Popular Woodworking 2009-08 № 177, страница 52

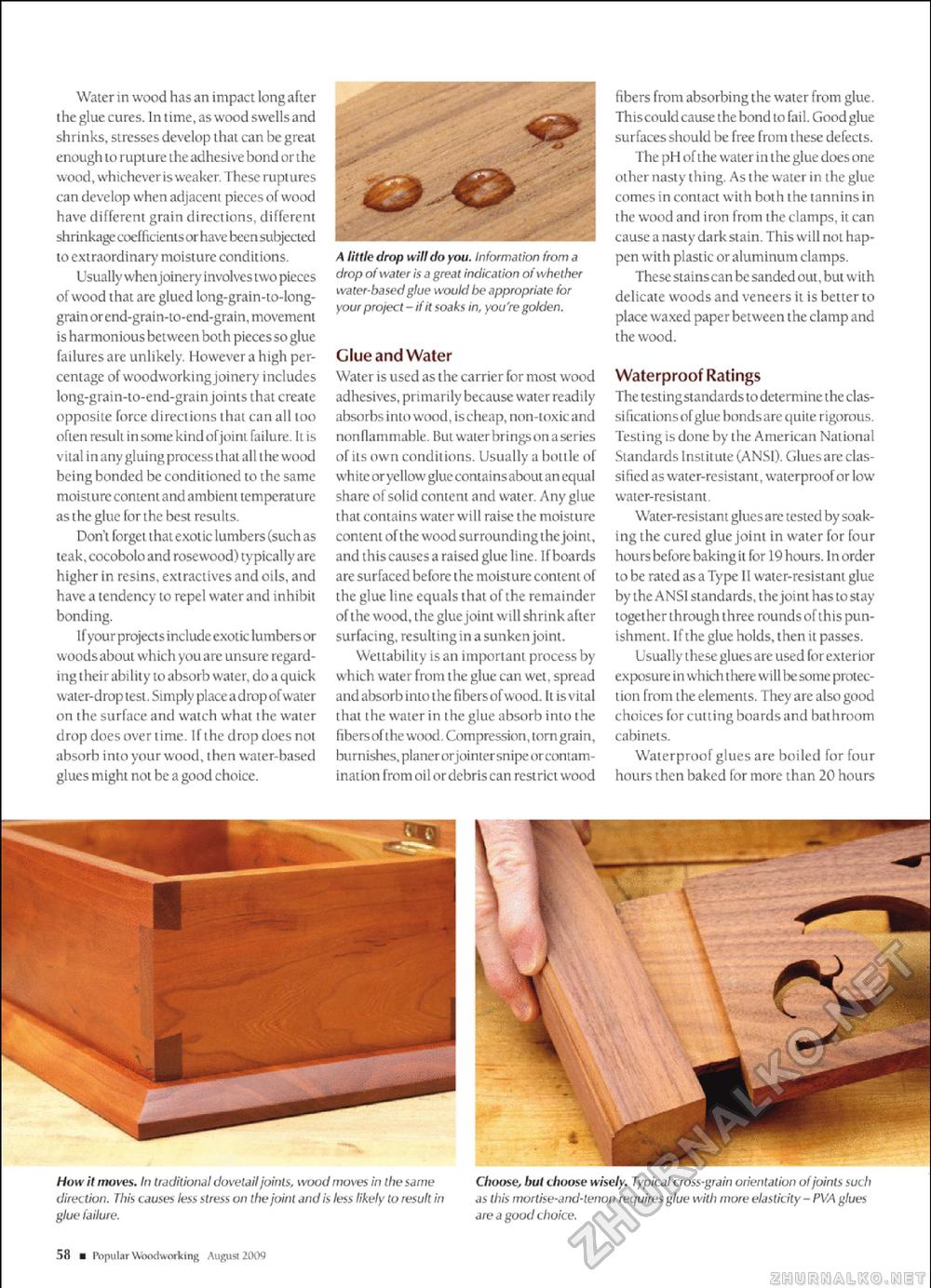

Water in wood hasan impact longafter the glue cures. In time, as wood swells and shrinks, stresses develop that can be great enough to rupture the adhe sive bond or the wood, whicheveris weaker, These ruptures can develop when adjacent pieces of wood have different grain directions, different shrinkage coefficients or have beensubjected to extraordinary moisture conditions. Usually when joinery involves two pieces ofwood that are glued long-grain-to-long-grain or end-grain-to-end-grai n, moveme nt is harmonious between both pieces so glue failures are unlikely. However a high percentage of woodworkingjoinery includes long-grain-to-end-grainjoints that create opposite force d irections I hat can all loo often result in some kind ofjoint failure. It is vital many gluing process that all I he wood being bonded be conditioned to the same moisture content and ambient temperature as the glue (or the best results. Don't forget that exotic lumbers (such as leak.cocobolo and rosewood) typically are higher in resins, extractives and oils, and have a tendency to repel water and inhibit bonding. If your projects include exotic lumbers or woods about which you are unsure regarding their ability to absorb water, do a quick water-drop test. Simply place a drop of water on the surface and watch what the water drop does overtime. If the drop does noi absorb into your wood, then water-based glues might not be a good choice. A little drop will do you. Information from a drop of water is a great indication of whether water-based glue would be appropriate for your project ~ if it soaks in, you're golden. Glue and Water Water is used as the carrier for most wood adhesives, primarily because water readily absorbs into wood, is cheap, non-toxic and non flammable. But water brings on a series of its own conditions. Usually a bottle of white oryellow glue containsabout an equal share of solid content and water. Any glue that contains water will raise the moisture content ofthe wood surroundingthe joint, and this causes a raised glue line. If boards are surfaced before the moisture content of the glue line equals that ofthe remainder ofthe wood, the glue joint will shrinkafter surfacing, resulting in a sunken joini. Wettability is an important process by which water from the glue can wet, spread and absorb into the fibers of wood. It is vital that Lhe water in the glue absorb into the fibe rs of Lhe wood. Compression, tor n grai n, burnishes, planer orjointer snipe or contamination from oil or debris can restrict wood fibers from absorbing the water from glue. This could cause the bond to fail. Good glue surfaces should be free from these defects. The pH ofthe water in the glue does one other nasty thing. As the water in the glue comes in contact with both the tannins in the wood and iron from the damps, it can cause a nasty dark stain. Thiswill noL happen with plastic or aluminum clamps. These stainscanbe sanded o ut, but w iih delicate woods and veneers it is better to place waxed paper between the clamp and the wood. Waterproof Ratings The testingstandardstodetermine the classification s of glue bonds are qui te rigorou s. Teslingis done by the American National Standards Institute (ANSI). Glues are classified as water-resisLant, waterproof or low water-resislant, Water-resistant glues are tested by soaking the cured glue joint in water for four hours before baking it for 19 hours. In order to be rated as a Type 11 water-resistant glue by the ANSI standards, the joint has to stay together through three rounds of this punishment. if the glue holds, then it passes. Usually these gluesare used for exterior exposure in which there will be some protection from the elements. They are also good choices for cutting boards and bathroom cabinets. Waterproof glues are boiled for four hours then baked for more than 20 hours How it moves. In traditional dovetail joints, wood moves in the same direction. This causes less stress on the joint and is less likely to result in glue failure. Choose, but choose wisely. Typical cross-grain orientation of joints such as this mortise-and-tenon requires glue with more elasticity - PVA glues are a good choice. 58 ■ Popular Woodworking Augusi2009 |