90 - Get the Most out of a Plunge Router, страница 6

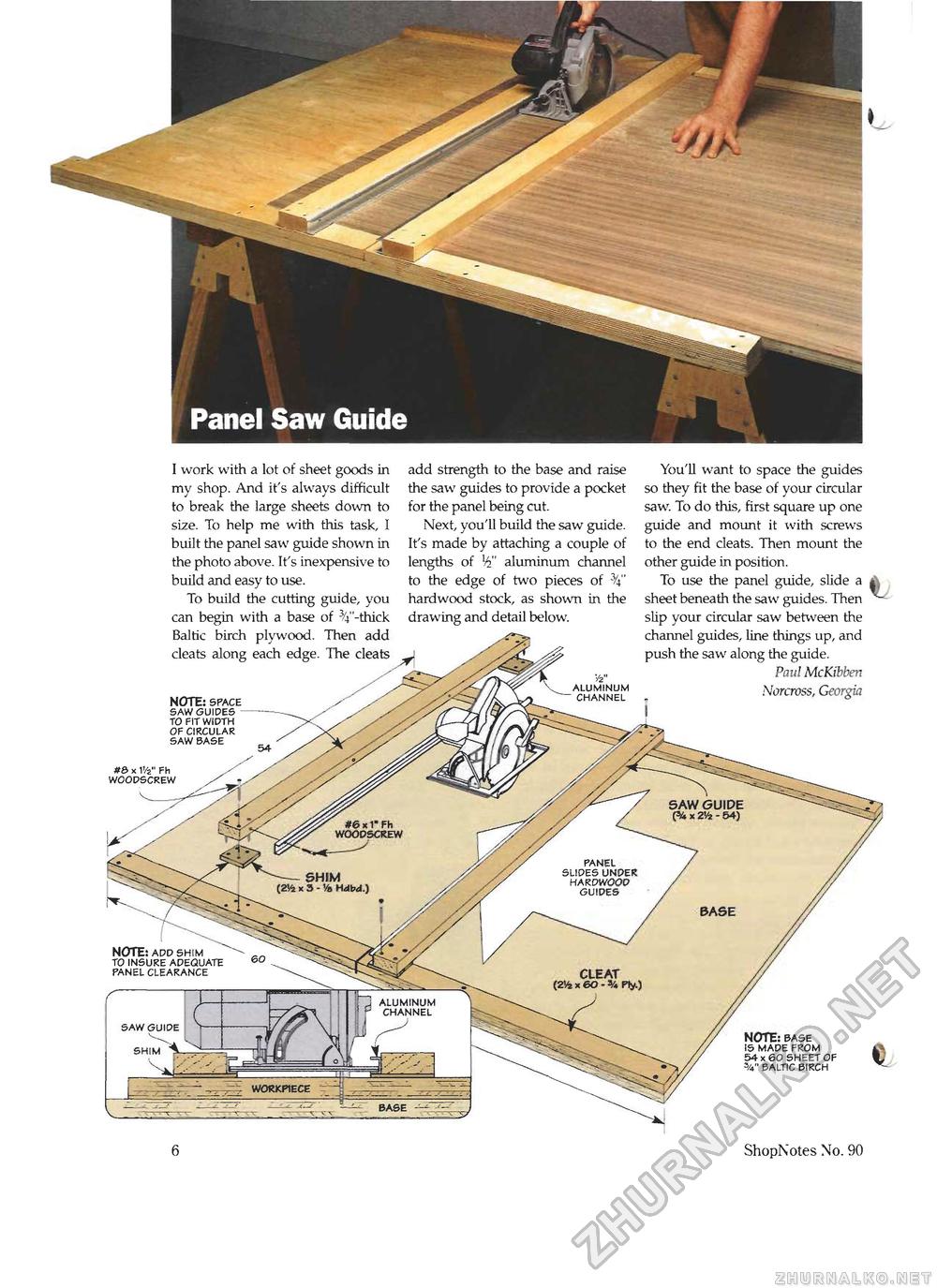

Panel Saw Guide SAW GUIDE pi x 2V2 - 54) #6 x 1" Fh WOODSCREW PANEL SLIDES UNDER HARDWOOD GUIDES -— SHIM (2V4 x 3 - tfe Hdbd.) WORKP1ECE I work with a lot of sheet goods in my shop. And it's always difficult to break the large sheets down to size. To help me with this task, I built the panel saw guide shown in the photo above. It's inexpensive to build and easy to use. To build the cutting guide, you can begin with a base of 34"-thick Baltic birch plywood. Then add cleats along each edge. The cleats NOTE: space saw guides to fit width of circular saw base add strength to the base and raise the saw guides to provide a pocket for the panel being cut. Next, you'll build the saw guide. It's made by attaching a couple of lengths of Vi' aluminum channel to the edge of two pieces of hardwood stock, as shown in the drawing and detail below. You'll want to space the guides so they fit the base of your circular saw. To do this, first square up one guide and mount it with screws to the end cleats. Then mount the other guide in position. To use the panel guide, slide a sheet beneath the saw guides. Then slip your circular saw between the channel guides, line things up, and push the saw along the guide. PaulMcKibben Norcross, Georgia #S x I'/z" FH WOODSCREW /z aluminum channel NOTE: ADD SHIM TO INSURE ADEQUATE PANEL CLEARANCE j ALUMINUM - CHANNEL SAW GUIDE SHIM BASE — NOTE: base IS MADE FROM 54 x 60 SHEET OF 3/4n BALTIC BIRCH 6 ShopNotes No. 90 |