50 - Table Saw Workstation, страница 4

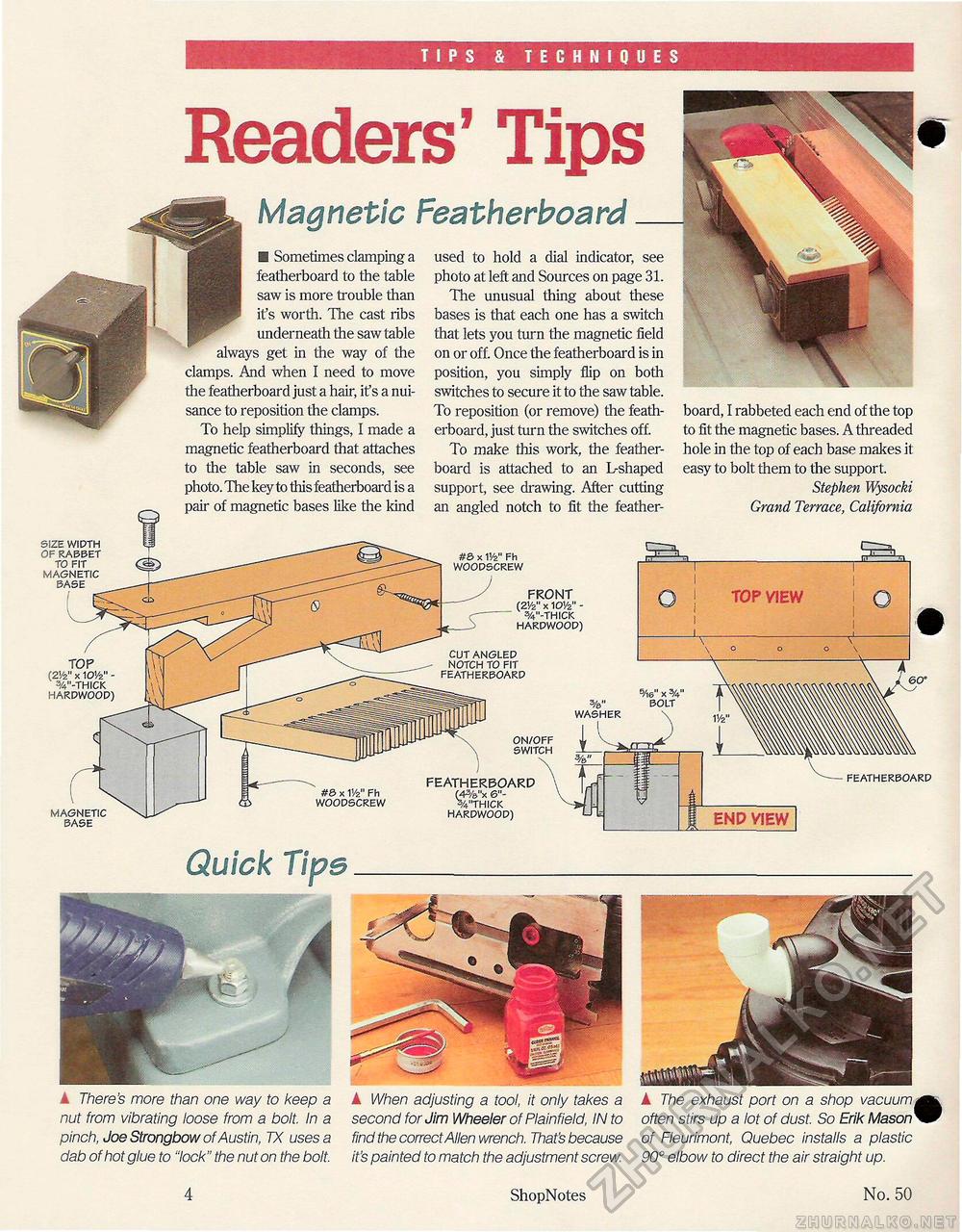

TIPS TECHNIQUES Readers' Tips Magnetic Featherboard ■ Sometimes clamping a featherboard to the table saw is more trouble than it's worth. The cast ribs underneath the saw table always get in the way of the clamps. And when I need to move the featherboard just a hair, it's a nuisance to reposition the clamps. To help simplify things, I made a magnetic featherboard that attaches to the table saw in seconds, see photo. The key to this featherboard is a pair of magnetic bases like the kind SIZE WIDTH OF RABBET TO FIT MAGNETIC BASE #S x 11/2" Fh WOODSCREW used to hold a dial indicator, see photo at left and Sources on page 31. The unusual thing about these bases is that each one has a switch that lets you turn the magnetic field on or off. Once the featherboard is in position, you simply flip on both switches to secure it to the saw table. To reposition (or remove) the featherboard, just turn the switches off. To make this work, the featherboard is attached to an L-shaped support, see drawing. After cutting an angled notch to fit the feather board, I rabbeted each end of the top to fit the magnetic bases. A threaded hole in the top of each base makes it easy to bolt them to the support. Stephen Wysocki Grand Terrace, California FRONT (2VZ" x 10Vz" - 3/4"-THICK HARDWOOD) CUT ANGLED NOTCH TO FIT FEATHERBOARD #8 x V/z" Fh WOODSCREW FEATHERBOARD (4%"x 6"-3/4"THICK HARDWOOD) Quick TipsA There's more than one way to keep a nut from vibrating loose from a bolt. In a pinch, Joe Strongbow of Austin, TX uses a dab of hot glue to "lock" the nut on the bolt. A When adjusting a tool, it only takes a second for Jim Wheeler of Plain field, IN to find the correct Allen wrench. That's because it's painted to match the adjustment screw. A The exhaust port on a shop vacuum, often stirs up a lot of dust. So Erik Mason' of Fleurimont, Quebec installs a plastic 90° elbow to direct the air straight up. 4 ShopNotes No. 50 |