90 - Get the Most out of a Plunge Router, страница 30

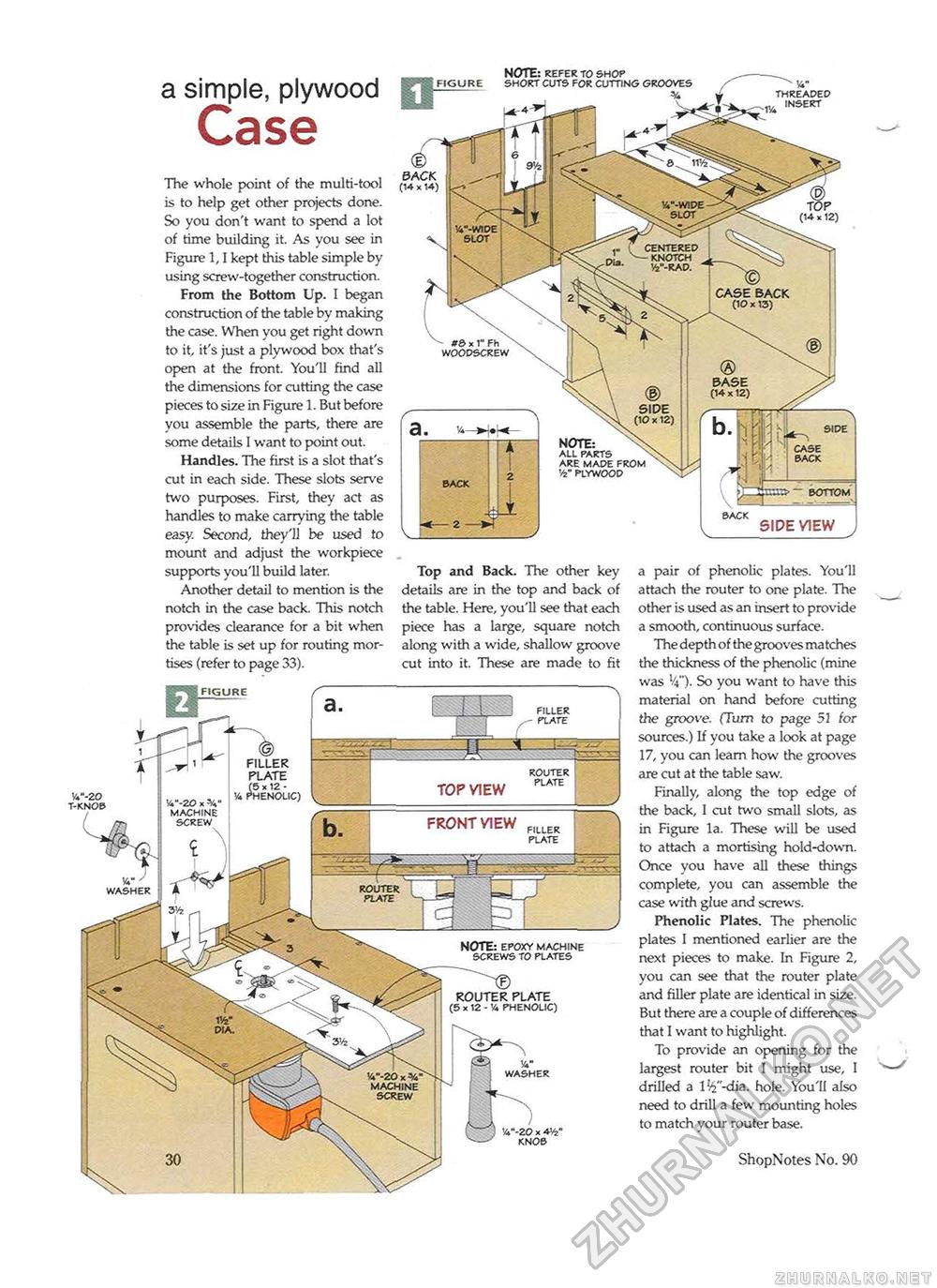

back a simple, plywood CaseBACK (14 x 14) (14 x 12) WASHER FIGURE 14" THREADED INSERT The whole point of the multi-tool is to help get other projects done. So you don't want to spend a lot of time building it. As you see in Figure 1 kept this table simple by using screw-together construction. From the Bottom Up. I began construction of the table by making the case. When you get right down to it it's just a plywood box that's open at the front. You'll find all the dimensions for cutting the case pieces to size in Figure 1. But before you assemble the parts, there are some details 1 want to point out. Handles. The first is a slot that's cut in each side. These slots serve two purposes. First, they act as handles to make carrying the table easy. Second, they'll be used to mount and adjust the workpiece supports you'll build later. Another detail to mention is the notch in the case back. This notch provides clearance for a bit when the table is set up for routing mortises (refer to page 33). v. "-20 T-KNOB NOTE: REFER TO SHOP SHORT CUTS FOR CUTTING GROOVES NOTE: ALL PARTS ARE MADE FROM V PLYWOOD BACK — BOTTOM BACK v SIDE VIEW a pair of phenolic plates. You'll attach the router to one plate. The other is used as an insert to provide a smooth, continuous surface. The depth of the grooves ma tches the thickness of the phenolic (mine was l/4"). So you want to have this material on hand before cutting the groove (Turn to page 52 for sources.) If you take a look at page 17, you can learn how the grooves are cut at the table saw. Finally, along the top edge of the back, I cut two small slots, as in Figure la. These will be used to attach a mortising hold-down. Once you have all these things complete, you can assemble the case with glue and screws. Phenolic Plates. The phenolic plates I mentioned earlier are the next pieces to make. In Figure 2, you can see that the router plate and filler plate are identical in size. But there are a couple of differences that I want to highlight. To provide an opening for the largest router bit I might use, I drilled a l^"-dia. hole. You'll also need to drill a few mounting holes to match your router base. ShopNotes No. 90 %"-2O x MACHINE SCREW TOP VIEW ROUTER PLATE FRONT VIEW FILLER PLATE FILLER PLATE (5 x 12 -Y. PHENOLIC) Top and Back. The other key details are in the top and back of the table. Here, you'll see that each piece has a large, square notch along with a wide, shallow groove cut into it. These are made to fit FILLER PLATE NOTE: EPOXY MACHINE SCREWS TO PLATES ROUTER PLATE (5 x 12 - 14 PHENOLIC) f3>, v WASHER 'A"-2O ---' KN 20 x 4V2" KNOB |