Popular Woodworking 2008-10 № 171, страница 65

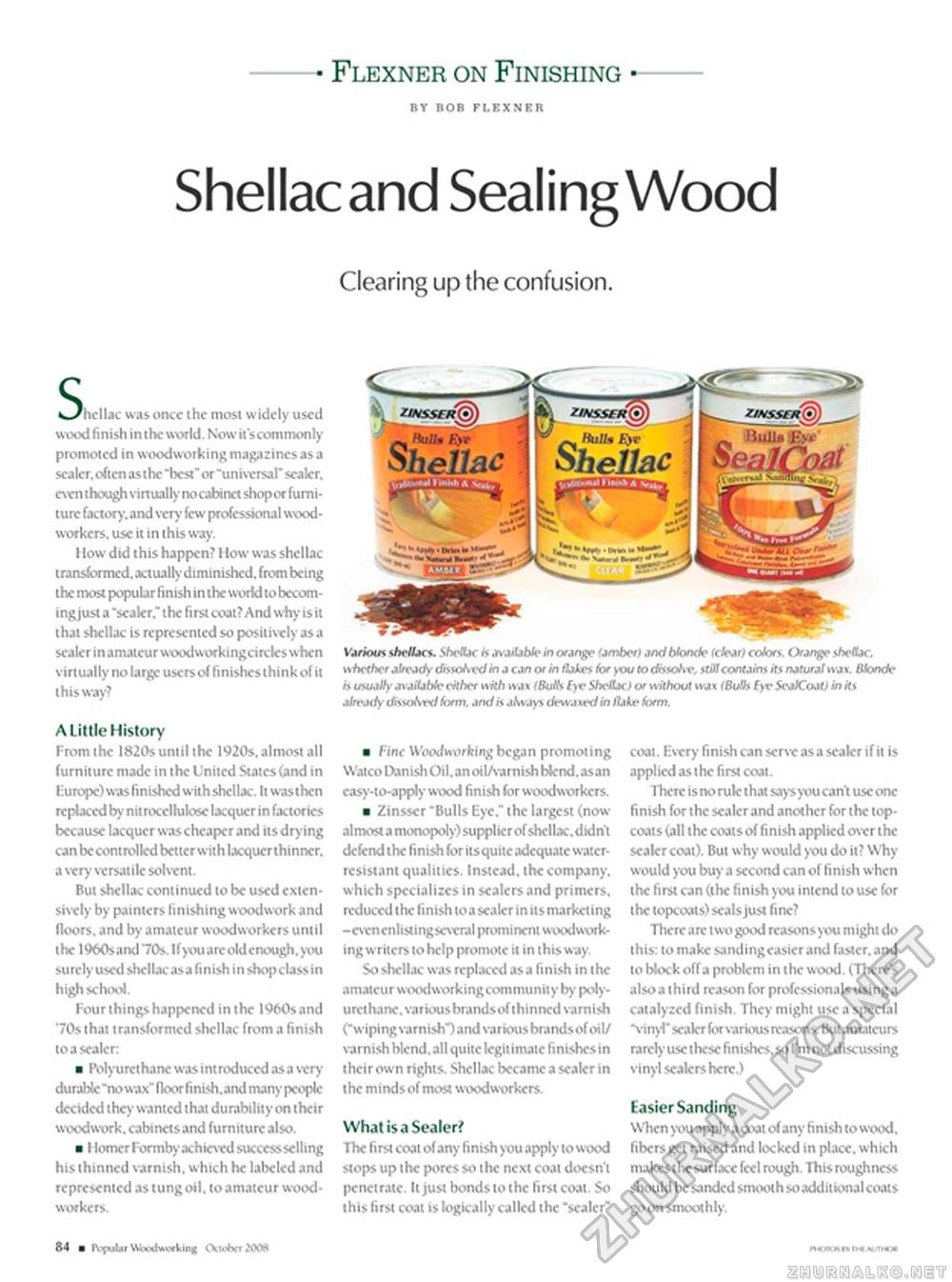

• Flexner on Finishing • BY BOB FI.KXNER Shellac and Sealing Wood Clearing up the confusion. Various shellacs. S hetlac rs available in orange 'amber) and blonde (clear) colors. Orange shellac, whriher already dissolved in a can or in flakes for you to dissohe, StM contains its natural wan. Blonde is usually availaltlr either with wax (BuHs [ye Shellac) or without wax (Bulk fyvSealCoat) inks already dfcsotved form, and is always drwaxedin flake form. s^^hellac was oncc ihc most widely used wood finish in the world. Now it's commonly promoted in woodworking magazines as a scaler, often asthc "bcsTor "universal" seakr. even though virtually nocabinct shop or furniture factory, and very few professional woodworkers. use it in this way. I low did this happen? How was shellac transformed, actually- diminished, from being the most popular finish in the wodd to bccom-ing just a "sealer." the fi rst coat? And why is it that shellac is represented so positively as a sealer in amateur woodworkingcircles when virtually no large users of finishes think of it this way? A Little History From the 1820s until the 1920s, almost all furniture made in the United States (and in Uuropc) was finished with shellac. It was then replaced by nitrocellulose lacquer in factories because lacquer was cheaper and its drying can be controlled better with lacqucrthinncr. a very versatile solvent. But shellac continued to be used extensively by painters finishing woodwork and floors, and by amateur woodworkers until the 1960sand 70s. Ifyou are oldenough. you surely used shellacasa finish in shopclassin high school. Four things happened in the 1960s and '70s that transformed shellac from a finish to a sealer ■ Polyurcthanc was introduced asa very-durable "no wax" floor finish.and many people decided they wanted that durability-on their woodwork, cabinets and furniture also. ■ I loner Formby achiev ed successselling his thinned varnish, which he labeled and represented as tungoil. to amateur woodworkers. ■ fine Woodworking began promoting Watco Danish Oil.an oilAarnish blend, asan casy-to-apply wood finish for woodworkers. ■ Zinsser "Bulls Eye." the largest (now almost a monopoly) supplier of shcllac. didn't defend the finish for itsquitc adequate water-resistant qualities. Instead, the company, which specializes in sealers and primers, reduced the finish to a sealer in its market ing -cvencnlisttngscvcral prominent woodworking writers to help promote it in this way So shcllac was replaced as a finish in the amateur woodworking community by poly-urct banc, various brands of thinned varnish ("wiping varnish") and various brands of oil/ varnish blend, all quite legitimate finishes in their own rights. Shcllac became a sealer in the minds of most woodworkers. What is a Sealer? The first coal of any finish you apply to wood stops up the pores so the next coat doesn't penetrate. Il just bonds to the first coat. So this first coat is logically called the "sealer" coat. Every finish can serve asa seakr if it is applied as the first coal. There isno ruk that says you cant use one finish for the sealer and another for the topcoats (all the coats of finish applied over the seakr coat). But why would you do it? Why would you buy a second can of finish when the first can (the finish you intend louse for the topcoats) seals just fine? There arc two good reasons you might do this: to make sanding easier and faster, and to block off a problem in the wood. (There's also a third reason for professionals using a catalyzed finish. They might use a special "vinyl" seakr for various reasons. But amateurs rarely use these finishes, so I'm not discussing vinyl seakrs here.) Easier Sanding When you apply a coal of any finish to wood, fibers gel raised and locked in place, which makesthe surface feel rough. This roughness should be sanded smooth so additional coats go on smoothly. 84 ■ IVpuUr Woodworking CVlohcr 200A |