79 - Slant Front Tool Cart, страница 11

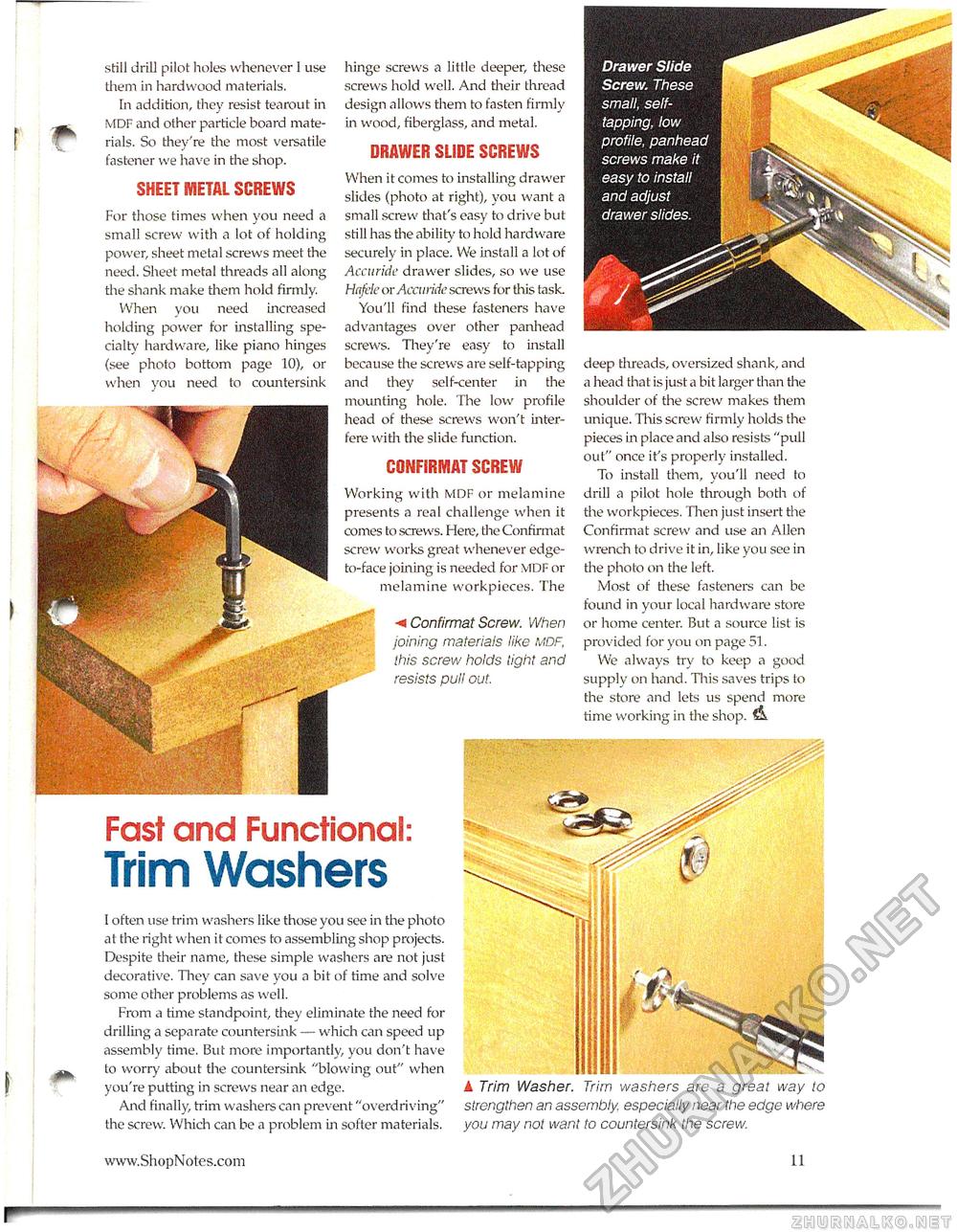

f www. ShopN otes.com 11 Fast and Functional: Trim WashersI often use trim washers like those you see in the photo at the right when it comes to assembling shop projects. Despite their name, these simple washers are not just decorative. They can save you a bit of time and solve some other problems as well. From a time standpoint, they eliminate the need for drilling a separate countersink — which can speed up assembly time. But more importantly, you don't have to worry about the countersink "blowing out" when you're putting in screws near an edge. And finally, trim washers can prevent "overdriving" the screw. Which can be a problem in softer materials. A Trim Washer. Trim washers are a great way to strengthen an assembly especially near the edge where you may not want to countersink the screw. CONFIRMAT SCREW Working with MDF or melamine presents a real challenge when it comes to screws. Here, the Confirmat screw works great whenever edge-to-face joining is needed for MDF or melamine workpieces. The < Confirmat Screw. When joining materials like MDF, this screw holds tight and resists pull out. Drawer Slide Screw. These small, self-tapping, low profile, panhead screws make it easy to install and adjust drawer slides. still drill pilot holes whenever I use them in hardwood materials. In addition, they resist tearout in MDF and other particle board materials, So they're the most versatile fastener we have in the shop. SHEET METAL SCREWS For those times when you need a small screw with a lot of holding power, sheet metal screws meet the need. Sheet metal threads all along the shank make them hold firmly. When you need increased holding power for installing specialty hardware, like piano hinges (see photo bottom page 10), or when you need to countersink hinge screws a little deeper, these screws hold well. And their thread design allows them to fasten firmly in wood, fiberglass, and metal. DRAWER SLIDE SCREWS When it comes to installing drawer slides (photo at right), you want a small screw that's easy to drive but still has the ability to hold hardware securely in place. We install a lot of Accuride drawer slides, so we use Hafsle or Accuride screws for this task. You'll find these fasteners have advantages over other panhead screws. They're easy to install because the screws are self-tapping and they self-center in the mounting hole. The low profile head of these screws won't interfere with the slide function. deep threads, oversized shank, and a head that is just a bit la rger than the shoulder of the screw makes them unique. This screw firmly holds the pieces in place and also resists "pull out" once it's properly installed. To install them, you'll need to drill a pilot hole through both of the workpieces. Then just insert the Confirmat screw and use an Allen wrench to drive it in, like you see in the photo on the left. Most of these fasteners can be found in your local hardware store or home center. But a source list is provided for you on page 51. We always try to keep a good supply on hand. This saves trips to the store and lets us spend more time working in the shop. ^ |