Woodworker's Journal 1983-7-5, страница 65

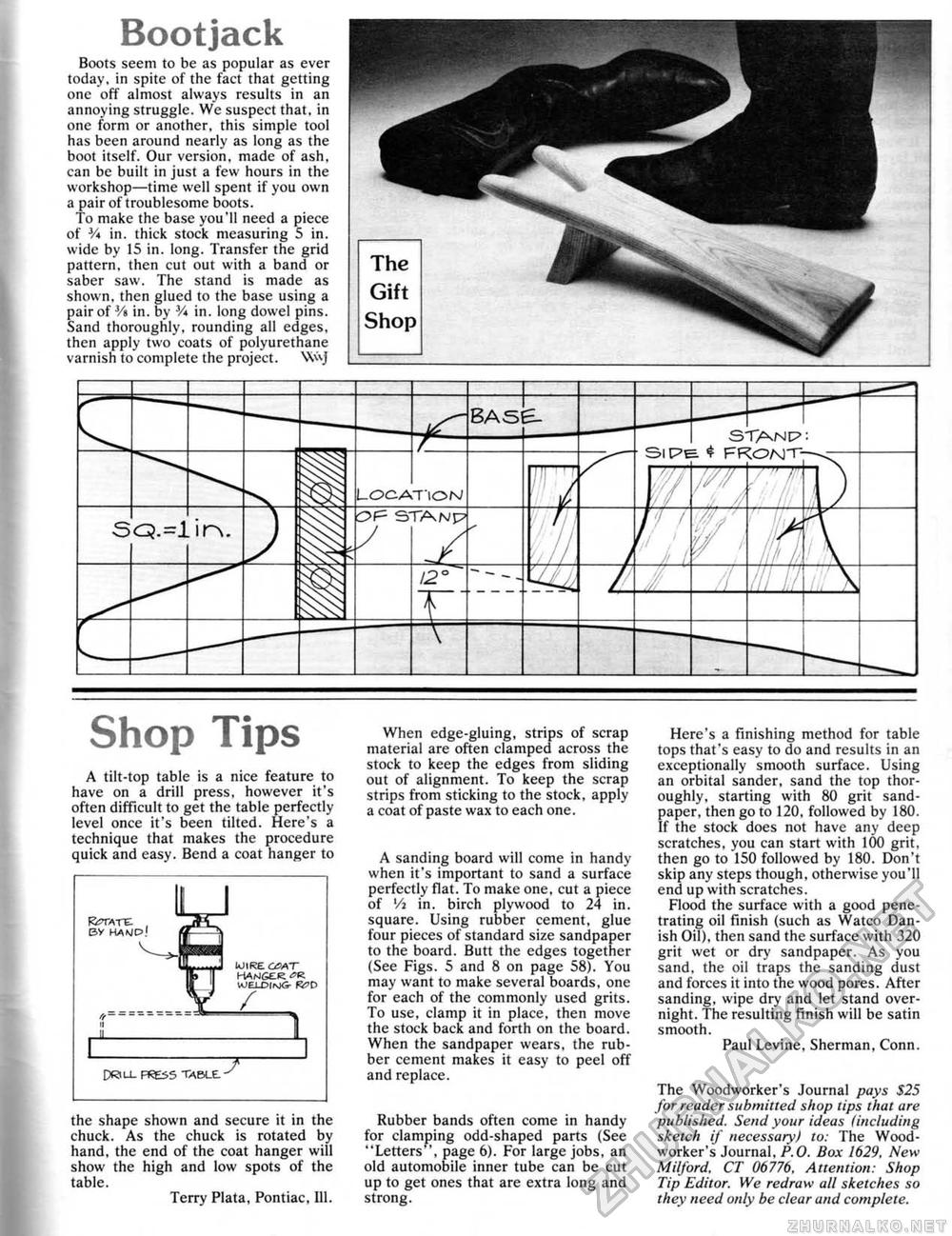

Bootjack Boots seem to be as popular as ever today, in spite of the fact that getting one off almost always results in an annoying struggle. We suspect that, in one form or another, this simple tool has been around nearly as long as the boot itself. Our version, made of ash, can be built in just a few hours in the workshop—time well spent if you own a pair of troublesome boots. To make the base you'll need a piece of V* in. thick stock measuring 5 in. wide by 15 in. long. Transfer the grid pattern, then cut out with a band or saber saw. The stand is made as shown, then glued to the base using a pair of 3/s in. by V* in. long dowel pins. Sand thoroughly, rounding all edges, then appiy two coats of polyurethane varnish to complete the project. W\J Shop Tips A tilt-top table is a nice feature to have on a drill press, however it's often difficult to get the table perfectly level once it's been tilted. Here's a technique that makes the procedure quick and easy. Bend a coat hanger to the shape shown and secure it in the chuck. As the chuck is rotated by hand, the end of the coat hanger will show the high and low spots of the table. Terry Plata, Pontiac, 111. When edge-gluing, strips of scrap material are often clamped across the stock to keep the edges from sliding out of alignment. To keep the scrap strips from sticking to the stock, apply a coat of paste wax to each one. A sanding board will come in handy when it's important to sand a surface perfectly flat. To make one, cut a piece of Vi in. birch plywood to 24 in. square. Using rubber cement, glue four pieces of standard size sandpaper to the board. Butt the edges together (See Figs. 5 and 8 on page 58). You may want to make several boards, one for each of the commonly used grits. To use, clamp it in place, then move the stock back and forth on the board. When the sandpaper wears, the rubber cement makes it easy to peel off and replace. Rubber bands often come in handy for clamping odd-shaped parts (See "Letters", page 6). For large jobs, an old automobile inner tube can be cut up to get ones that are extra long and strong. Here's a finishing method for table tops that's easy to do and results in an exceptionally smooth surface. Using an orbital sander, sand the top thoroughly, starting with 80 grit sandpaper, then go to 120, followed by 180. If the stock does not have any deep scratches, you can start with 100 grit, then go to"150 followed by 180. Don't skip any steps though, otherwise you'll end up with scratches. Flood the surface with a good penetrating oil finish (such as Watco Danish Oil), then sand the surface with 320 grit wet or dry sandpaper. As you sand, the oil traps the sanding dust and forces it into the wood pores. After sanding, wipe dry and let stand overnight. The resulting finish will be satin smooth. Paul Levine, Sherman, Conn, The Woodworker's Journal pays S25 for reader submitted shop tips that are published. Send your ideas (including sketch if necessary) to: The Woodworker's Journal, P.O. Box 1629, New Milford. CT 0677b, Attention: Shop Tip Editor. We redraw all sketches so they need only be clear and complete. |