Popular Woodworking 2009-08 № 177, страница 41

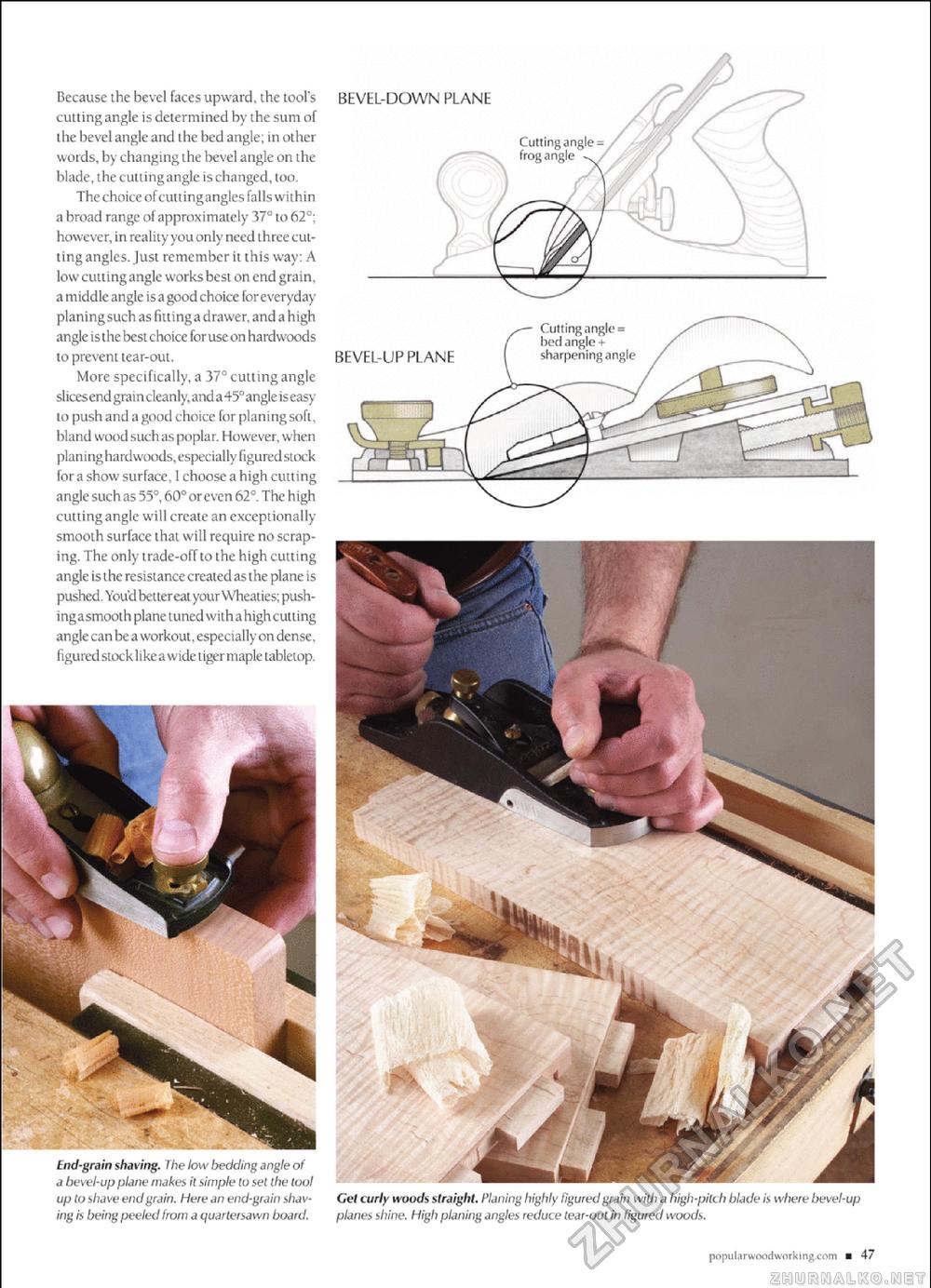

Because the bevel faces upward, the tool's cutting angle is determined by the sum of the bevel angle and the bed angle, in other words, by changing the bevel angle on the blade, the cutting angle is changed, too Thechoice of cutting angles fallswithin a broad range of approximately 37° to 62°; however, in realiLy you only need three cutting angles. Just remember it this way: A low cutting angle works best on end grain, a middle angle is a good choice for everyday planing such as fitting a drawer, and a high angleisthebestchoice foruseon hardwoods lo prevent tear-out. More specifically, a 37° cutting angle slices end gra i n cleanly, and a 45° angle is easy to push and a good choice for planing so ft, bland wood suchas poplar. However, when pi ani ng hardwoods, especially figured stock for a show surface, 1 choose a high cutting angle suchas 55°, 60° or even 62°. The high cutting angle will create an exceptionally smooth surface that will require no scraping. The only trade-off to the high cutting angle is the resistance created asthe plane is pushed. You'dbettereat your Wheaties; push-ingasmooth plane tuned with a high cutting angle can be a workout, especially on dense, figured slock 1 ike a w ide t iger maple tabletop. End-grain shaving. The low bedding angle of a bevel-up plane makes it simple to set the tool up to shave end grain. Here an end-grain shaving is being peeled from a quartersawn board. Get curly woods straight. Planing highly figured grain with a high-pitch blade is where bevel-up planes shine. High planing angles reduce tear-out in figured woods. BEVEL-DOWN PLANE Cutting anfile = popul a rwoodwork ing.com ■ 47 |