85 - Router Table, страница 33

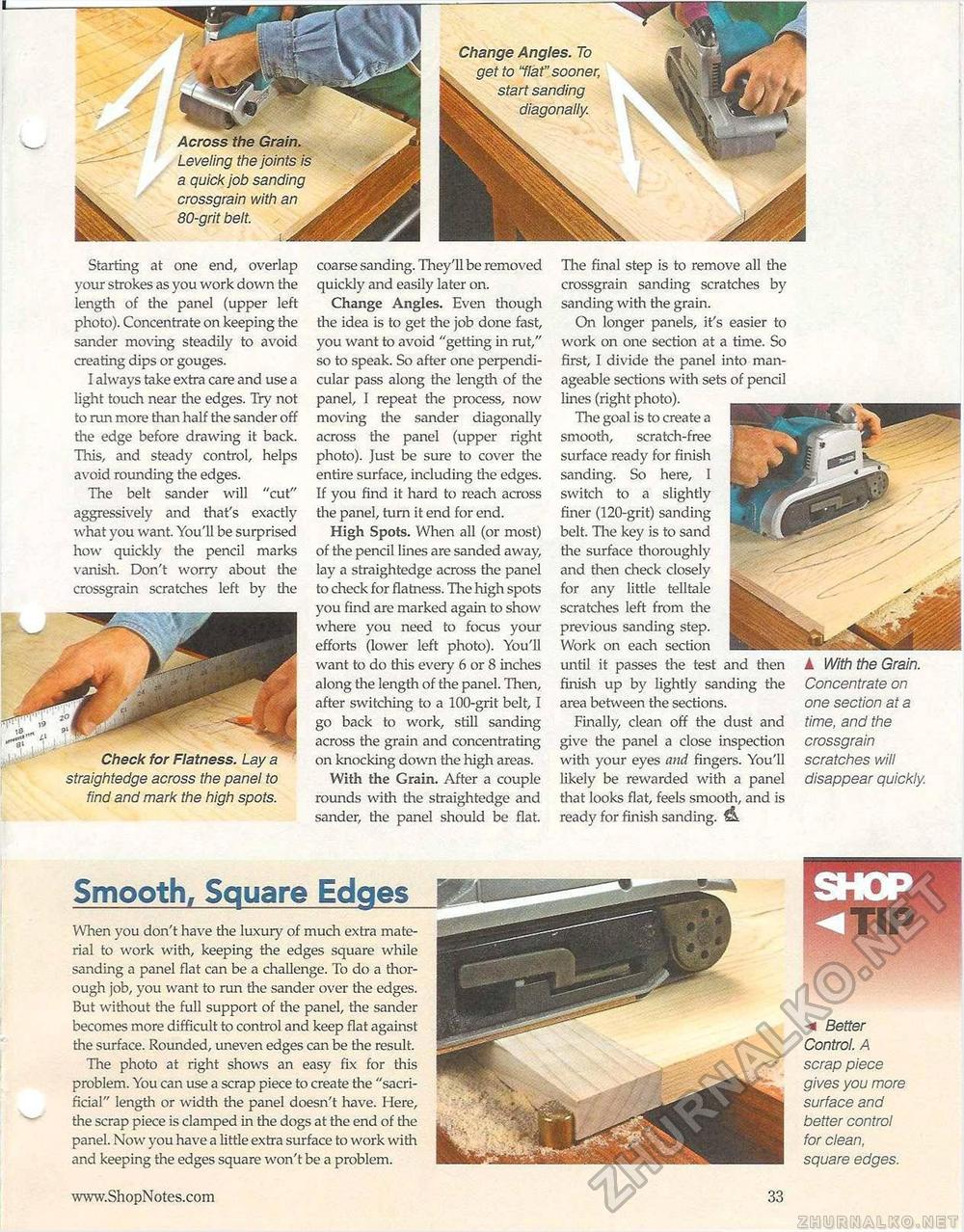

coarse sanding. They'll be removed quickly and easily later on. Change Angles. Even though the idea is to get the job done fast, you want to avoid "getting in rut," so to speak. So after one perpendicular pass along the length of the panel, I repeat the process, now moving the sander diagonally across the panel (upper right photo). Just be sure to cover the entire surface, including the edges. If you find it hard to reach across the panel, turn it end for end. High Spots. When all (or most) of the pencil lines are sanded away, lay a straightedge across the panel to check for flatness. Hie high spots you find are marked again to show where you need to focus your efforts (lower left photo). You'll want to do this every 6 or 8 inches along the length of the panel. Then, after switching to a 100-grit belt, I go back to work, still sanding across the grain and concentrating on knocking down the high areas. With the Grain. After a couple rounds with the straightedge and sander, the panel should be flat. Hie final step is to remove all the crossgrain sanding scratches by sanding with the grain. On longer panels, it's easier to work on one section at a time. So first, I divide the panel into manageable sections with sets of pencil lines (right photo). The goal is to create a smooth, scratch-free surface ready for finish sanding. So here, I switch to a slightly finer (120-grit) sanding belt. The key is to sand the surface thoroughly and then check closely for any little telltale scratches left from the previous sanding step. Work on each section ▲ With the Grain. Concentrate on one section at a time, and the crossgrain scratches will disappear quickly. until it passes the test and then finish up by lightly sanding the area between the sections. Finally, clean off the dust and give the panel a close inspection with your eyes and fingers. You'll likely be rewarded with a panel that looks flat, feels smooth, and is ready for finish sanding. Across the Grain. Leveling the joints is a quick job sanding crossgrain with an 80-grit belt. Starting at one end, overlap your strokes as you work down the length of the panel (upper left photo). Concentrate on keeping the sander moving steadily to avoid creating dips or gouges. I always take extra care and use a light touch near the edges. Try not to run more than half the sander off the edge before drawing it back. This, and steady control, helps avoid rounding the edges. The belt sander will "cut" aggressively and that's exactly what you want. You'll be surprised how quickly the pencil marks vanish. Don't worry about the crossgrain scratches left by the Check for Flatness. Lay a straightedge across the panel to find and mark the high spots. Smooth, Square Edges When you don't have the luxury of much extra material to work with, keeping the edges square while sanding a panel flat can be a challenge. To do a thorough job, you want to run the sander over the edges. But without the full support of the panel, the sander becomes more difficult to control and keep flat against the surface. Rounded, uneven edges can be the result. The photo at right shows an easy fix for this problem. You can use a scrap piece to create the "sacrificial" length or width the panel doesn't have. Here, the scrap piece is clamped in the dogs at the end of the panel. Now you have a little extra surface to work with and keeping the edges square won't be a problem. < Better Control. A scrap piece gives you more surface and better control for clean, square edges. 33 |