81 - Ultimate Sharpening Station, страница 4

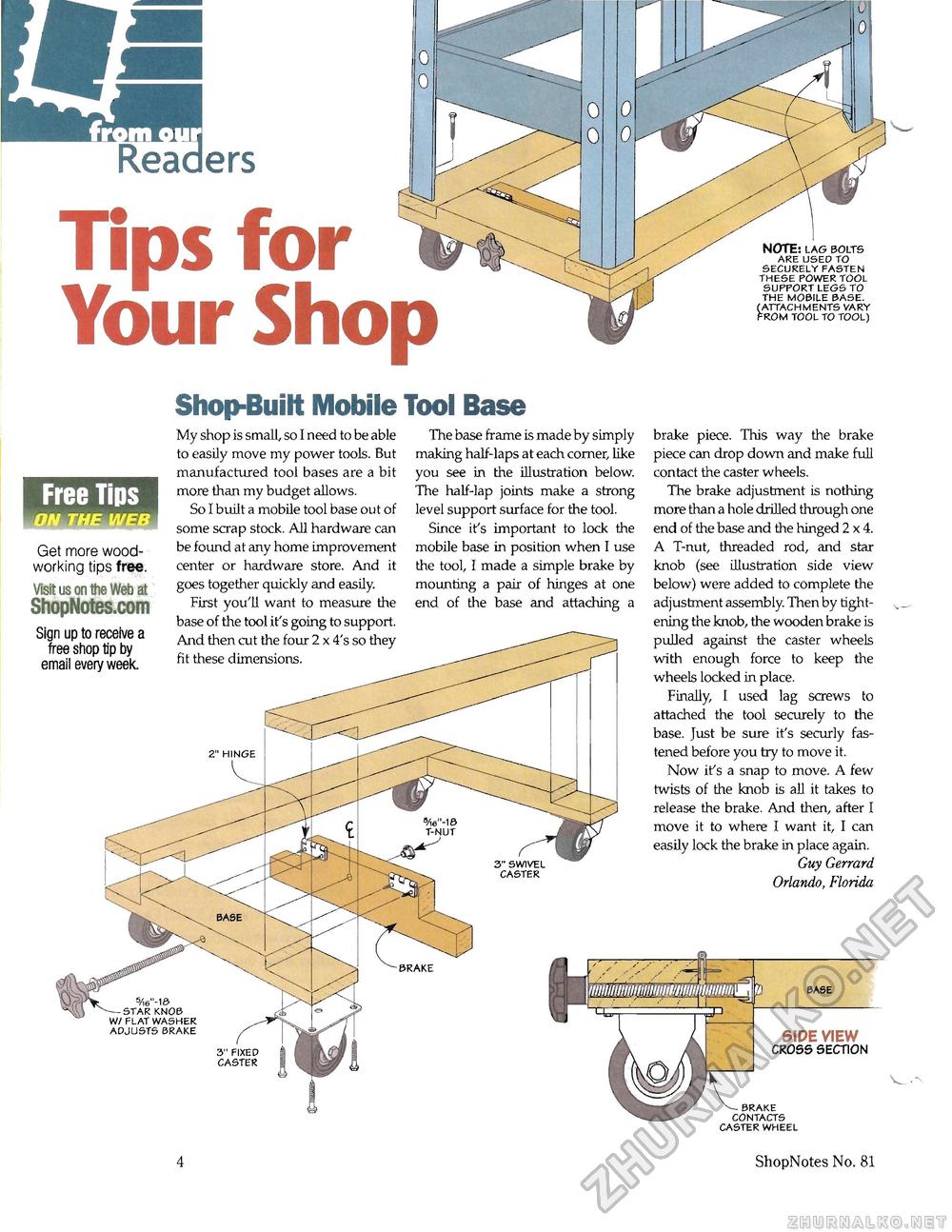

Readers Tips for Your Shop NOTE: LAG BOLTS ARE USED TO SECURELY FASTEN THESE POWER TOOL SUPPORT LEGS TO THE MOBILE BASE. ATTACHMENTS VARY ROM TOOL TO TOOL) Shop-Built Mobile Tool Base Free Tips wmwwTTBmwTw Get more woodworking tips free. Visit us on the Web at ShopNotes.com Sign up to receive a free shop tip by email every week. My shop is small, so I need to be able to easily move my power tools. But manufactured tool bases are a bit more than my budget allows. So I built a mobile tool base out of some scrap stock. All hardware can be found at any home improvement center or hardware store. And it goes together quickly and easily. First you'll want to measure the base of the tool it's going to support. And then cut the four 2 x 4's so they fit these dimensions. The base frame is made by simply making half-laps at each corner, like you see in the illustration below. The half-lap joints make a strong level support surface for the tool. Since it's important to lock the mobile base in position when I use the tool, I made a simple brake by mounting a pair of hinges at one end of the base and attaching a brake piece. This way the brake piece can drop down and make full contact the caster wheels. The brake adjustment is nothing more than a hole drilled through one end of the base and the hinged 2x4. A T-nut, threaded rod, and star knob (see illustration side view below) were added to complete the adjustment assembly. Then by tightening the knob, the wooden brake is pulled against the caster wheels with enough force to keep the wheels locked in place. Finally, I used lag screws to attached the tool securely to the base. Just be sure it's securly fastened before you try to move it. Now ifs a snap to move. A few twists of the knob is all it takes to release the brake. And then, after I move it to where I want it, I can easily lock the brake in place again. Guy Gerrard Orlando, Florida mMmmmmiigjz BASE side view CROSS SECTION BRAKE CONTACTS CASTER WHEEL 4 ShopNotes No. 81 |