Popular Woodworking 2008-11 № 172, страница 10

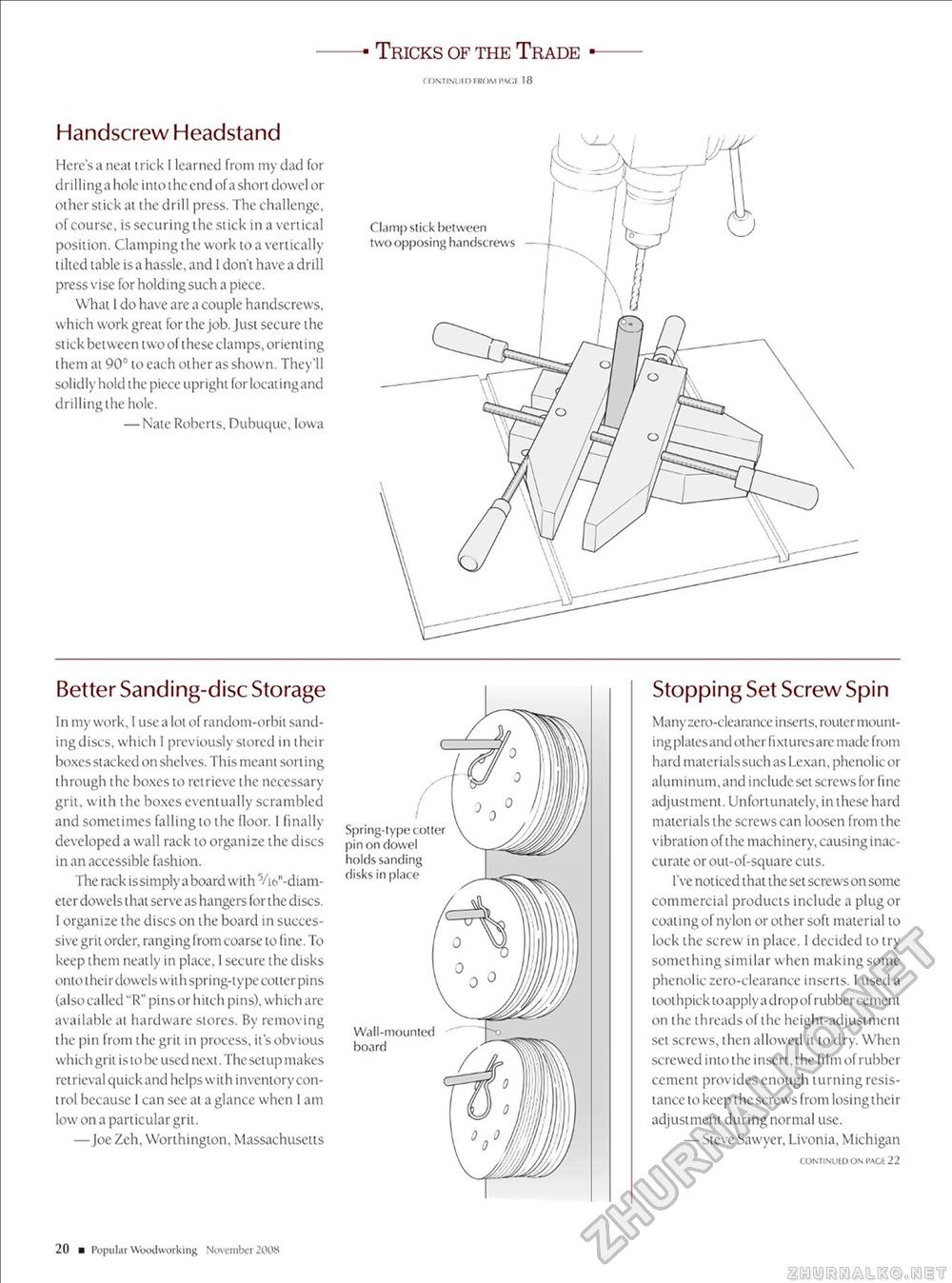

Tricks of the Trade ( OMINUFOFROM PAtif 18 Handscrew Headstand Here's a neal trick I learned from my dad for drillinga hole into theend ofashort dowel or other stick at the drill press. The challenge, of course, is securing the stick in a vertical position. Clamping the work to a vertically tilted table is a hassle, and I don't have a drill press vise for holding such a piece. What I do have are a couple handscrews, which work great for the job. Just secure the stick between two of these clamps, orienting thetn at 90° to each other as shown. They'll solidly hold the piece upright for locating and drilling the hole. — Nate Roberts, Dubuque, Iowa Better Sanding-disc Storage In my work. I use a lot of random-orbit sanding discs, which I previously stored in their boxes slacked on shelves. Th is meant sort i ng through ilie boxes to retrieve the necessary grit, with the boxes eventually scrambled and sometimes falling to the floor. I finally developed a wall rack to organize the discs in an accessible fashion. The rack issimply aboard with Yi6"-diam-eter dowels lhai serve as hangers for the discs. I organize the discs on ihe board in successive grii order, ranging from coarse to fine. To keep them neatly in place, I secure ihe disks ontotheirdowelswiih spring-type cotter pins (also called "R" pinsor hitch pins), which are available at hardware stores. By removing the pin from the grit in process, it'sobvious which grit is to be used next. The setup makes retrieval quickand helps with inventory control because I can see ai a glance when 1 am low on a particular grit. — Joe Zeh, Worthingion, Massachusetts Clamp stick between two opposing handscrews / Spring-type cotter pin on dowel holds sanding disks in place Wall-mounted board Stopping Set Screw Spin Many zero-clearance inserts, router mounting platesand other fixturesare made from hard materialssuch as Lexan, phenolic or aluminum, and include set screws for fine adjustment. Unfortunately, in these hard materials the screws can loosen from the vibration of the machinery, causing inaccurate or out-of-square cuts. I've noticed that the set screws on some commercial products include a plug or coating of nylon or other soft material to lock the screw in place. I decided to try something similar when making some phenolic zero-clearance inserts. I used a toot h pick to apply a d rop of r ubber ceme n t on the threads of the height-adjustment set screws, then allowed it to dry. When screwed into the i nsert, t he fi I m of rubber cement provides enough turning resistance to keep the screws from losing their adjustment during normal use. — Steve Sawyer, Livonia, Michigan CONTINUED ON I'ACt 22 20 a Popular Woodworking November 2008 |