79 - Slant Front Tool Cart, страница 6

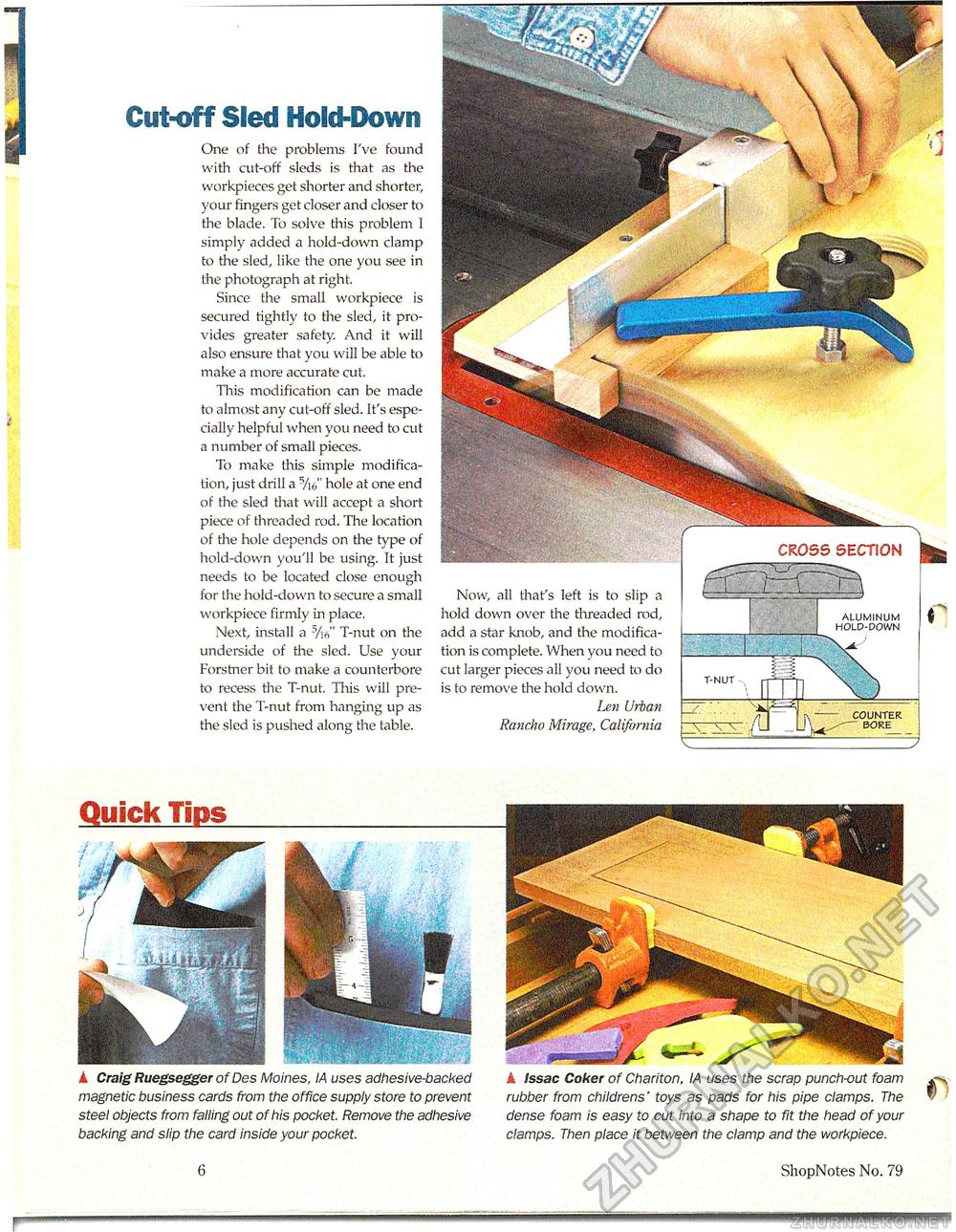

Cut-off Sled Hold-Down One of the problems I've found with cut-off sleds is that as the workpieces get shorter and shorter, your fingers get closer and closer to the blade. To solve this problem I simply added a hold-down clamp to the sled, like the one you see in the photograph at right. Since the small vvorkpiece is secured tightly to the sled, it provides greater safety. And it will also ensure that you will be able to make a more accurate cut. This modification can be made to almost any cut-off sled. It's especially helpful when you need to cut a number of small pieces. To make this simple modification, just drill a 5/i6" hole at one end of the sled that will accept a short piece of threaded rod. The local ion of the hole depends on the type of hold-down you'll be using. It just needs to be located close enough for the hold-down to secure a small workpiece firmly in place. Next, install a 5/i6" T-nut on the underside of the sled. Use your Forstner bit to make a counterbore to recess the T-nut. This will prevent the T-nut from hanging up as the sled is pushed along the table. Quick Tips A Craig Ruegsegger of Des Moines, I A uses adhesive-backed magnetic business cards from the office supply store to prevent steel objects from falling out of his pocket. Remove the adhesive backing and slip the card inside your pocket. A Issac Coker of Chariton, IA uses the scrap punch-out foam rubber from childrens' toys as pads for his pipe clamps. The dense foam is easy to cut into a shape to fit the head of your clamps. Then place it between the clamp and the workpiece. Now, all that's left is to slip a hold down over the threaded rod, add a star knob, and the modification is complete. When vou need to cut larger pieces all you need to do is to remove the hold down. Len Urban Rancho Mirage, California T-NUT 6 ShopNotes No. 79 |