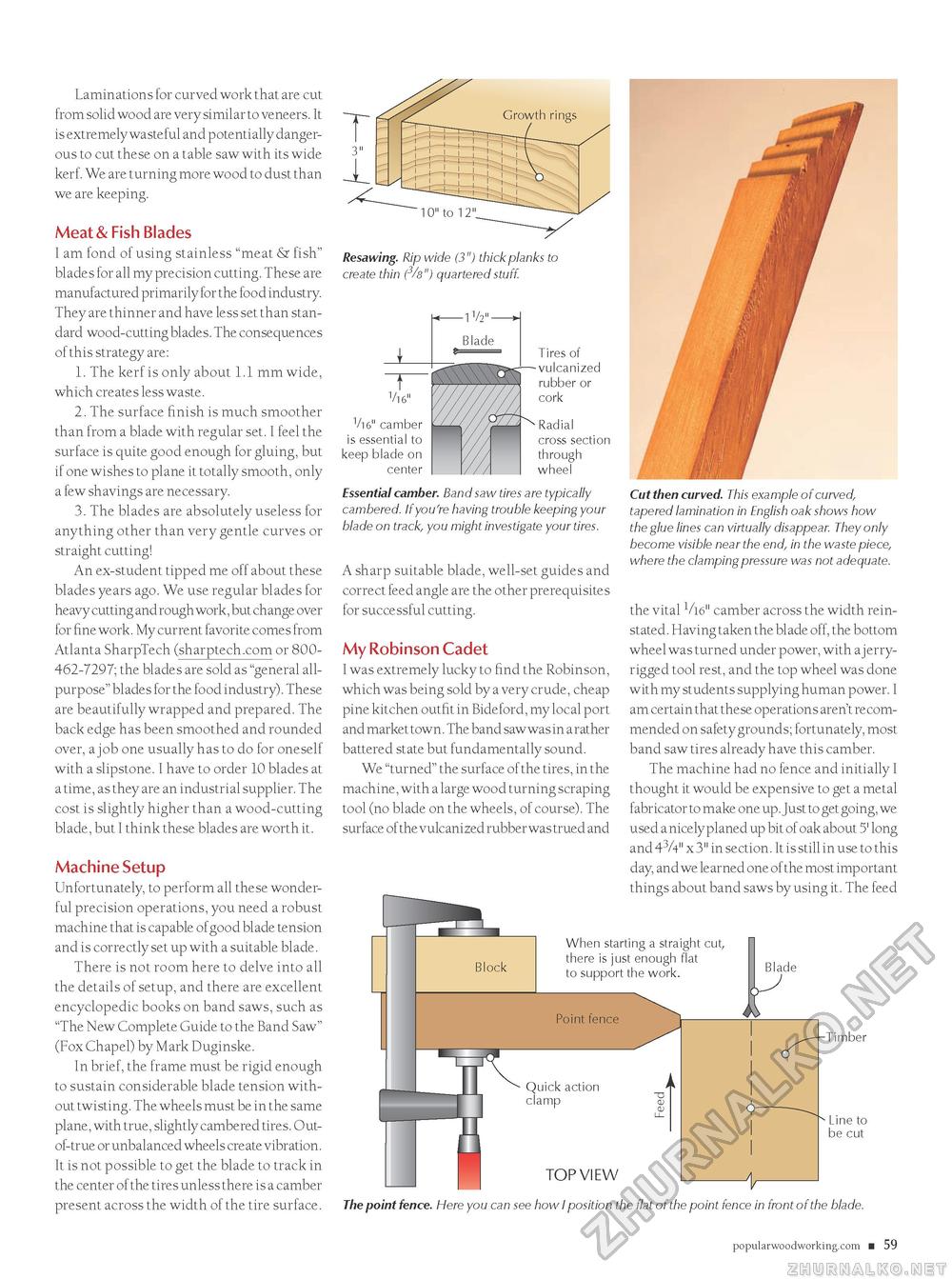

Laminations for curved work that are cut from solid wood are very similar to veneers. It is extremely wasteful and potentially dangerous to cut these on a table saw with its wide kerf. We are turning more wood to dust than we are keeping. Meat & Fish Blades I am fond of using stainless "meat & fish" blades for all my precision cutting. These are manufactured primarily for the food industry. They are thinner and have less set than standard wood-cutting blades. The consequences of this strategy are: 1. The kerf is only about 1.1 mm wide, which creates less waste. 2. The surface finish is much smoother than from a blade with regular set. I feel the surface is quite good enough for gluing, but if one wishes to plane it totally smooth, only a few shavings are necessary. 3. The blades are absolutely useless for anything other than very gentle curves or straight cutting! An ex-student tipped me off about these blades years ago. We use regular blades for heavy cutting and rough work, but change over for fine work. My current favorite comes from Atlanta SharpTech (sharptech.com or 800462-7297; the blades are sold as "general all-purpose" blades for the food industry). These are beautifully wrapped and prepared. The back edge has been smoothed and rounded over, a job one usually has to do for oneself with a slipstone. I have to order 10 blades at a time, as they are an industrial supplier. The cost is slightly higher than a wood-cutting blade, but I think these blades are worth it. Machine Setup Unfortunately, to perform all these wonderful precision operations, you need a robust machine that is capable of good blade tension and is correctly set up with a suitable blade. There is not room here to delve into all the details of setup, and there are excellent encyclopedic books on band saws, such as "The New Complete Guide to the Band Saw" (Fox Chapel) by Mark Duginske. In brief, the frame must be rigid enough to sustain considerable blade tension without twisting. The wheels must be in the same plane, with true, slightly cambered tires. Out-of-true or unbalanced wheels create vibration. It is not possible to get the blade to track in the center of the tires unless there is a camber present across the width of the tire surface. Resawing. Rip wide (3") thick planks to create thin (3/s") quartered stuff. A. —i V211— Blade Vie" Vi6" camber is essential to keep blade on center Tires of —-vulcanized rubber or cork Radial cross section through wheel Essential camber. Band saw tires are typically cambered. If you're having trouble keeping your blade on track, you might investigate your tires. A sharp suitable blade, well-set guides and correct feed angle are the other prerequisites for successful cutting. My Robinson Cadet I was extremely lucky to find the Robinson, which was being sold by a very crude, cheap pine kitchen outfit in Bideford, my local port and market town. The band saw was in a rather battered state but fundamentally sound. We "turned" the surface of the tires, in the machine, with a large wood turning scraping tool (no blade on the wheels, of course). The surface of the vulcanized rubber was trued and Cut then curved. This example of curved, tapered lamination in English oak shows how the glue lines can virtually disappear. They only become visible near the end, in the waste piece, where the clamping pressure was not adequate. the vital 1/t6" camber across the width reinstated. Having taken the blade off, the bottom wheel was turned under power, with a jerry-rigged tool rest, and the top wheel was done with my students supplying human power. I am certain that these operations aren't recommended on safety grounds; fortunately, most band saw tires already have this camber. The machine had no fence and initially I thought it would be expensive to get a metal fabricator to make one up. Just to get going, we used a nicely planed up bit of oak about 5' long and 43A" x 3" in section. It is still in use to this day, and we learned one of the most important things about band saws by using it. The feed Block When starting a straight cut, there is just enough flat to support the work. Point fence fitQuick action clamp TOP ViEW Timber Line to be cut The point fence. Here you can see how I position the flat of the point fence in front of the blade. popularwoodworking.com ■ 59 CIRCLE #100 ON FREE INFORMATION CARD. |