16 - Custonize Your Radial Arm Saw, страница 27

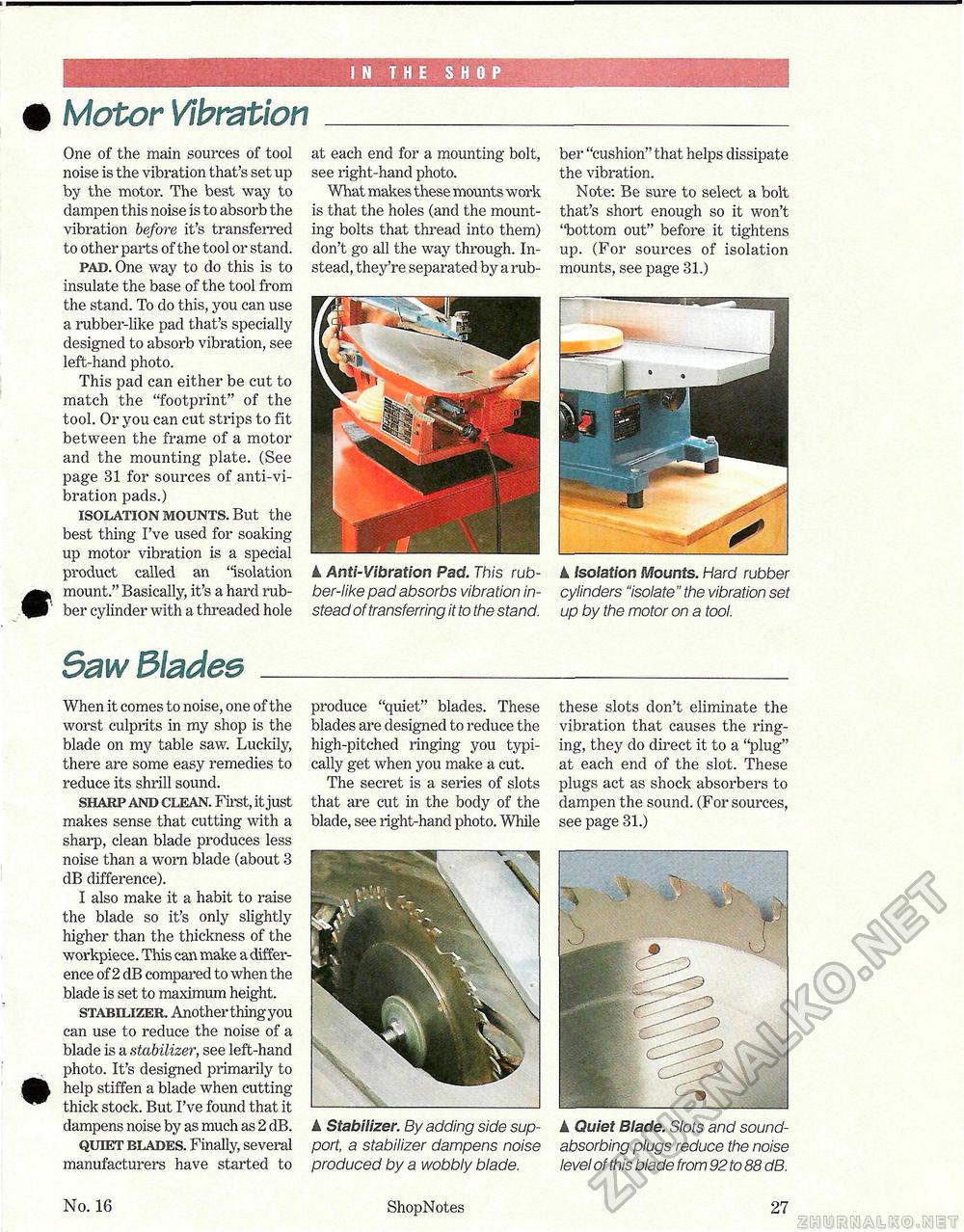

# Motor VibrationOne of the main sources of tool noise is the vibration that's set up by the motor. The best way to dampen this noise is to absorb the vibration before it's transferred to other parts of the tool or stand. pad. One way to do this is to insulate the base of the tool from the stand. To do this, you can use a rubber-like pad that's specially designed to absorb vibration, see left-hand photo. This pad can either be cut to match the "footprint" of the tool. Or you can cut strips to fit between the frame of a motor and the mounting plate. (See page 31 for sources of anti-vibration pads.) isolation mounts. But the best thing I've used for soaking up motor vibration is a special product called an "isolation mount." Basically, it's a hard rubber cylinder with a threaded hole at each end for a mounting bolt, see right-hand photo. What makes these mounts work is that the holes (and the mounting bolts that thread into them) don't go all the way through. Instead, they're separated by a rub- A Anti-Vibration Pad. This rubber-like pad absorbs vibration instead of transferring it to the stand. ber "cushion" that helps dissipate the vibration. Note: Be sure to select a bolt that's short enough so it wTon't "bottom out" before it tightens up. (For sources of isolation mounts, see page 31.) A isolation Mounts. Hard rubber cylinders "isolate" the vibration set up by the motor on a tool. Saw 3ladee_ When it comes to noise, one of the worst culprits in my shop is the blade on my table saw. Luckily, there are some easy remedies to reduce its shrill sound. sharp and clean. First, it just makes sense that cutting with a sharp, clean blade produces less noise than a worn blade (about 3 dB difference). I also make it a habit to raise the blade so it's only slightly higher than the thickness of the workpiece. This can make a difference of 2 dB compared to when the blade is set to maximum height. stabilizer. Another thing you can use to reduce the noise of a blade is a stabilizer, see left-hand photo. It's designed primarily to help stiffen a blade when cutting ^^ thick stock. But I've found that it dampens noise by as much as 2 dB. quiet blades. Finally, several manufacturers have started to produce "quiet" blades. These blades are designed to reduce the high-pitched ringing you typically get when you make a cut. The secret is a series of slots that are cut in the body of the blade, see right-hand photo. While A Stabilizer. By adding side support, a stabilizer dampens noise produced by a wobbly blade. these slots don't eliminate the vibration that causes the ringing, they do direct it to a "plug" at each end of the slot. These plugs act as shock absorbers to dampen the sound. (For sources, see page 31.) A Quiet Blade. Slots and sound-absorbing plugs reduce the noise level of this blade from 92 to 88 dB. No. 16 ShopNotes 27 |