16 - Custonize Your Radial Arm Saw, страница 24

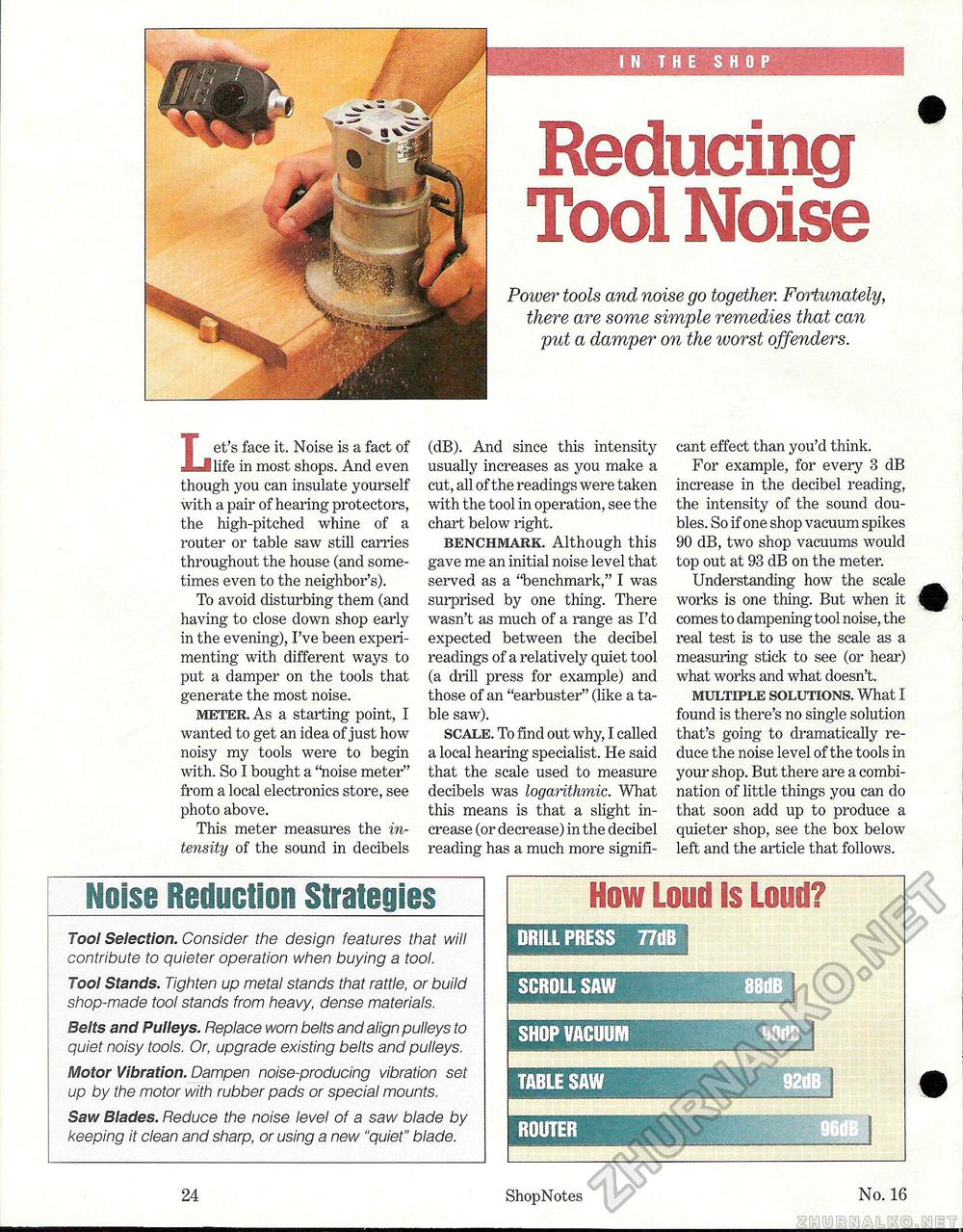

Reducing Tool Noise Power tools and noise go together. Fortunately, there are some simple remedies that can put a damper on the worst offenders. Let's face it. Noise is a fact of life in most shops. And even though you can insulate yourself with a pair of hearing protectors, the high-pitched whine of a router or table saw still carries throughout the house (and sometimes even to the neighbor's). To avoid disturbing them (and having to close down shop early in the evening), I've been experimenting with different ways to put a damper on the tools that generate the most noise. meter. As a starting point, I wanted to get an idea of just how noisy my tools were to begin with. So I bought a "noise meter" from a local electronics store, see photo above. This meter measures the intensity of the sound in decibels (dB). And since this intensity usually increases as you make a cut, all of the readings were taken with the tool in operation, see the chart below right. benchmark. Although this gave me an initial noise level that served as a "benchmark," I was surprised by one thing. There wasn't as much of a range as I'd expected between the decibel readings of a relatively quiet tool (a drill press for example) and those of an "earbuster" (like a table saw). scale. To find out why, I called a local hearing specialist. He said that the scale used to measure decibels was logarithmic. What this means is that a slight increase (or decrease) in the decibel reading has a much more signifi cant effect than you'd think. For example, for every 3 dB increase in the decibel reading, the intensity of the sound doubles. So if one shop vacuum spikes 90 dB, twro shop vacuums would top out at 93 dB on the meter. Understanding how the scale works is one thing. But when it comes to dampening tool noise, the real test is to use the scale as a measuring stick to see (or hear) what works and what doesn't. multiple solutions. What I found is there's no single solution that's going to dramatically reduce the noise level of the tools in your shop. But there are a combination of little things you can do that soon add up to produce a quieter shop, see the box below left and the article that follows. Noise Reduction StrategiesTool Selection. Consider the design features that will contribute to quieter operation when buying a tool. Tool Stands. Tighten up metal stands that rattle, or build shop-made tool stands from heavy, dense materials. Belts and Pulleys. Replace worn belts and align pulleys to quiet noisy tools. Or, upgrade existing belts and pulleys. Motor Vibration. Dampen noise-producing vibration set up by the motor with rubber pads or special mounts. Saw Blades. Reduce the noise level of a saw blade by keeping it clean and sharp, or using a new "quiet" blade. How Loud is Loud? drill press 77db scroll saw 88db 24 ShopNotes No. 16 |