Popular Woodworking 2009-11 № 179, страница 55

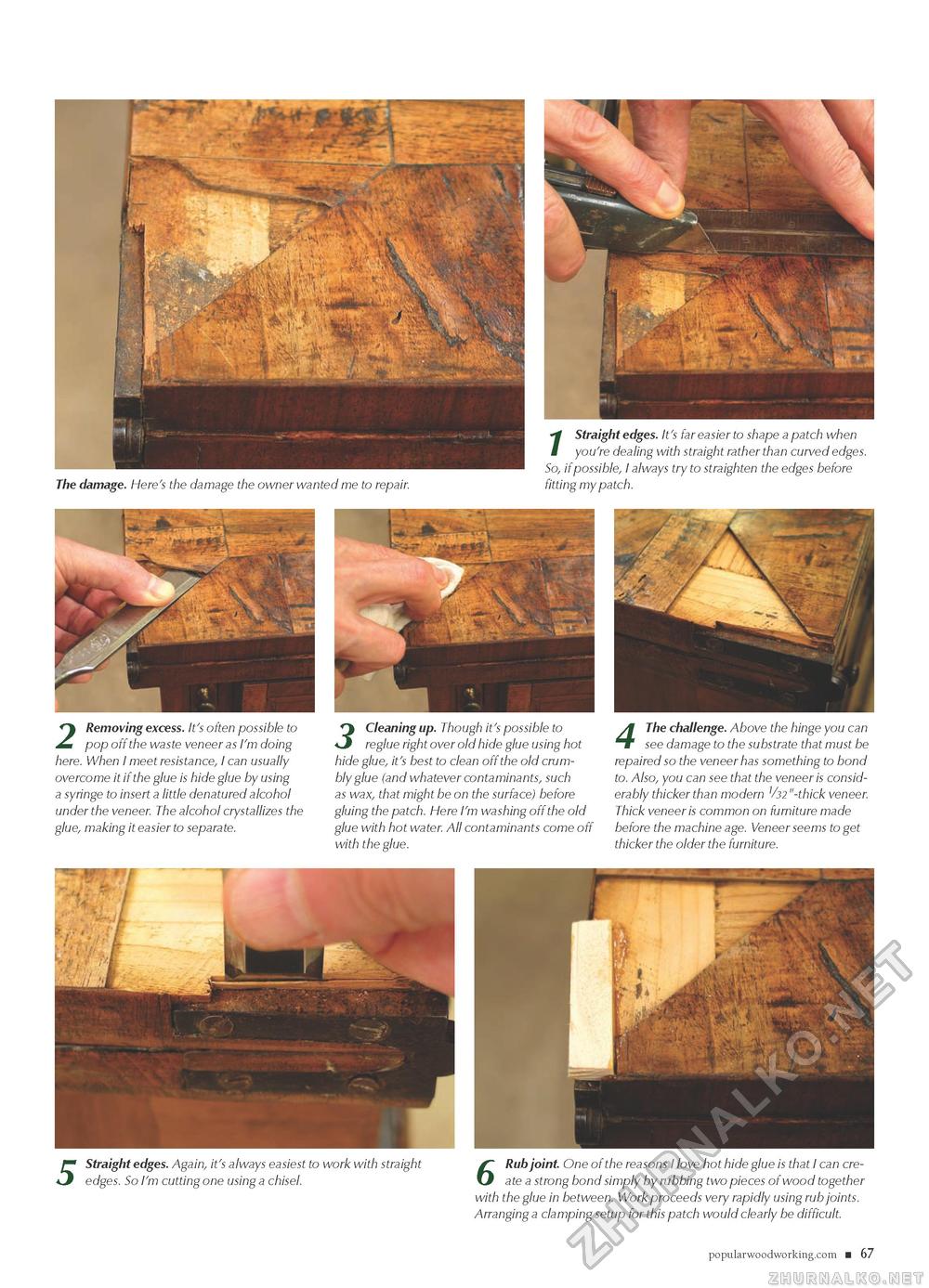

The damage. Here's the damage the owner wanted me to repair. /.Straight edges. It's far easier to shape a patch when you're dealing with straight rather than curved edges. So, if possible, I always try to straighten the edges before fitting my patch. 2 Removing excess. It's often possible to pop off the waste veneer as I'm doing here. When I meet resistance, I can usually overcome it if the glue is hide glue by using a syringe to insert a little denatured alcohol under the veneer. The alcohol crystallizes the glue, making it easier to separate. O Cleaning up. Though it's possible to *J reglue right over old hide glue using hot hide glue, it's best to clean off the old crumbly glue (and whatever contaminants, such as wax, that might be on the surface) before gluing the patch. Here I'm washing off the old glue with hot water. All contaminants come off with the glue. 4 The challenge. Above the hinge you can see damage to the substrate that must be repaired so the veneer has something to bond to. Also, you can see that the veneer is considerably thicker than modern V32 "-thick veneer. Thick veneer is common on furniture made before the machine age. Veneer seems to get thicker the older the furniture. 5 Straight edges. Again, it's always easiest to work with straight edges. So I'm cutting one using a chisel. 6 Rub joint. One of the reasons I love hot hide glue is that I can create a strong bond simply by rubbing two pieces of wood together with the glue in between. Work proceeds very rapidly using rub joints. Arranging a clamping setup for this patch would clearly be difficult. popularwoodworking.com ■ 55 |