Popular Woodworking 2008-06 № 169, страница 34

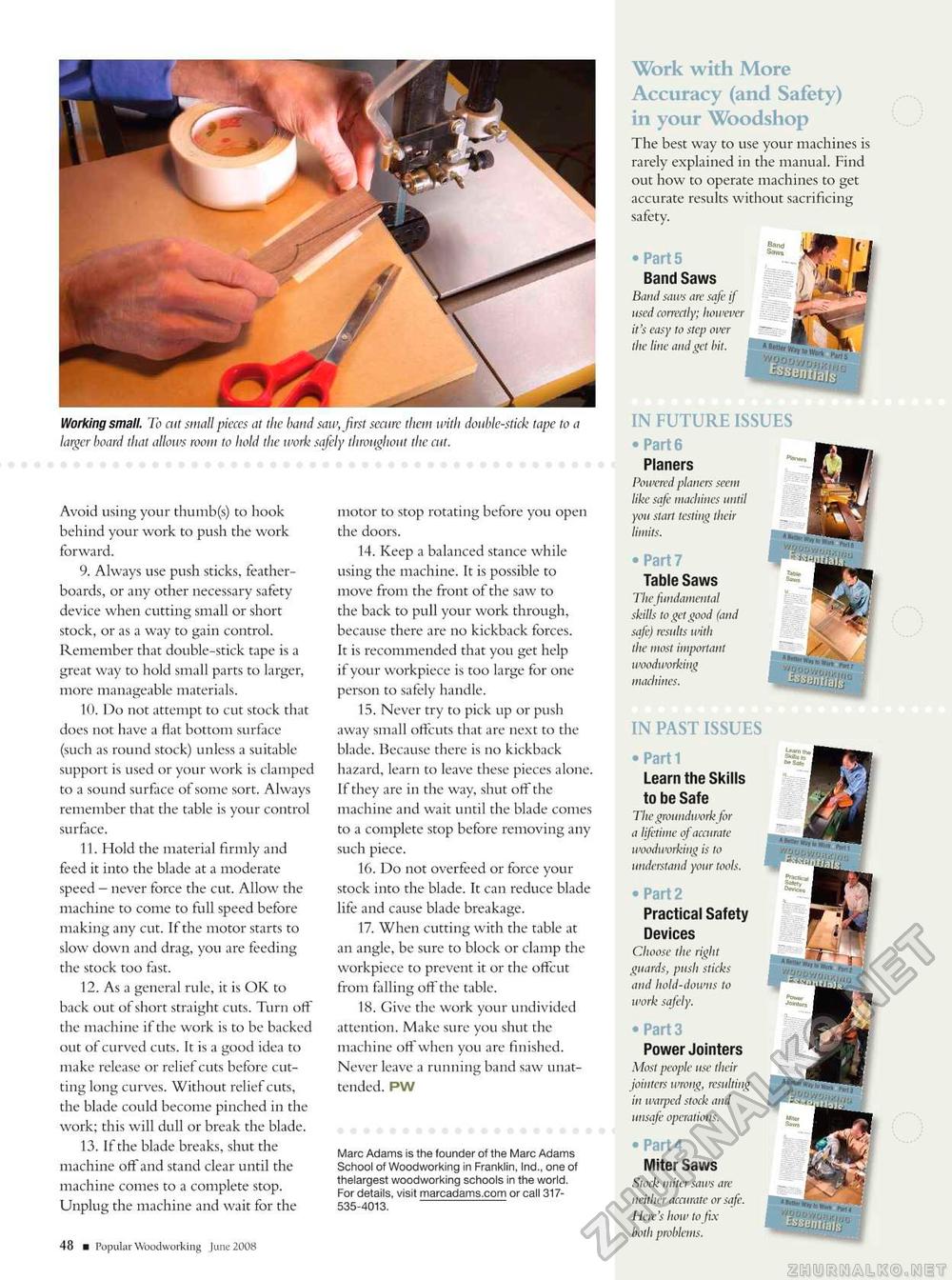

Working small. To ctil small pieces at the band saw, first secure them with double-stick tape tc larger board that allows room to hold the work safely throughout the ait. Avoid using your thumb(s) to hook behind your work to push the work forward. 9. Always use push sticks, feather-boards, or any other necessary safety device when cutting small or short stock, or as a way to gain control. Remember that double-stick tape is a great way to hold small parts to larger, more manageable materials. 10. Do not attempt to cut stock that does not have a flat bottom surface (such as round stock) unless a suitable support is used or your work is clamped to a sound surface of some sort. Always remember that the table is your control surface. 11. Hold the material firmly and feed it into the blade at a moderate speed - never force the cut. Allow the machine to come to full speed before making any cut. If the motor starts to slow down and drag, you are feeding the stock too fast. 12. As a general rule, it is OK to back out of short straight cuts. Turn off the machine if the work is to be backed out of curved cuts. It is a good idea to make release or relief cuts before cutting long curves. Without relief cuts, the blade could become pinched in the work; this will dull or break the blade. 13. If the blade breaks, shut the machine off and stand clear until the machine comes to a complete stop. Unplug the machine and wait for the 12 ■ Popular Woodworking June 2008 motor to stop rotating before you open the doors. 14. Keep a balanced stance while using the machine. It is possible to move from the front ofthe saw to the back to pull your work through, because there are no kickback forces. It is recommended that you get help if your workpiece is too large for one person to safely handle. 15. Never try to pick up or push away small offcuts that are next to the blade. Because there is no kickback hazard, learn to leave these pieces alone. If they are in the way, shut off the machine and wait until the blade comes to a complete stop before removing any such piece. 16. Do not overfeed or force your stock into the blade. It can reduce blade life and cause blade breakage. 17. When cutting with the table at an angle, be sure to block or clamp the workpiece to prevent it or the offcut from falling off the table. 18. Give the work your undivided attention. Make sure you shut the machine off when you are finished. Never leave a running band saw unattended. PW Marc Adams is the founder of the Marc Adams School of Woodworking in Franklin, Ind., one of thelargest woodworking schools in the world. For details, visit marcadams.com or call 317-535-4013. Work with More Accuracy (and Safety) in your Woodshop The best way to use your machines is rarely explained in the manual. Find out how to operate machines to get accurate results without sacrificing • Part 5 Band Saws Band saws are safe if used correctly; however it's easy to step ovei the line and get bit. IN FUTURE ISSUES • Part 6 Powered planers seem like safe machines until you start testing their • Part 7 Table Saws Thefundamental skills to get good (and safe) results with the most important woodworking machines. IN PAST ISSUES • Parti Learn the Skills to be Safe The groundwork for a lifetime of accurate woodworking is to understand your tools. • Part 2 Practical Safety Devices Choose the right guards, push sticks and hold-downs to work safely. • Part 3 Power Jointers Most people use their jointers wrong, resulting in warped stock and unsafe operations. |