Woodworker's Journal 101-Projects-for-Woodworkers, страница 248

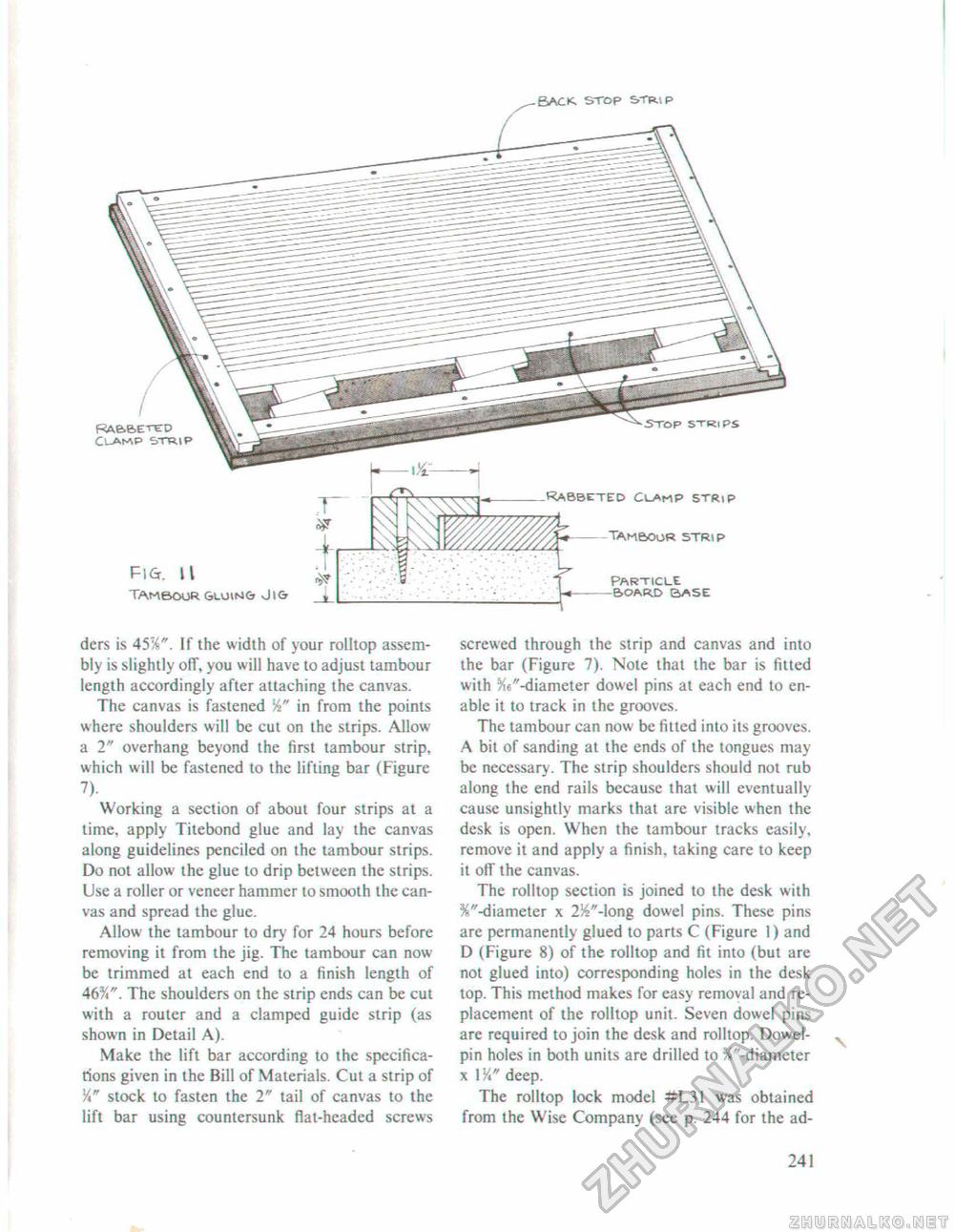

11 Tambour &UJIN& Jt& ders is 45%". If the width of your rolltop assembly is slightly off, you will have to adjust tambour length accordingly after attaching the canvas. The canvas is fastened in from the points where shoulders will be cut on the strips. Allow a 2" overhang beyond the first tambour strip, which will be fastened to the lifting bar (Figure 7). Working a section of about four strips at a time, apply Titebond glue and lay the canvas along guidelines penciled on the tambour strips. Do not allow the glue to drip between the strips. Use a roller or veneer hammer to smooth the canvas and spread the glue. Allow the tambour to dry for 24 hours before removing it from the jig. The tambour can now be trimmed at each end to a finish length of 46%". The shoulders on the strip ends can be cut with a router and a clamped guide strip (as shown in Detail A). Make the lift bar according to the specifications given in the Bill of Materials. Cut a strip of Va" stock to fasten the 2" tail of canvas to the lift bar using countersunk flat-headed screws screwed through the strip and canvas and into the bar (Figure 7). Note that the bar is fitted with ^"-diameter dowel pins at each end to enable it to track in the grooves. The tambour can now be fitted into its grooves. A bit of sanding at the ends of the tongues may be necessary. The strip shoulders should not rub along the end rails because that will eventually cause unsightly marks that are visible when the desk is open. When the tambour tracks easily, remove it and apply a finish, taking care to keep it off the canvas. The rolltop section is joined to the desk with ^"-diameter x 254"-long dowel pins. These pins are permanently glued to parts C (Figure 1) and D (Figure 8) of the rolltop and fit into (but are not glued into) corresponding holes in the desk top. This method makes for easy removal and replacement of the rolltop unit. Seven dowel pins are required to join the desk and rolltop. Dowel-pin holes in both units are drilled to ^"-diameter x IK" deep. The rolltop lock model +tL31 was obtained from the Wise Company (see p. 244 for the ad 241 |