41 - Fold-Down Drafting Table, страница 14

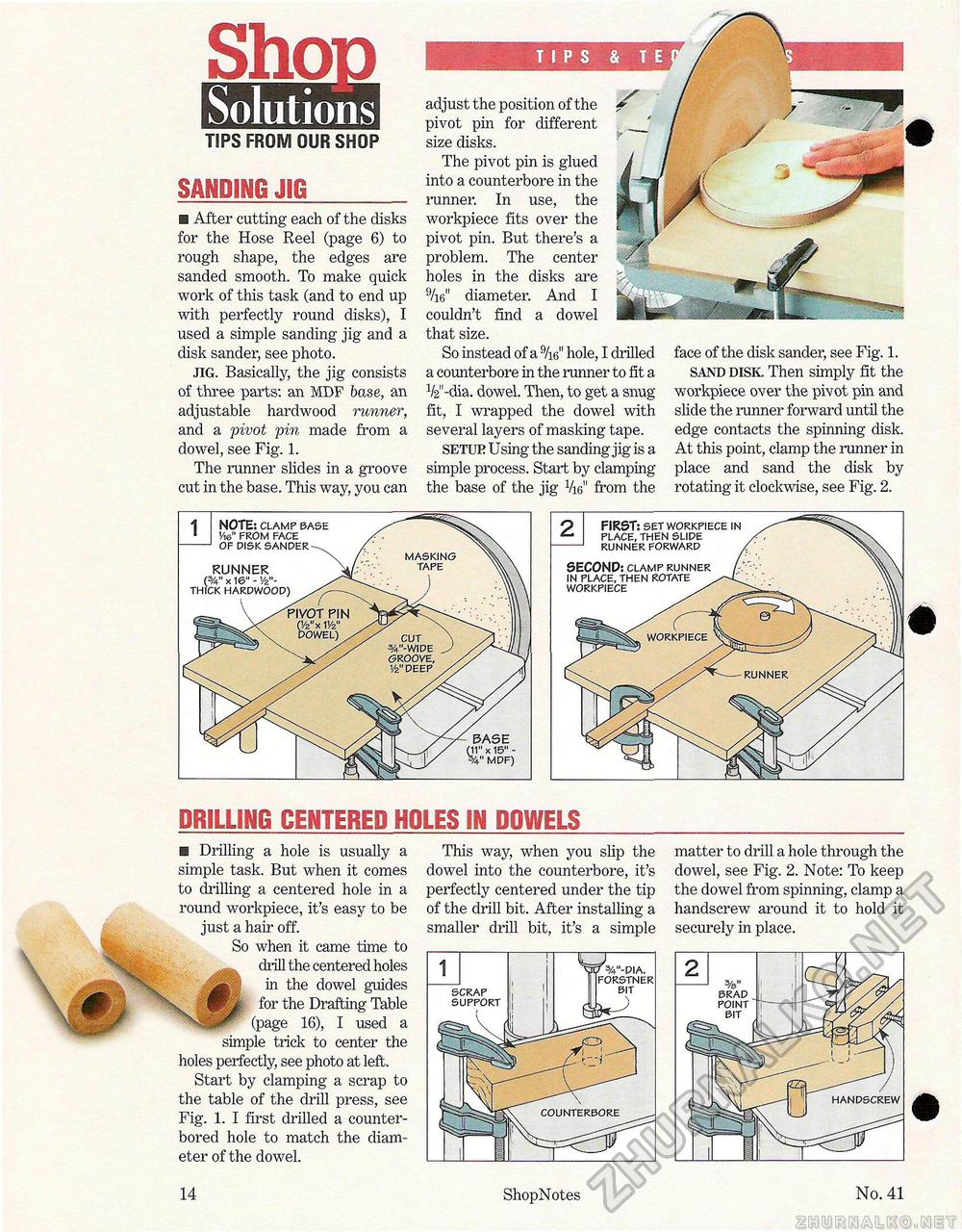

ShopISMBIfflil TIPS FROM OUR SHOP SANDING JIG_ ■ After cutting each of the disks for the Hose Reel (page 6) to rough shape, the edges are sanded smooth. To make quick work of this task (and to end up with perfectly round disks), I used a simple sanding jig and a disk sander, see photo. jig. Basically, the jig consists of three parts: an MDF base, an adjustable hardwood runner, and a pivot pin made from a dowel, see Fig. 1. The runner slides in a groove cut in the base. This way, you can TIPS & TI adjust the position of the pivot pin for different size disks. The pivot pin is glued into a counterbore in the runner. In use, the workpiece fits over the pivot pin. But there's a problem. The center holes in the disks are 9/i6n diameter. And I couldn't find a dowel that size. So instead of a 9/ie" hole, I drilled a counterbore in the runner to fit a V^'-dia. dowel. Then, to get a snug fit, I wrapped the dowel with several layers of masking tape. setup Using the sanding jig is a simple process. Start by clamping the base of the jig Vie" from the face of the disk sander, see Fig. 1. sand disk. Then simply fit the workpiece over the pivot pin and slide the runner forward until the edge contacts the spinning disk. At this point, clamp the runner in place and sand the disk by rotating it clockwise, see Fig. 2. NOTE: clamp base Vie" from face of disk sander RUNNER (3/4" X 16" - Vz"-thick hardwood) ? FIRST: set workpiece in - place, then slide - runner forward SECOND: clamp runner in place, then rotate workpiece DRILLING CENTERED HOLES IN DOWELS This way, when you slip the dowel into the counterbore, it's perfectly centered under the tip of the drill bit. After installing a smaller drill bit, it's a simple matter to drill a hole through the dowel, see Fig. 2. Note: To keep the dowel from spinning, clamp a handscrew around it to hold it securely in place. 14 ShopNotes ■ Drilling a hole is usually a simple task. But when it comes to drilling a centered hole in a round workpiece, it's easy to be just a hair off. So when it came time to drill the centered holes in the dowel guides for the Drafting Table (page 16), I used a simple trick to center the holes perfectly, see photo at left. Start by clamping a scrap to the table of the drill press, see Fig. 1. I first drilled a counter-bored hole to match the diameter of the dowel. No. 41 brad point bit |