Popular Woodworking 2009-08 № 177, страница 53

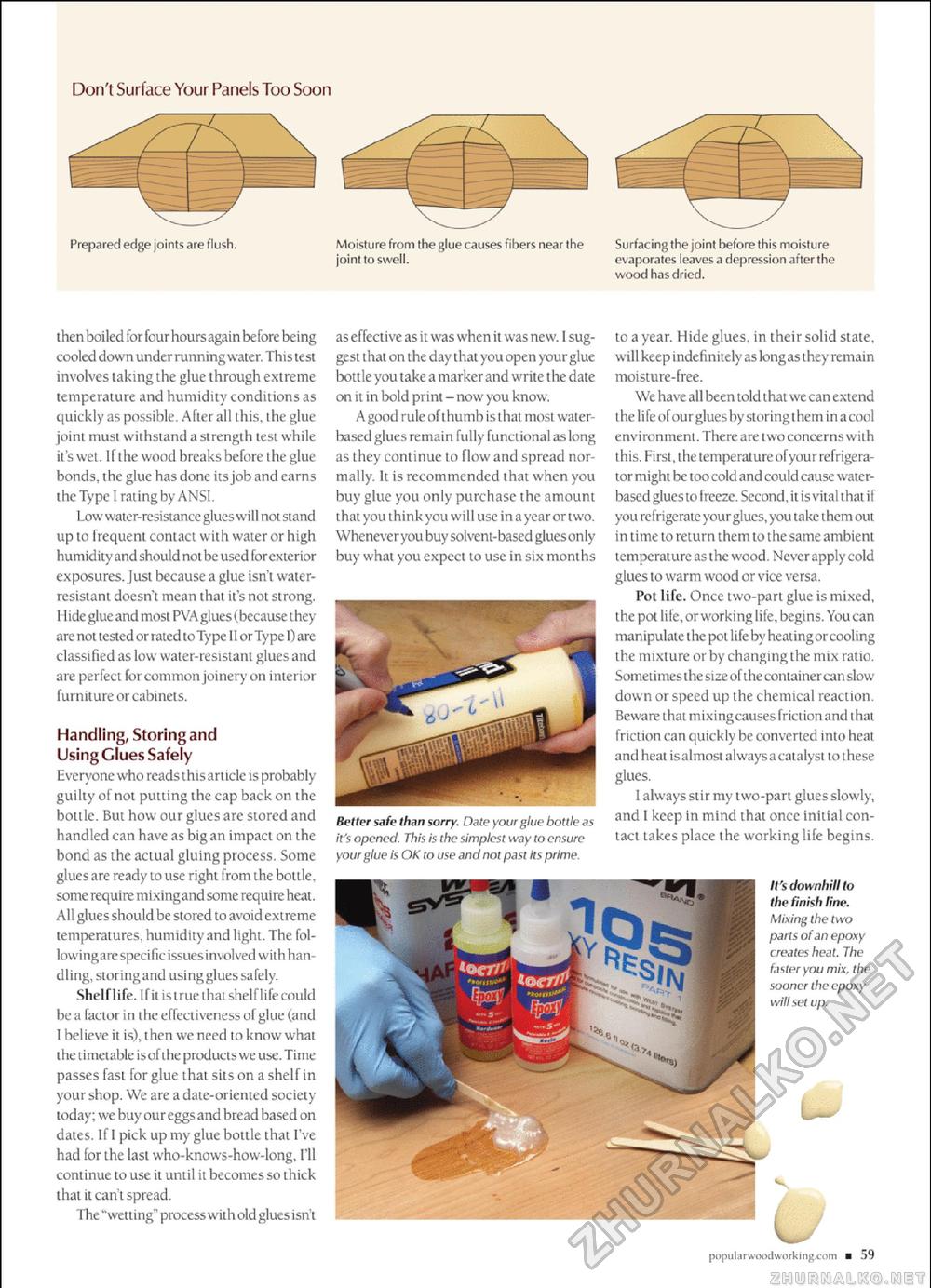

Surfacing the joint before this moisture evaporates I eavesa depression after the wood has dried. Don't Surface Your Panels Too Soon Prepared edge joints are flush. Moisture from the glue causes fibers near the ioint to swell. I hen boiled for four hours again be fore be ing cooled down under running water. Thistest involves taking the glue through extreme temperature and humidity conditions as quickly as possible. After all this, the glue joint must withstand a strength test while it's wet. If the wood breaks before the glue bonds, the glue has done its job and earns the Type I ratingby ANSI. Low water-resistance glues will not stand up lo frequent contact with water or high humidity and should not be used forexterior exposures. Just because a glue isn't water-resistant doesn't mean that it's not strong. Hide glue and most PVA glues (because they are not tested or rated to Type II or Type 1) are classified as low water-resislant glues and are perfect for common joinery on interior furniture orcabinets. Handling, Storing and Using Clues Safely Everyone who reads this article is probably gui liy of not putting the cap back on the bottle. But how our glues are stored and handled can have as big an impact on the bond as the actual gluing process. Some glues are ready lo use right from the bottle, some require mixingand some require heat. All glues should be stored to avoid extreme temperatures, humidity and light. The fol-lowingare specific issues involved with handling, storingand using glues safely. Shelflife. Ifilistrue that shelflife could be a factor in i he effectiveness of glue (and I believe it is), then we need to know what the timetable is ofthe products we use. Time passes fast for glue that sits on a shelf in your shop. We are a date-oriented society tod ay; we buy on r eggs and bread based on dates. !f l pick up my glue bottle that I've had for the lasi who-knows-how-long, I'll continue to use it until il becomes so thick thai it can't spread. The "wetting" process with old glues isn't as effective as it was when il was new. I suggest that on the day that you open your glue bottle you lake a marker and write lhe date on it in bold pri nl - now you know. A good rule of thumb isthat most water-based glues remain fully funclionalas long as they continue to flow and spread normally. It is recommended that when you buy glue you only purchase the amount that you think you will use in a year or two. Wheneveryou buy solvent-based glues only buy what you expect to use in six months Better safe than sorry. Date your glue bottle as it's opened. This is the simplest way to ensure your glue is OK to use and not past its prime. to a year. Hide glues, in their solid slate, will keep indefinitely as long as they remain moisture-free. We have al I been told that we can extend the life of our glues by storingthem inacool environment. Thereare two concerns with this. First, the temperature of your refrigera-tormight be too cold and could cause water-based glues tofreeie. Second, it is vital thatif you refrigerate your glues, you take them out in time to return them to the same ambient temperature as the wood. Never apply cold glues to warm wood or vice versa, Pol life. Once two-part glue is mixed, the pot life,orworkinglife,begins. You can man ipulate the pot 1 i fe by heating or cooling the mixture or by changing the mix ratio. Somelimesihe size of the container canslow down or speed up the chemical reaction. Beware thai mixing causes friction and that friction can quickly be converted into heat and heal isalmosl always a catalyst to these glues. 1 always stir my iwo-pari glues slowly, and 1 keep in mind that once initial contact lakes place the working life begins. It's dow nhill to the finish line. Mixing the two parts of an epoxy creates heal. The faster you mix, the sooner the epoxy will set up. popul a rwoodwork ing.com ■ 59 |