16 - Custonize Your Radial Arm Saw, страница 30

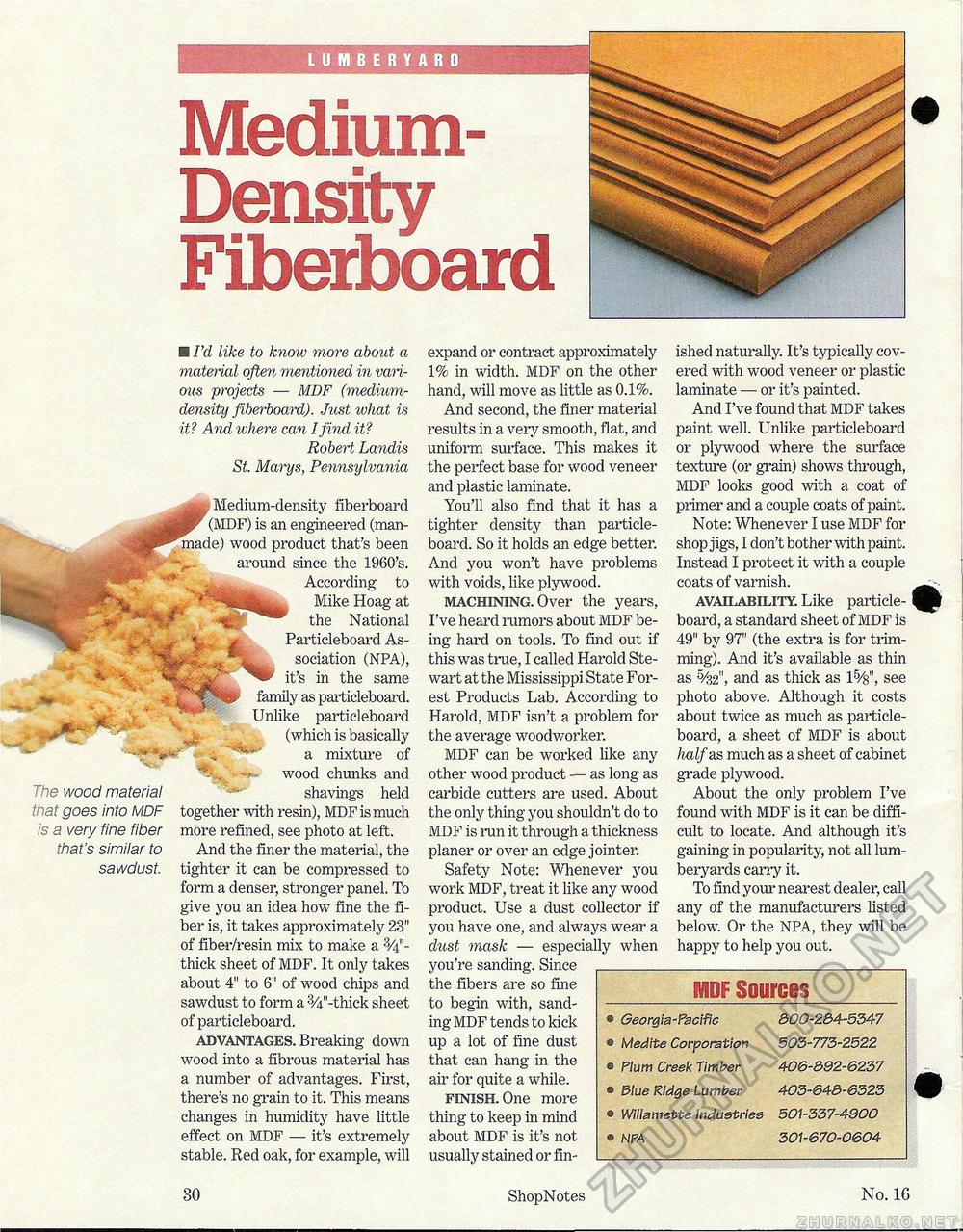

LUMBERYARD Medium-DensityFiberboardThe wood material that goes into MDF is a very fine fiber that's similar to sawdust. ■ I'd like to know more about a material often mentioned in various projects — MDF (medium-density fiberboard). Just what is it? And ■where can I find it? Robert Landis St. Marys, Pennsylvania Medium-density fiberboard (MDF) is an engineered (man-made) wood product that's been around since the 1960's. According to Mike Hoag at the National Particleboard Association (NPA), it's in the same family as particleboard. Unlike particleboard (which is basically a mixture of wood chunks and shavings held together with resin), MDF is much more refined, see photo at left. And the finer the material, the tighter it can be compressed to form a denser, stronger panel. To give you an idea how fine the fiber is, it takes approximately 23" of fiber/resin mix to make a thick sheet of MDF. It only takes about 4" to 6" of wood chips and sawdust to form a 3/4"-thick sheet of particleboard. advantages. Breaking down wood into a fibrous material has a number of advantages. First, there's no grain to it. This means changes in humidity have little effect on MDF — it's extremely stable. Reel oak, for example, will expand or contract approximately 1% in width. MDF on the other hand, will move as little as 0.1%. And second, the finer material results in a very smooth, flat, and uniform surface. This makes it the perfect base for wood veneer and plastic laminate. You'll also find that it has a tighter density than particleboard. So it holds an edge better. And you won't have problems with voids, like plywood. machining. Over the years, I've heard rumors about MDF being hard on tools. To find out if this was true, I called Harold Stewart at the Mississippi State Forest Products Lab. According to Harold, MDF isn't a problem for the average woodworker. MDF can be worked like any other wood product — as long as carbide cutters are used. About the only thing you shouldn't do to MDF is run it through a thickness planer or over an edge jointer. Safety Note: Whenever you work MDF, treat it like any wood product. Use a dust collector if you have one, and always wear a dust mask — especially when you're sanding. Since the fibers are so fine to begin with, sanding MDF tends to kick up a lot of fine dust that can hang in the air for quite a while. finish. One more thing to keep in mind about MDF is it's not usually stained or fin ished naturally. It's typically covered with wood veneer or plastic laminate — or it's painted. And I've found that MDF takes paint well. Unlike particleboard or plywood where the surface texture (or grain) shows through, MDF looks good with a coat of primer and a couple coats of paint. Note: Whenever I use MDF for shop jigs, I don't bother with paint. Instead I protect it with a couple coats of varnish. ^^ availability. Like particle- ^^ board, a standard sheet of MDF is 49" by 97" (the extra is for trimming). And it's available as thin as 5/32", and as thick as l5/s", see photo above. Although it costs about twice as much as particleboard, a sheet of MDF is about half as much as a sheet of cabinet grade plywood. About the only problem I've found wTith MDF is it can be difficult to locate. And although it's gaining in popularity, not all lumberyards carry it. To find your nearest dealer, call any of the manufacturers listed below. Or the NPA, they will be happy to help you out.

30 ShopNotes No. 16 |

||||||||||||||