88, страница 50

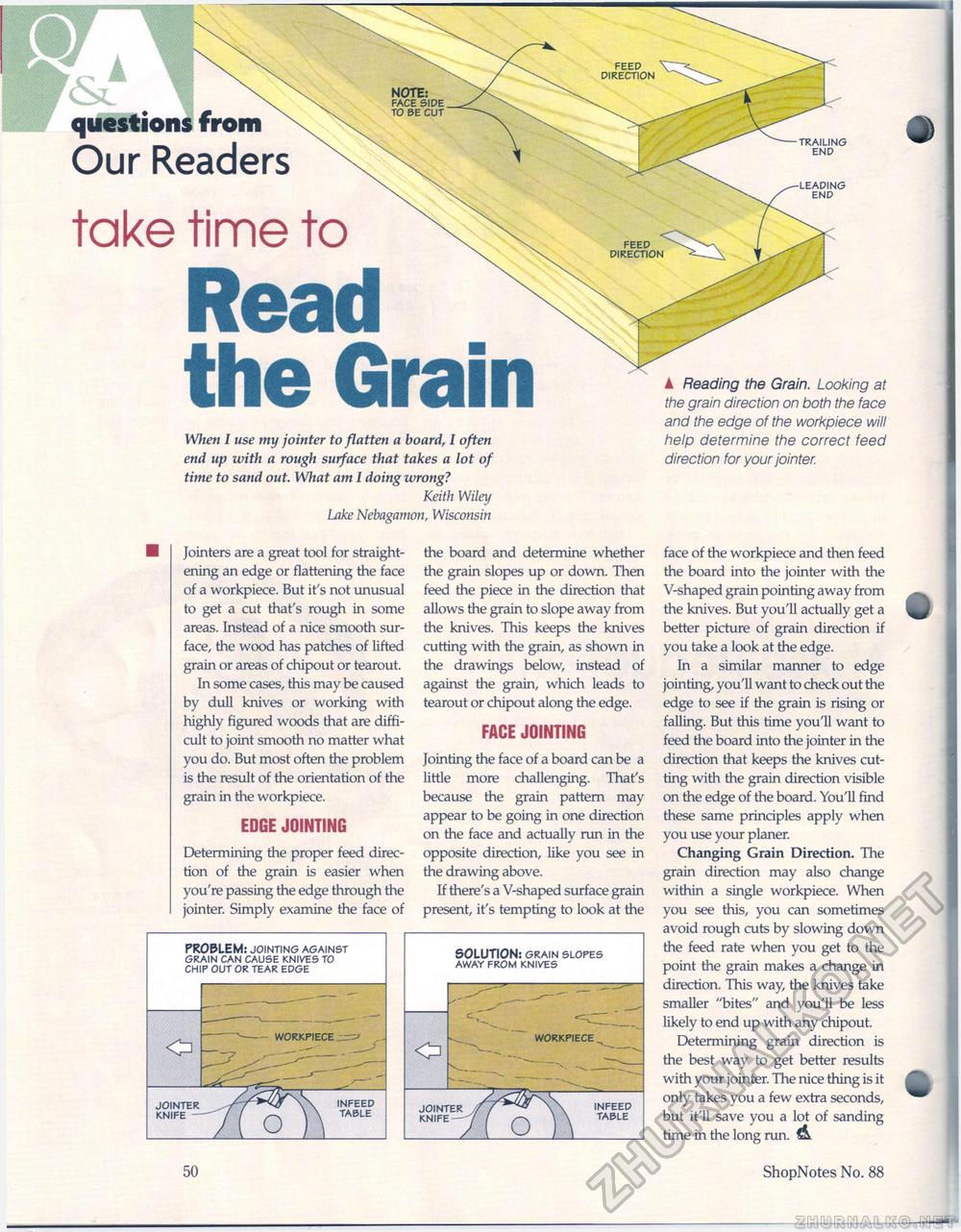

Our Readers take time to Read^H the Grain When I use my jointer to flatten a board, I often end up with a rough surface that takes a lot of time to sand out What am I doing wrong? Keith Wiley Lake Nebagamon, Wisconsin ▲ Reading the Grain. Looking at the grain direction on both the face and the edge of the workpiece will help determine the correct feed direction for your jointer. trailing end Jointers are a great tool for straightening an edge or flattening the face of a workpiece. But it's not unusual to get a cut that's rough in some areas. Instead of a nice smooth surface, the wood has patches of lifted grain or areas of chipout or tearout. In some cases, this may be caused by dull knives or working with highly figured woods that are difficult to joint smooth no matter what you do. But most often the problem is the result of the orientation of the grain in the workpiece. EDGE JOINTING Determining the proper feed direction of the grain is easier when you're passing the edge through the jointer. Simply examine the face of PROBLEM: jointing against grain can cause knives to chip out or tear edge the board and determine whether the grain slopes up or down. Then feed the piece in the direction that allows the grain to slope away from the knives. This keeps the knives cutting with the grain, as shown in the drawings below, instead of against the grain, which leads to tearout or chipout along the edge. FACE JOINTING Jointing the face of a board can be a little more challenging. That's because the grain pattern may appear to be going in one direction on the face and actually run in the opposite direction, like you see in the drawing above. If there's a V-shaped surface grain present, it's tempting to look at the

face of the workpiece and then feed the board into the jointer with the V-shaped grain pointing away from the knives. But you'll actually get a better picture of grain direction if you take a look at the edge. In a similar manner to edge jointing, you'll want to check out the edge to see if the grain is rising or falling. But this time you'll want to feed the board into the jointer in the direction that keeps the knives cutting with the grain direction visible on the edge of the board. You'll find these same principles apply when you use your planer. Changing Grain Direction. The grain direction may also change within a single workpiece. When you see this, you can sometimes avoid rough cuts by slowing down the feed rate when you get to the point the grain makes a change in direction. This way, the knives take smaller "bites" and you'll be less likely to end up with any chipout. Determining grain direction is the best way to get better results with your jointer. The nice thing is it only takes you a few extra seconds, but it'll save you a lot of sanding time in the long run. 50 ShopNotes No. 88 |

||||||||||