84, страница 41

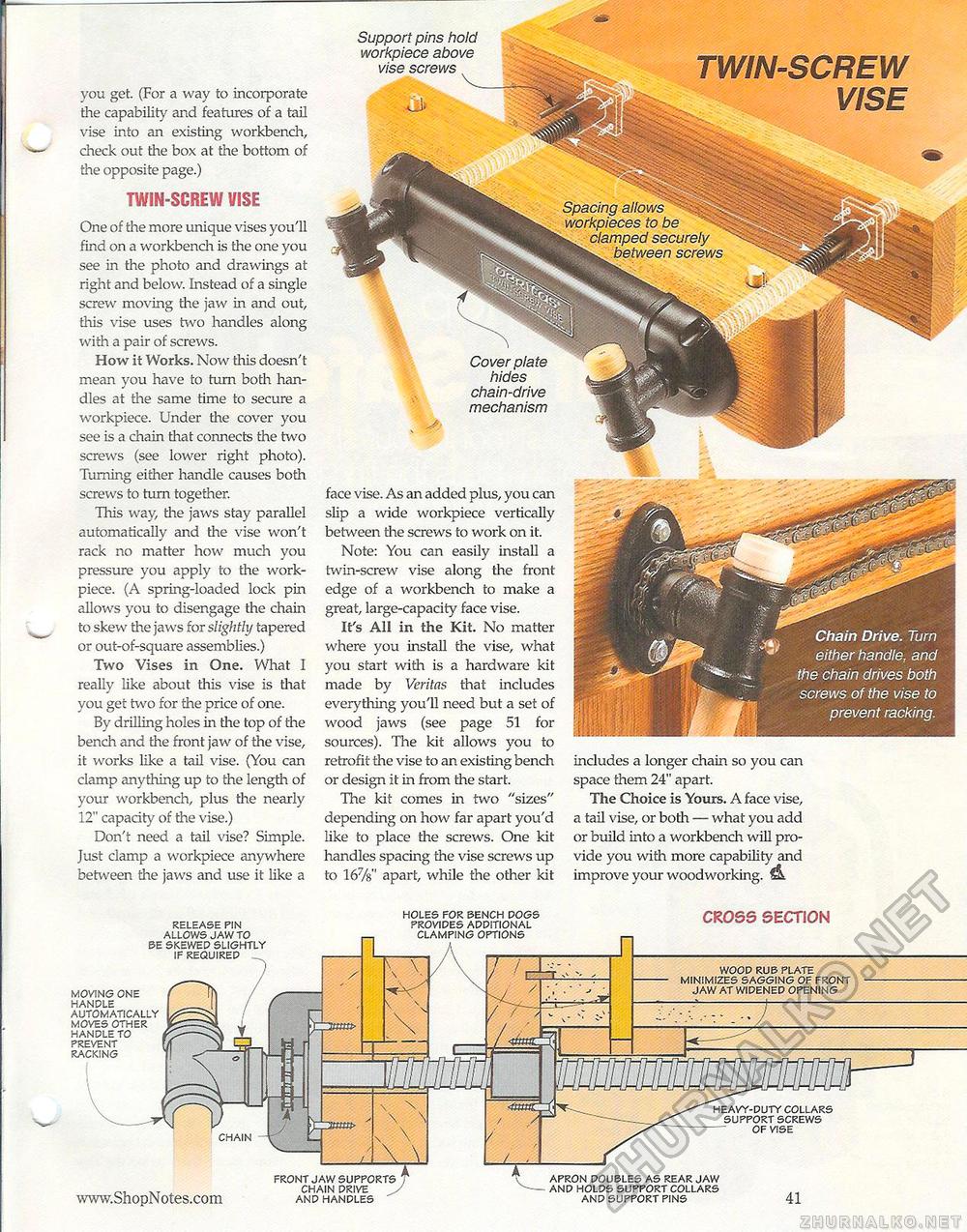

you get. (For a way to incorporate the capability and features of a tail vise into an existing workbench, check out the box at the bottom of the opposite page.) TWIN-SCREW VISE One of the more unique vises you'll find on a workbench is the one you see in the photo and drawings at right and below. Instead of a single screw moving the jaw in and out, this vise uses two handles along with a pair of screws. How it Works. Now this doesn't mean you have to turn both handles at the same time to secure a workpiece. Under the cover you see is a chain that connects the two screws (see lower right photo). Turning either handle causes both screws to turn together. This way, the jaws stay parallel automatically and the vise won't rack no matter how much you pressure you apply to the work-piece. (A spring-loaded lock pin allows you to disengage the chain to skew the jaws for slightly tapered or out-of-square assemblies.) Two Vises in One. What I really like about this vise is that you get two for the price of one. By drilling holes in the top of the bench and the front jaw of the vise, it works like a tail vise. (You can clamp anything up to the length of your workbench, plus the nearly 12" capacity of the vise.) Don't need a tail vise? Simple. Just clamp a workpiece anywhere between the jaws and use it like a Spacing allows •;.•/ workpieces to be ' " clamped securely low between screws Chain Drive. Turn either handle, and the chain drives both screws of the vise to prevent racking. TWIN-SCREW VISE Support pins hold workpiece above vise screws V face vise. As an added plus, you can slip a wide workpiece vertically between the screws to work on it. Note: You can easily install a twin-screw vise along the front edge of a workbench to make a great, large-capacity face vise. It's All in the Kit. No matter where you install the vise, what you start with is a hardware kit made by Veritas that includes everything you'll need but a set of wood jaws (see page 51 for sources). The kit allows you to retrofit the vise to an existing bench or design it in from the start. The kit comes in two "sizes" depending on how far apart you'd like to place the screws. One kit handles spacing the vise screws up to 16%" apart, while the other kit Cover plate hides chain-drive mechanism includes a longer chain so you can space them 24" apart. The Choice is Yours. A face vise, a tail vise, or both — what you add or build into a workbench will provide you with more capability and improve your woodworking. RELEASE PIN ALLOWS JAW TO BE SKEWED SLIGHTLY IF REQUIRED HOLES FOR BENCH DOGS PROVIDES ADDITIONAL ri AKApiKt/z nc-rmMe MOVING ONE HANDLE AUTOMATICALLY MOVES OTHER HANDLE TO PREVENT RACKING CHAIN FRONT JAW SUPPORTS CHAIN DRIVE V AND HANDLES CROSS SECTION WOOD RUB PLATE MINIMIZES SAGGING OF FRONT JAW AT WIDENED OPENING HEAVY-DUTY COLLARS SUPPORT SCREWS OF VISE APRON DOUBLES AS REAR JAW AND HOLDS SUPPORT COLLARS AND SUPPORT PINS 41 |