88, страница 3

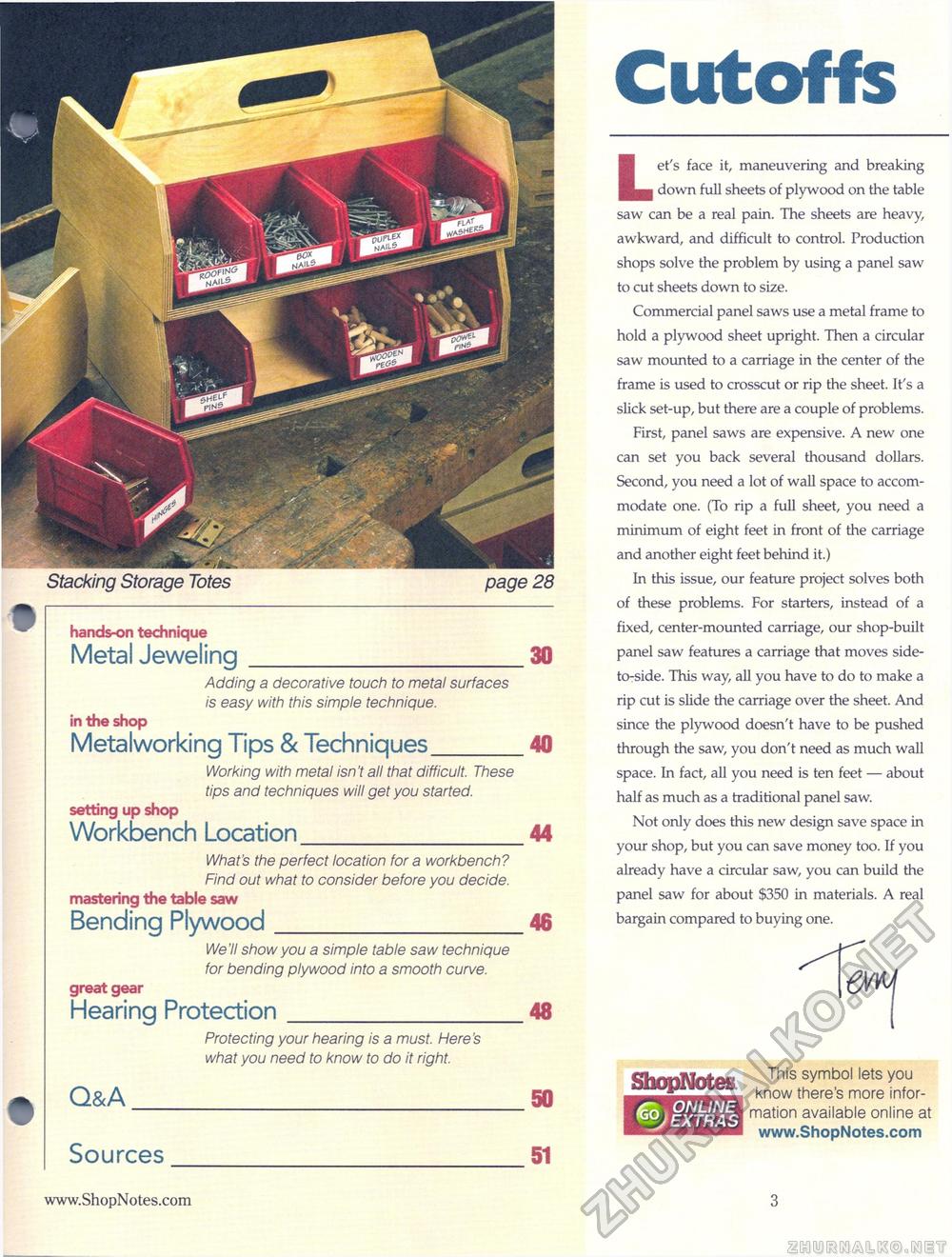

Stacking Storage Totes Cutoffs hands-on technique Metal Jeweling 30 Adding a decorative touch to metal surfaces is easy with this simple technique. in the shop Metal working Tips & Techniques_40 Working with metal isn't all that difficult. These tips and techniques will get you started. setting up shop Workbench Location What's the perfect location for a workbench? Find out what to consider before you decide. mastering the table saw Bending Plywood We'll show you a simple table saw technique for bending plywood into a smooth curve. great gear Hearing Protection_ Protecting your hearing is a must. Here's what you need to know to do it right. Q&A Sources 44 46 48 50 51 Let's face it, maneuvering and breaking down full sheets of plywood on the table saw can be a real pain. The sheets are heavy, awkward, and difficult to control. Production shops solve the problem by using a panel saw to cut sheets down to size. Commercial panel saws use a metal frame to hold a plywood sheet upright. Then a circular saw mounted to a carriage in the center of the frame is used to crosscut or rip the sheet. It's a slick set-up, but there are a couple of problems. First, panel saws are expensive. A new one can set you back several thousand dollars. Second, you need a lot of wall space to accommodate one. (To rip a full sheet, you need a minimum of eight feet in front of the carriage and another eight feet behind it.) In this issue, our feature project solves both of these problems. For starters, instead of a fixed, center-mounted carriage, our shop-built panel saw features a carriage that moves side-to-side. This way, all you have to do to make a rip cut is slide the carriage over the sheet. And since the plywood doesn't have to be pushed through the saw, you don't need as much wall space. In fact, all you need is ten feet — about half as much as a traditional panel saw. Not only does this new design save space in your shop, but you can save money too. If you already have a circular saw, you can build the panel saw for about $350 in materials. A real bargain compared to buying one. ShopN6te& ONLINE ^J EXTRAS This symbol lets you know there's more information available online at www.ShopNotes.com 3 |