Popular Woodworking 2008-10 № 171, страница 66

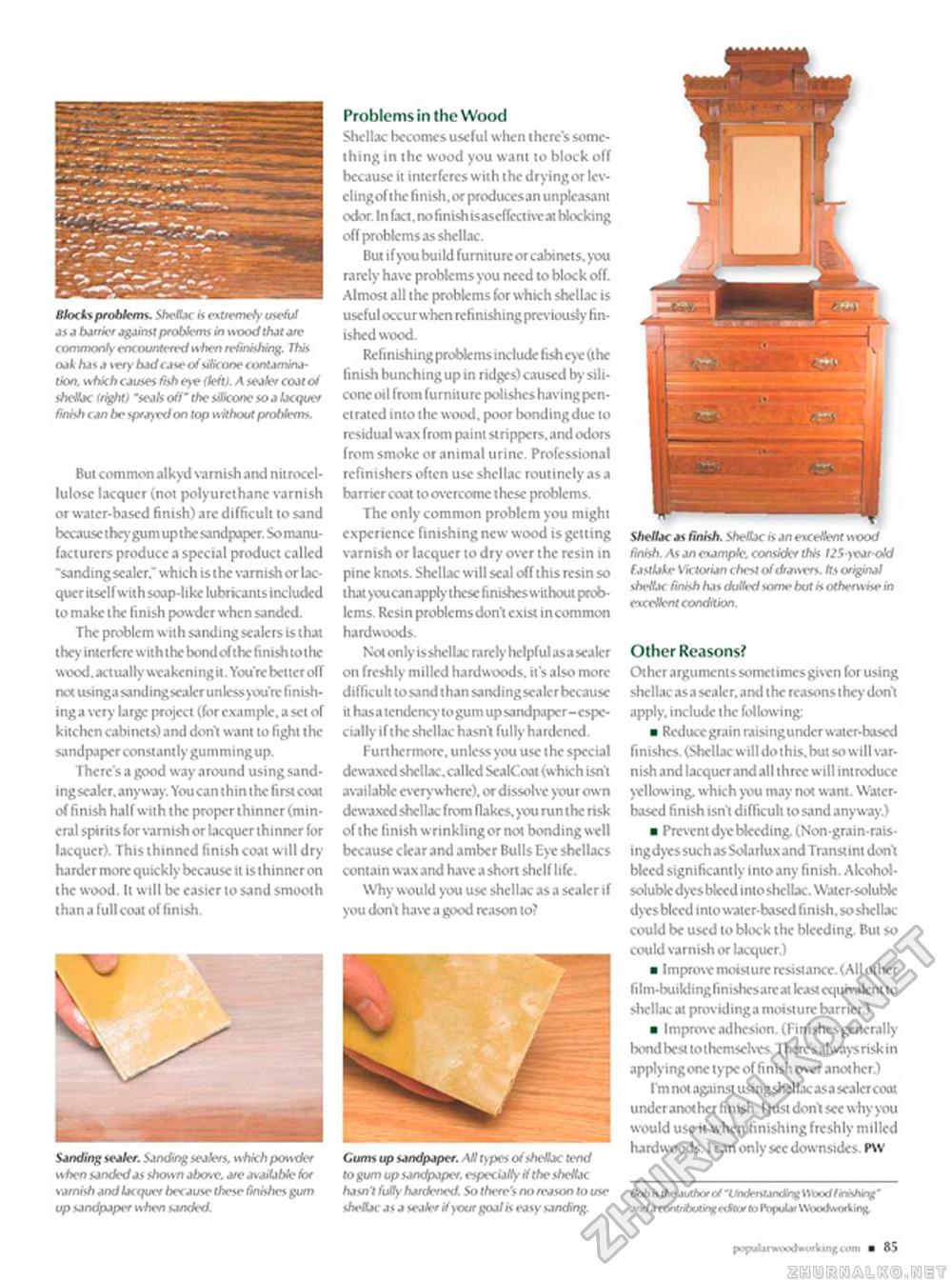

ft Blocks problems. ShtBac b extremely useful as a barrier against problems in wood that are conmxxity enc oonteted when refinishing. This oak has a \vry bad<aseof sitkone contamination. which causes fish eye (left). A sealer coat of shellac (right) 'seals off the silicone so a lacquer finish can be sprayed on top without problems. But common alkyd varnish and nitrocellulose lacquer (not polyurcthanc varnish or water-based finish) arc difficult to sand because they gum upthc sandpaper. So manufacturers produce a special product called 'sanding sealer." which is the varnish or lacquer itself with soap-like lubricants included to make the finish powder when sanded. The problem with sanding sealers is that they interfere with the bond ofthc finish to the wood, actually weakening it. You're better off not usingasandingsealer unless you're finishing a very large project (for example, a set of kitchen cabinets) and dont want to fight the sandpaper constantly gumming up. There's a good way around using sand-ingseakr. anyway. You can thin the first coat of finish half with the proper thinner (mineral spirits for varnish or lacquer thinner for lacquer). This thinned finish coat will dry-harder more quickly because it is thinner on the wood. Il will be easier to sand smooth than a full coal of finish. Problems in the Wood Shellac bccomcs useful when there's something in the wood you want to block off because it interferes with the drying or leveling of the finish, or produccsan unpleasant odor. In fact. nofinish isaseffect iveat blocking off problems as shellac. But if you build furniture or cabinets, you rarely have problems you need to block off. Almost all the problems for which shellac is useful occur when refinishing previously finished wood. Refinishing problems include fish eye (the finish bunching up in ridges) caused by silicone oil from furniture polisheshavingpen-ct rated into the wood, poor bonding due to residual wax from paint strippers, and odors from smoke or animal urine. Professional rcftnishcrs often use shellac routinely as a barrier coat to overcome t hese problems. The only common problem you might experience finishing new wood is getting varnish or lacquer to dry over the resin in pine knots. Shellac will seal off this resin so thai you can apply these finishcswithoui problems. Resin problcmsdon't exist incommon hardwoods. Not only isshcllac rarely helpful asa scaler on freshly milled hardwoods, it's also more difficult tosand than sanding sealer because il has a tendency to gum up sandpapcr-cspc-cially if the shellac hasnt fully hardened. Furthermore, unless you use the special dcwaxcdshcllac.callcd ScalCoat (which isn't available everywhere), or dissolve your own dewaxed shellac from flakes, you run the risk of the finish wrinkling or not bonding well because clear and amber Bulls Eye shellacs contain wax and have a short shelf life. Why would you use shellac as a sealer if you dont have a good reason to? Sanding sealer. Sanding sealers, whkh possder when sanded as shown above, are available for varnish and lacquer because these finishes gum up sandpaper when sanded. Cunts up sandpaper. AN types of shellac lend to gum up sandpaper, especially If the shellac hasn't fuBy hardened. So there's no reason to use shellac as a Stakf if your goal is easy sanding. Shellac as finish. Shellac is an excellent wood finish. As an example, consider this USyearold fast lake Victorian chest of drawers. Its original shellac finish has duNed some but is otherwise in excellent condition. Other Reasons? Other arguments sometimes given for using shellac asa sealer, and ihe reasons they don't apply, include the following: ■ Reduce grain raisingundcr water-based finishes. (Shellac will do this, but so will varnish and lacquerand all three will introduce yellowing, which you may not want. Water-based finish isn't difficult to sand anyway.) ■ Prevent dye bleeding (Non-grain-rais-ingdyes such as Solariux and Transtint dont bleed significantly into any finish. Alcohol-soluble dyvs bleed into shellac. Water-soluble dyesbleed into water-based finish, so shellac-could be used to block the bleeding. Bui so could varnish or lacquer.) ■ Improve moisture resistance. (All other film-building finishesare at least equivalent to shellac at providing a moisture barrier.) ■ Improve adhesion. (Finishes generally bond best to themselves. Tbcre'salways risk in applying one typeoffinish over another.) I'm not against usingshcllacasasealcrcoai under another finish. I just dont sec why you would use it when finishing freshly milled hardwoods. 1 can only sec downsides. PW Bob is the juthor ot 'Undemanding Wxx/1mcJvng' and J < wXritxMrx rrtft* to ftyxjlji Wuorfwoffcinn pofx>ljri»x<ihmiliii>f:vom ■ 85 |