43 - Build Your Own Dovetail Jig, страница 4

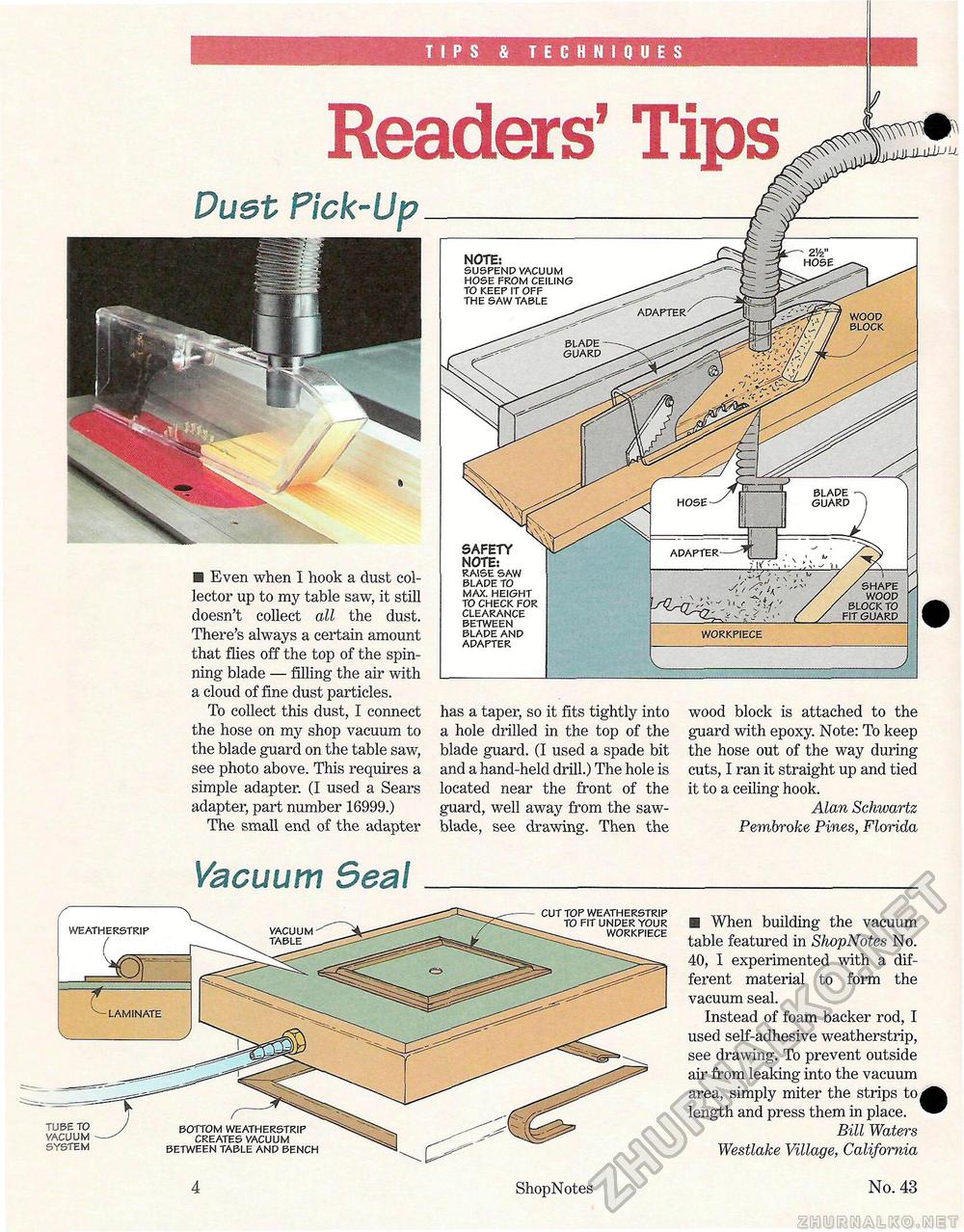

adapter blade guard HOSE adapter- TIPS & TECHNIQUES Readers' TipsDust Pick-Up■ Even when I hook a dust collector up to my table saw, it still doesn't collect all the dust. There's always a certain amount that flies off the top of the spinning blade — filling the air with a cloud of fine dust particles. To collect this dust, I connect the hose on my shop vacuum to the blade guard on the table saw, see photo above. This requires a simple adapter. (I used a Sears adapter, part number 16999.) The small end of the adapter has a taper, so it fits tightly into a hole drilled in the top of the blade guard. (I used a spade bit and a hand-held drill.) The hole is located near the front of the guard, well away from the saw-blade, see drawing. Then the wood block is attached to the guard with epoxy. Note: To keep the hose out of the way during cuts, I ran it straight up and tied it to a ceiling hook. Alan Schwartz Pembroke Pines, Florida SAFETY NOTE: raise saw blade to max. height to check for clearance between blade and adapter wood block NOTE: suspend vacuum hose from ceiling to keep it off the saw table blade guard / shape x wood block to fit guard workpiece Vacuum Seal- cut top weatherstrip to fit under your workpiece tube to vacuum system bottom weatherstrip creates vacuum between table and bench m When building the vacuum table featured in ShopNotes No. 40, I experimented with a different material to form the vacuum seal. Instead of foam backer rod, I used self-adhesive weatherstrip, see drawing. To prevent outside air from leaking into the vacuum area, simply miter the strips tOi length and press them in place. Bill Waters Westlake Village, California 4 ShopNotes No. 43 |