Popular Woodworking 2008-11 № 172, страница 7

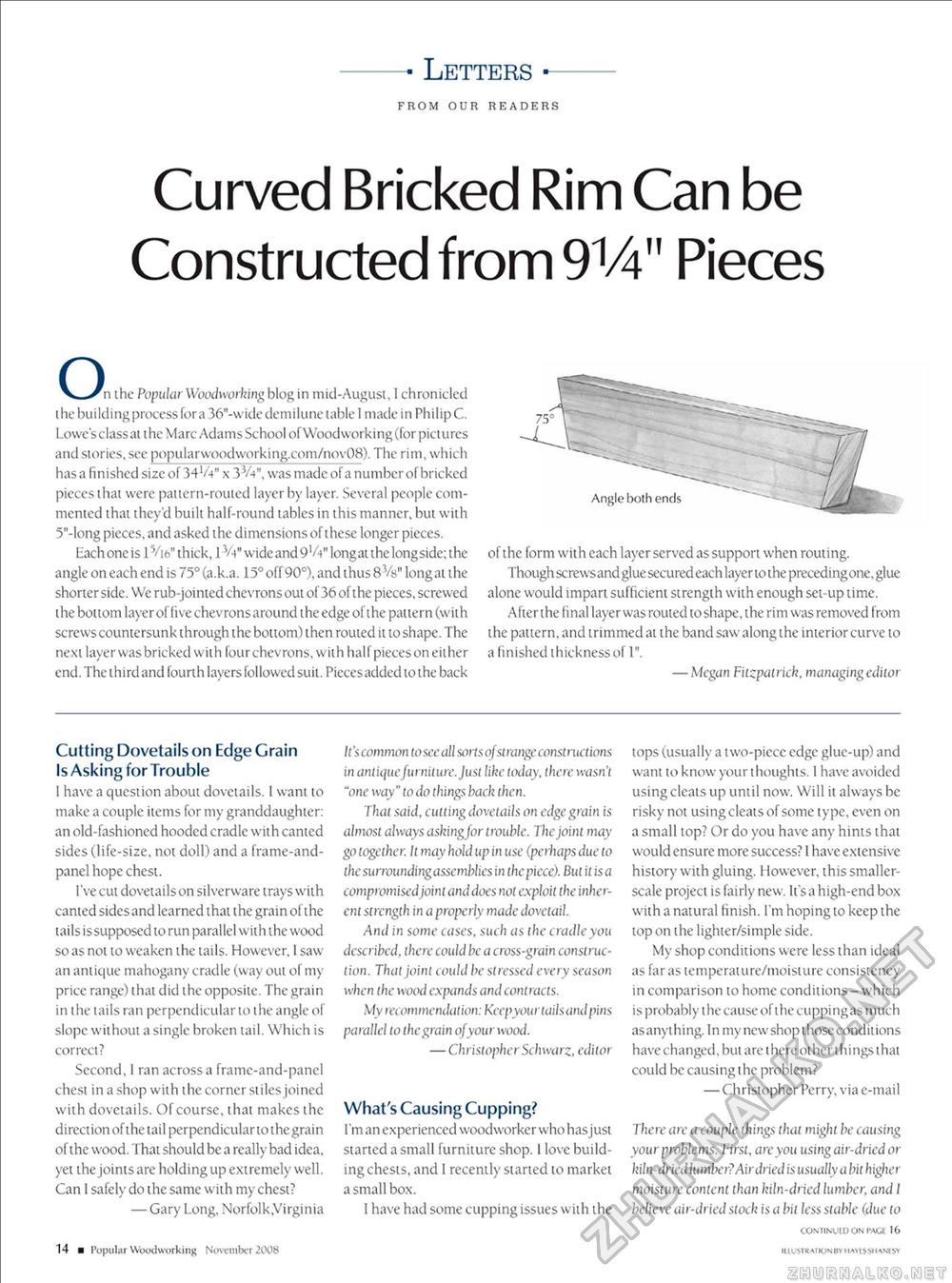

■ Letters • FROM OUR READERS Curved Bricked Rim Can be Constructed from 914" Pieces O the Popular Woodworking blog in mid-August, 1 chronicled the building process for a 36"-wide demilune table 1 made in Philip C. Lowe's class at i he Marc Adams School of Woodworking (for pict urcs and stories, see popularwoodworking.com/nov08). The rim, which has a finished size of 34VV' x 35/4", was made of a number of bricked pieces that were pattern-routed layer by layer. Several people commented that they'd built half-round tables in this manner, but with 5"-long pieces, and asked the dimensions of these longer pieces. Lachone is 15/V thick, 1 V-i" wide and 9'A" long at the longside: the angle on each end is 75° (a.k.a. 15° off 90°), and thus 8 V»" long at the shorter side. We rub-jointed chevrons out of 36 of the pieces, screwed the bottom layer offive chevrons around the edge of the pattern (with screws countersunk through the bottom) then routed it to shape. The next layer was bricked with four chevrons, with half pieceson either end. The third and fourth layers followed suit. Pieces added to the back of the form with each layer served as support when routing. Though screwsand glue secured each layer to the preceding one, glue alone would impart sufficient strength with enough set-up time. A I ter the final layer was routed to shape, the rim was removed from the pattern, and trimmed at the band saw along the interior curve to a finished thickness of 1". — Megan Fitzpatrick, managing editor Cutting Dovetails on Edge Grain Is Asking for Trouble 1 have a question about dovetails. I want to make a couple items for my granddaughter: an old-fashioned hooded cradle with canted sides (life-size, not doll) and a frame-and-panel hope chest. I Ve cut dovetails on silverware trays with canted sidesand learned that the grain of the tails issupposed to run parallel with the wood so as not to weaken the tails. However, I saw an antique mahogany cradle (way out of my price range) that did the opposite. The grain in the tails ran perpendicular to the angle of slope without a single broken tail. Which is correct? Second, I ran across a frame-and-panel chest in a shop with the corner stiles joined with dovetails. Of course, that makes the direction of the tail perpendicular to the grain of the wood. That should be a really bad idea, yet the joints are holding up extremely well. Can I safely do the same with my chest? — Gary Long, Norfolk,Virginia It's common to see all sorts of st range const ructions in antique furniture. Just like today, there wasn't "one way" to do things back then. That said, cutt ing dovetails on edge grain is almost always asking for trouble. The joint may go together. It may hold up in use (perhaps due to the surroundingassembhes in the piece). But it is a compromised joint and does not exploit the inherent strength in a properly made dovetail. And in some cases, such as the cradle you described, there could be a cross-grain construction. That joint could be stressed every season when the wood expands and contracts. My recommendation: Keepyour tails and pins parallel to the grain of your wood. — Christopher Sclnvarz, editor What's Causing Cupping? I'm an experienced woodworker who hasjust started a small furniture shop. 1 love building chests, and 1 recently started to market a small box. 1 have had some cupping issues with the tops (usually a two-piece edge glue-up) and want to know your thoughts. I have avoided using cleats up until now. Will it always be risky not using cleats of some type, even on a small top? Or do you have any hints that would ensure more success? I have extensive history with gluing. 1 lowever, this smaller-scale project is fairly new. It's a high-end box with a natural finish. I'm hoping to keep the top on the lighter/simple side. My shop conditions were less than ideal as far as temperature/moisture consistency in comparison to home conditions-which is probably the cause oft he cuppi ngas much asanything. In my new shop those conditions have changed, but are there other things that could be causing the problem? — Christopher Perry, via e-mail There are a couple things that might be causing your problems. First, are you using air-dried or kiln-dried lumber? Air dried is usually a bit higher moisture content than kiln-dried lumber, and I believe air-dried stock is a bit less stable (due to COMINUID ON I'ACt 16 Angle both ends 14 ■ Popular Woodworking November 2008 IllUStRAIIONBYNAYtSSHANlSY |