Woodworker's Journal 1981-5-6, страница 38

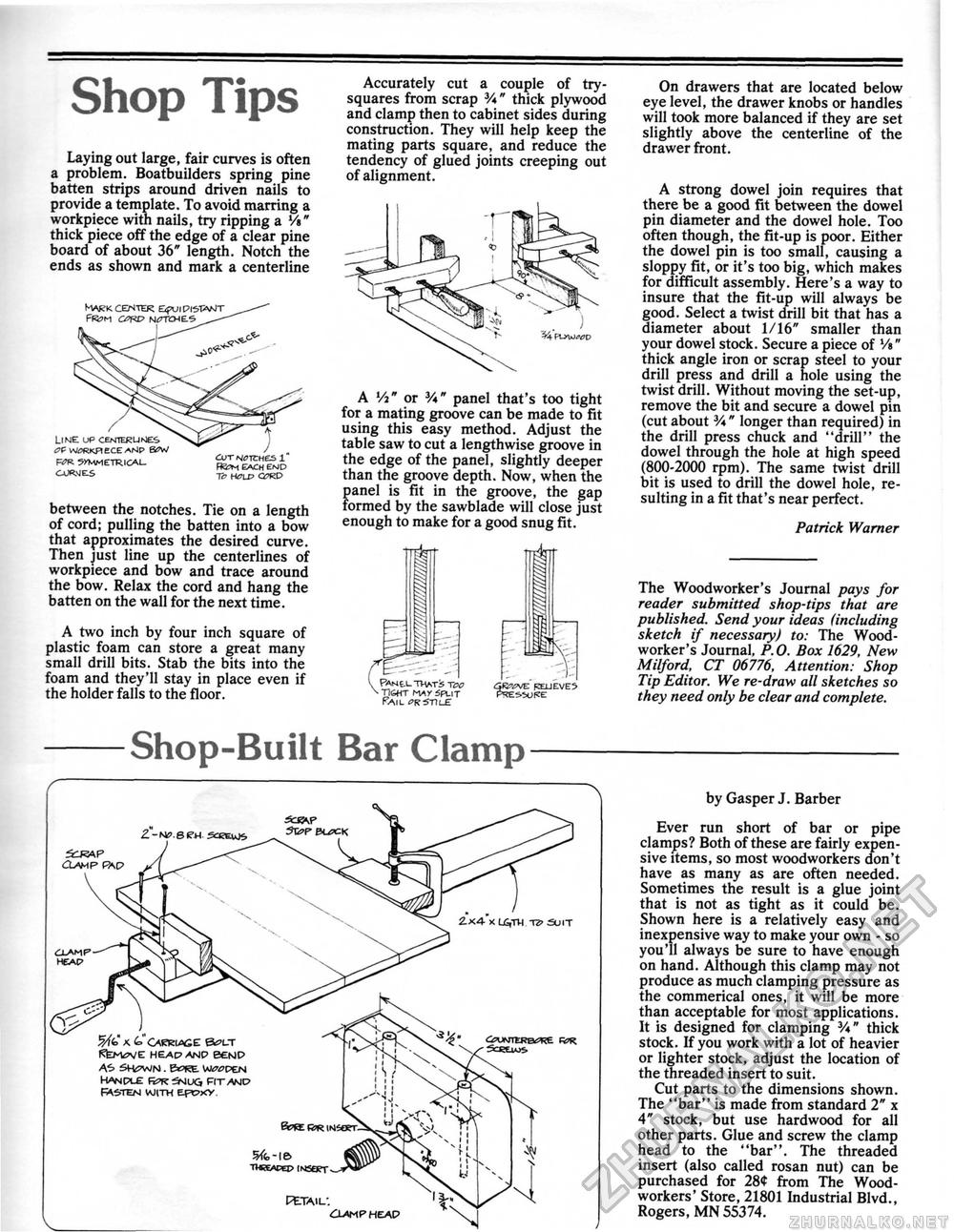

Shop Tips Laying out large, fair curves is often a problem. Boatbuilders spring pine batten strips around driven nails to provide a template. To avoid marring a workpiece with nails, try ripping a '/«" thick piece off the edge of a clear pine board of about 36" length. Notch the ends as shown and mark a centerline between the notches. Tie on a length of cord; pulling the batten into a bow that approximates the desired curve. Then just line up the centerlines of workpiece and bow and trace around the bow. Relax the cord and hang the batten on the wall for the next time. A two inch by four inch square of plastic foam can store a great many small drill bits. Stab the bits into the foam and they'll stay in place even if the holder falls to the floor. Accurately cut a couple of try-squares from scrap V*" thick plywood and clamp then to cabinet sides during construction. They will help keep the mating parts square, and reduce the tendency of glued joints creeping out of alignment. A Vi" or V*" panel that's too tight for a mating groove can be made to fit using this easy method. Adjust the table saw to cut a lengthwise groove in the edge of the panel, slightly deeper than the groove depth. Now, when the panel is fit in the groove, the gap formed by the sawblade will close just enough to make for a good snug fit. V PANELTHM-i T0C ^ Tight M*y 5PUIT Fail okSTilE On drawers that are located below eye level, the drawer knobs or handles will took more balanced if they are set slightly above the centerline of the drawer front. A strong dowel join requires that there be a good fit between the dowel pin diameter and the dowel hole. Too often though, the fit-up is poor. Either the dowel pin is too small, causing a sloppy fit, or it's too big, which makes for difficult assembly. Here's a way to insure that the fit-up will always be good. Select a twist drill bit that has a diameter about 1/16" smaller than your dowel stock. Secure a piece of V»" thick angle iron or scrap steel to your drill press and drill a hole using the twist drill. Without moving the set-up, remove the bit and secure a dowel pin (cut about V* " longer than required) in the drill press chuck and "drill" the dowel through the hole at high speed (800-2000 rpm). The same twist drill bit is used to drill the dowel hole, resulting in a fit that's near perfect. Patrick Warner <s©we peueve5 PSE5-SOPE The Woodworker's Journal pays for reader submitted shop-tips that are published. Send your ideas (including sketch if necessary) to: The Woodworker's Journal, P.O. Box 1629, New Milford, CT 06776, Attention: Shop Tip Editor. We re-draw all sketches so they need only be clear and complete. Shop-Built Bar Clamp by Gasper J. Barber Ever run short of bar or pipe clamps? Both of these are fairly expensive items, so most woodworkers don't have as many as are often needed. Sometimes the result is a glue joint that is not as tight as it could be. Shown here is a relatively easy and inexpensive way to make your own - so you'll always be sure to have enough on hand. Although this clamp may not produce as much clamping pressure as the commerical ones, it will be more than acceptable for most applications. It is designed for clamping 3A" thick stock. If you work with a lot of heavier or lighter stock, adjust the location of the threaded insert to suit. Cut parts to the dimensions shown. The "bar" is made from standard 2" x 4" stock, but use hardwood for all other parts. Glue and screw the clamp head to the "bar". The threaded insert (also called rosan nut) can be purchased for 28<t from The Woodworkers' Store, 21801 Industrial Blvd., Rogers, MN 55374. Mark center Line up centerune'S WCRKfieCE AMP B5W F^R SYMMETRICAL CURvlES CUT NOTCHES 1 ffem each end To WW C0&D 5/!i>' x Carriage heapanp bcmp as sh5"a/n . &ore w^pen hanple fi?k5nui fit and fasten with epp*y |