Woodworker's Journal 1982-6-5, страница 44

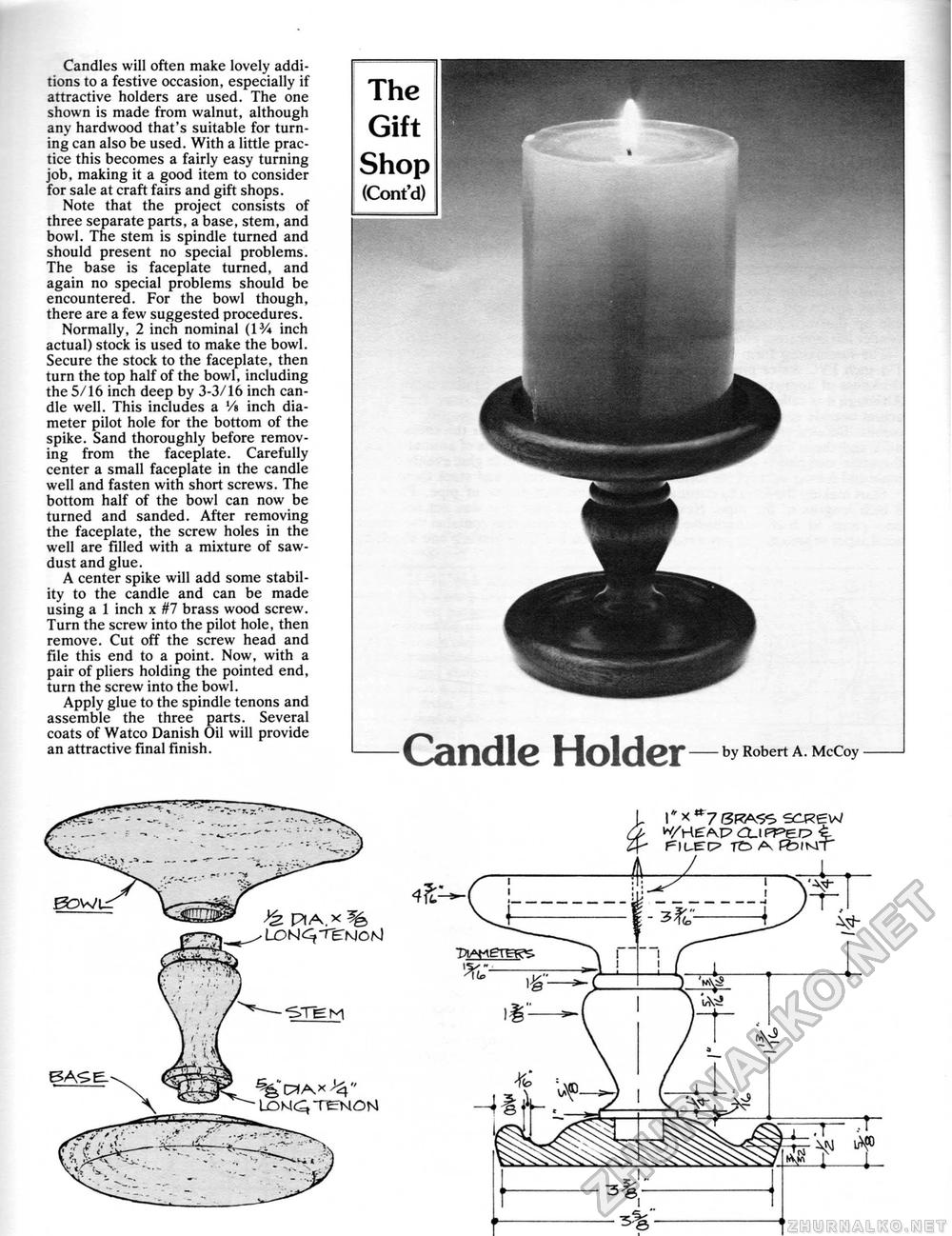

Candles will often make lovely additions to a festive occasion, especially if attractive holders are used. The one shown is made from walnut, although any hardwood that's suitable for turning can also be used. With a little practice this becomes a fairly easy turning job, making it a good item to consider for sale at craft fairs and gift shops. Note that the project consists of three separate parts, a base, stem, and bowl. The stem is spindle turned and should present no special problems. The base is faceplate turned, and again no special problems should be encountered. For the bowl though, there are a few suggested procedures. Normally, 2 inch nominal (1 Va inch actual) stock is used to make the bowl. Secure the stock to the faceplate, then turn the top half of the bowl, including the 5/16 inch deep by 3-3/16 inch candle well. This includes a Vi inch diameter pilot hole for the bottom of the spike. Sand thoroughly before removing from the faceplate. Carefully center a small faceplate in the candle well and fasten with short screws. The bottom half of the bowl can now be turned and sanded. After removing the faceplate, the screw holes in the well are filled with a mixture of sawdust and glue. A center spike will add some stability to the candle and can be made using a 1 inch x #7 brass wood screw. Turn the screw into the pilot hole, then remove. Cut off the screw head and file this end to a point. Now, with a pair of pliers holding the pointed end, turn the screw into the bowl. Apply glue to the spindle tenons and assemble the three parts. Several coats of Watco Danish Oil will provide an attractive final finish. —Candle Holder—byRobertAMcCoy The Gift Shop (Cont'd) |