16 - Custonize Your Radial Arm Saw, страница 26

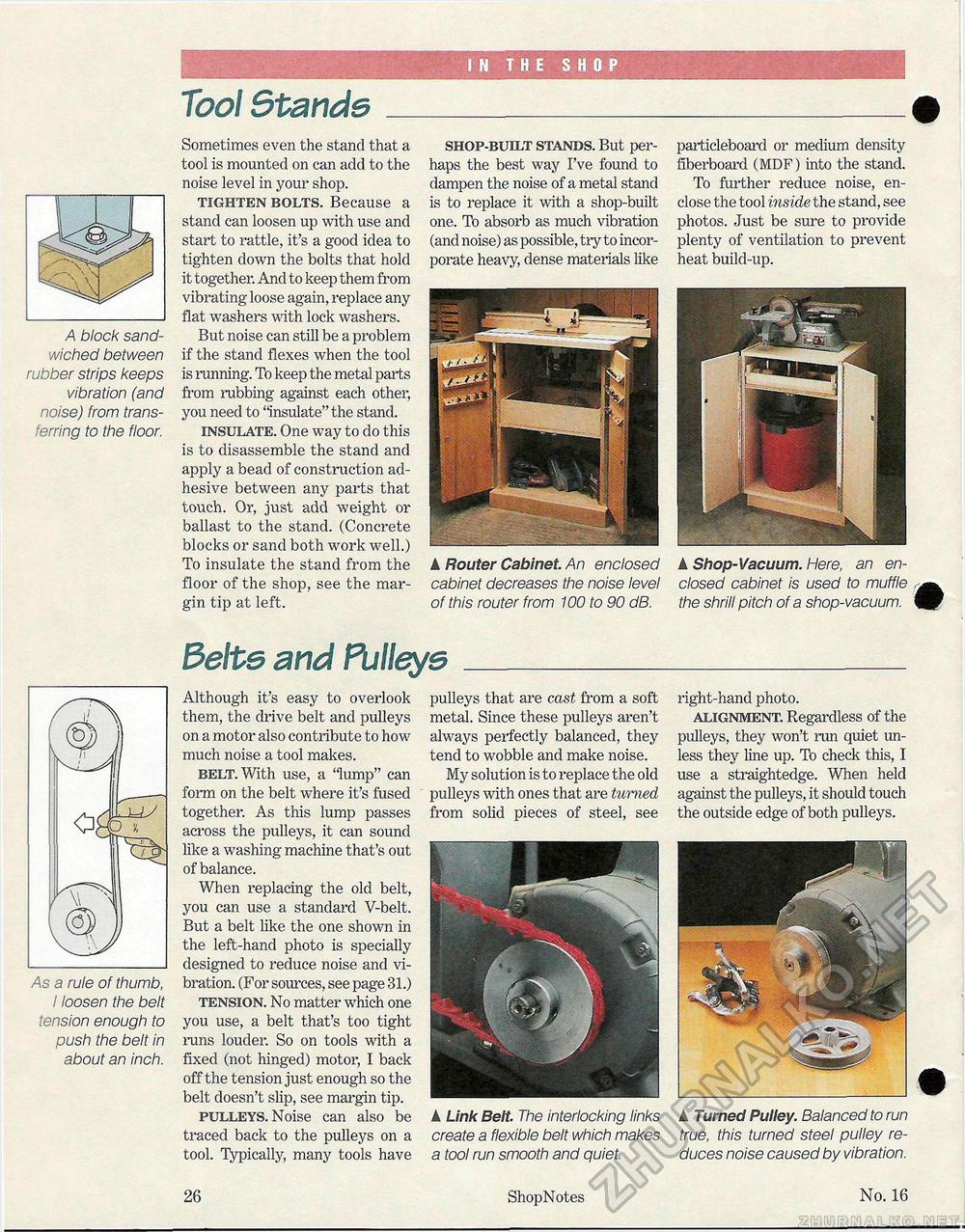

Tool 5tandsA block sandwiched between rubber strips keeps vibration (and noise) from transferring to the floor. Sometimes even the stand that a tool is mounted on can add to the noise level in your shop. tighten bolts. Because a stand can loosen up with use and start to rattle, it's a good idea to tighten down the bolts that hold it together. And to keep them from vibrating loose again, replace any flat washers with lock washers. But noise can still be a problem if the stand flexes when the tool is running. To keep the metal parts from rubbing against each other, you need to "insulate" the stand. insulate. One way to do this is to disassemble the stand and apply a bead of construction adhesive between any parts that touch. Or, just add weight or ballast to the stand. (Concrete blocks or sand both work well.) To insulate the stand from the floor of the shop, see the margin tip at left. shop-built stands. But perhaps the best way I've found to dampen the noise of a metal stand is to replace it with a shop-built one. To absorb as much vibration (and noise) as possible, try to incorporate heavy, dense materials like ▲ Router Cabinet An enclosed cabinet decreases the noise level of this router from 100 to 90 dB. particleboard or medium density fiberboard (MDF) into the stand. To further reduce noise, enclose the tool inside the stand, see photos. Just be sure to provide plenty of ventilation to prevent heat build-up. ▲ Shop-Vacuum. Here, an enclosed cabinet is used to muffle the shrill pitch of a shop-vacuum. 3elts and PulleyeAs a rule of thumb, I loosen the belt tension enough to push the belt in about an inch. right-hand photo. alignment. Regardless of the pulleys, they won't run quiet unless they line up. To check this, I use a straightedge. When held against the pulleys, it should touch the outside edge of both pulleys. ▲ Turned Pulley. Balanced to run true, this turned steel pulley reduces noise caused by vibration. Although it's easy to overlook them, the drive belt and pulleys on a motor also contribute to how much noise a tool makes. belt. With use, a "lump" can form on the belt where it's fused together. As this lump passes across the pulleys, it can sound like a washing machine that's out of balance. When replacing the old belt, you can use a standard V-belt. But a belt like the one shown in the left-hand photo is specially designed to reduce noise and vibration. (For sources, see page 31.) tension. No matter which one you use, a belt that's too tight runs louder. So on tools with a fixed (not hinged) motor, I back off the tension just enough so the belt doesn't slip, see margin tip. pulleys. Noise can also be traced back to the pulleys on a tool. Typically, many tools have pulleys that are cast from a soft metal. Since these pulleys aren't always perfectly balanced, they tend to wobble and make noise. My solution is to replace the old pulleys with ones that are turned from solid pieces of steel, see ▲ Link Belt. The interlocking links create a flexible belt which makes a tool run smooth and quiet. 26 ShopNotes No. 16 |