Woodworker's Journal 101-Projects-for-Woodworkers, страница 21

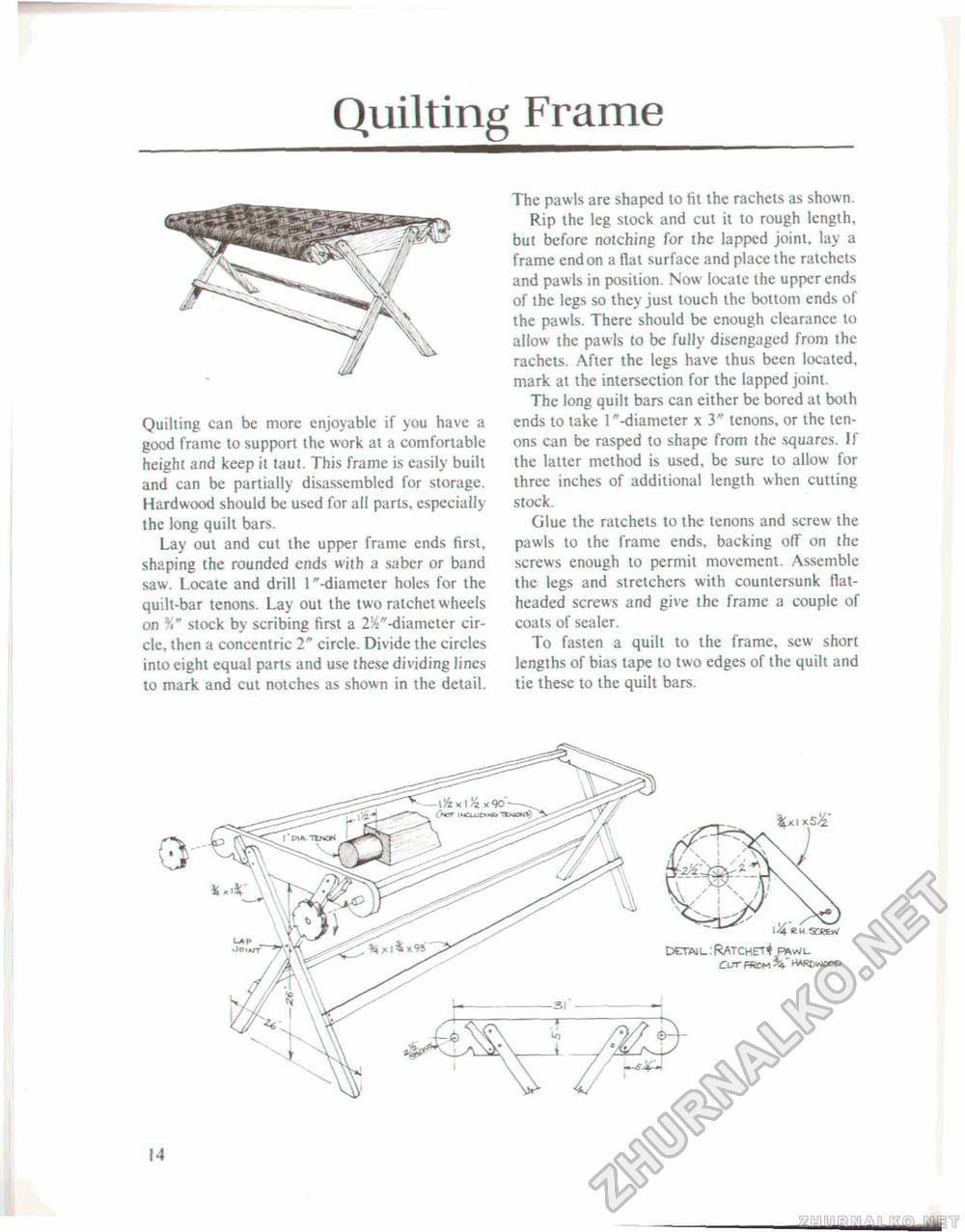

Quilting FrameThe pawls are shaped to fit the rachets as shown. Rip the leg stock and cut it to rough length, but before notching for the lapped joint, lay a frame end on a flat surface and place the ratchets and pawls in position. Now locate the upper ends of the legs so they just touch the bottom ends of the pawls. There should be enough clearance to allow the pawls to be fully disengaged from the rachets. After the legs have thus been located, mark at the intersection for the lapped joint. The long quilt bars can either be bored at both ends to take I "-diameter x 3" tenons, or the tenons can be rasped to shape from the squares. If the latter method is used, be sure to allow for three inches of additional length when cutting stock. Glue the ratchets to the tenons and screw the pawls to the frame ends, backing off on the screws enough to permit movement. Assemble the legs and stretchers with countersunk flat-headed screws and give the frame a couple of coats of sealer. To fasten a quilt to the frame, sew short lengths of bias tape to two edges of the quill and tie these to the quilt bars. 14 Quilting can be more enjoyable if you have a good frame to support the work at a comfortable height and keep it taut. This frame is easily built and can be partially disassembled for storage. Hardwood should be used for all parts, especially the long quilt bars. Lay out and cul the upper frame ends first, shaping the rounded ends with a saber or band saw. Locale and drill 1 "-diameter holes for the quilt-bar tenons. Lay out the two ratchet wheels on Vt" stock by scribing first a 2^"-diamcter circle. then a concentric 2" circle. Divide the circles into eight equal pans and use these dividing lines to mark and cut notches as shown in the detail. |