Woodworker's Journal 1983-7-6, страница 18

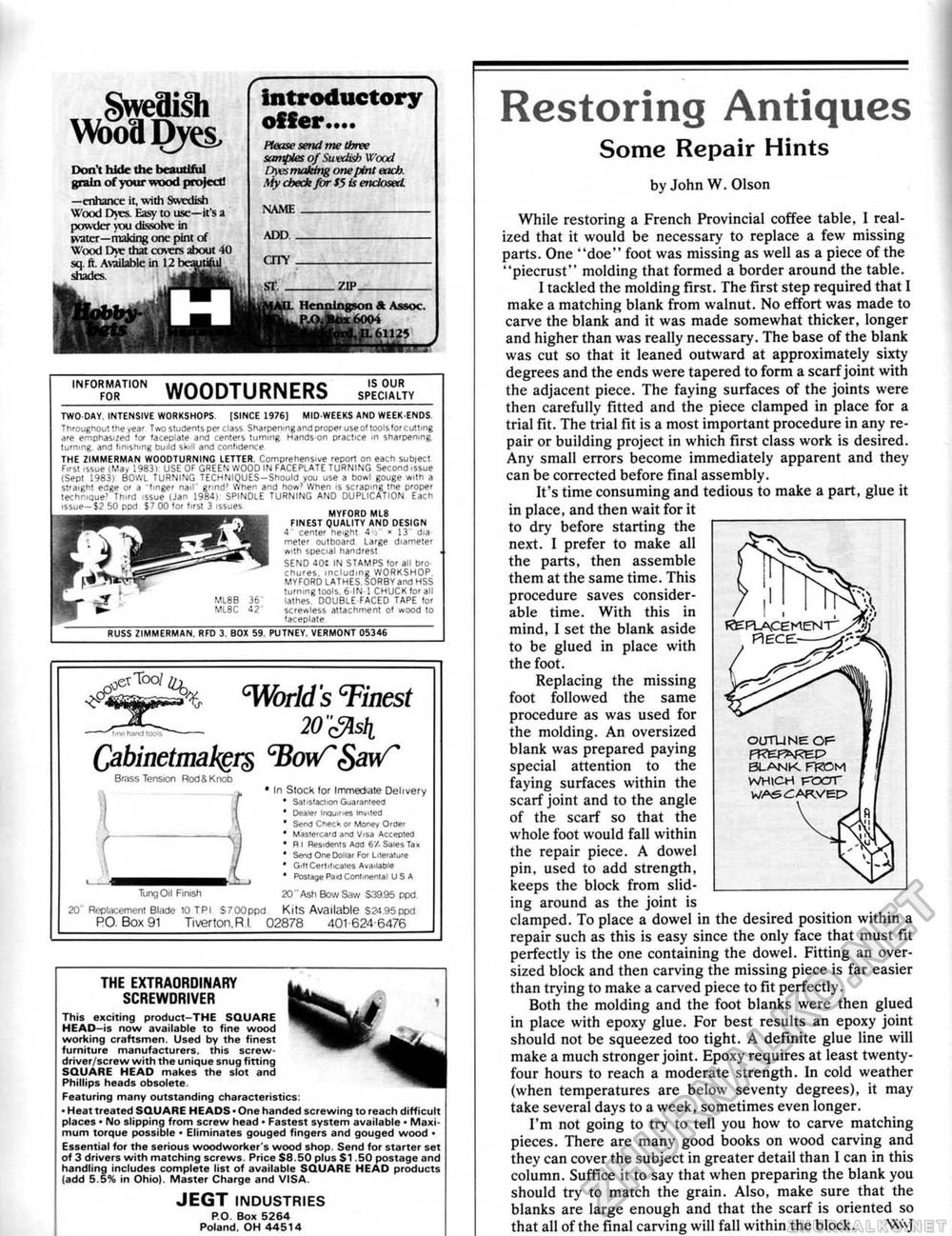

§wedish WooS Dyes, Don't hide the beautiful grain of your wood project! —enhance it, with Swrdish Wood Dyes. Easy lo use—it's a powder iou dissolve in fvzKr—making one pint of Wood Dye that rovers about 40 sq. ft. Available in 12" shades. Introductory offer.... Please send me three samples of Swedish Wood /Juts making one pint each. Aty check for S5 is enciosed NAME . INFORMATION FOR WOODTURNERS IS OUR SPECIALTY TWO DAY INTENSIVE WORKSHOPS (SINCE 1976) MID-WEEKS AND WEEK ENDS Throughout The r-.'A' Two students per class Sharpening and proper use of tmlsfur cutting are emphasised for faceplate and centers turnrng Hands on practice sharpening lurnrng and finishing puild skill and conlidence THE ZIMMERMAN WOOOTURNING LETTER. Comprehensive report on each suDiect First issue tMay 1983) USE OF GREEN WOOD IN FACEPLATE TURNING Second issue iSew 19831 BOWL TURNING TECHNiQUES-Snould you use a bowl gouge witfl a straigh! edge or d linger na>' ' grind* wnen and how3 V. r , scraping the proper technique' Tturd ssue iJan 198J1 SPINDlE TURNING AND DUPLICATION Each issue-i? 60 ppd |7 OOfor Iirsl 3 issues MYFORD MLB FINEST QUALITY AND DESIGN a center height J . * 13 dia meter ouiboard Large diameter with special handrest SEND 4D( IN STAMPS lor all Procures including WORKSHOP MYFORD LATHES. SORBVano HSS turning tOOIS. 6 IN 1 CHUCK for all lathes DOuBlE FACED TAPE lor scre*'ess attachment ot wood to faceplate RUSS ZIMMERMAN. RFD 3. BOX 59 PUTNEY. VERMONT 05346 jSZL&l World s "Finest 20'&sti Cabinetmakers ^ovf '■iv- haqd roo' Brass Tension Rod3 Knob Tung Oil Finish { 7 20 Replacement Blade to TP I S700ppd 1 In Stock for immediate Delivery • Satisfaction Guaranteed * Dealer Inquiries invited * Send Chech or Money OrGer • Mastercard and Visa Accepted • RJ Residents Atid 6/ Sates Tax * Send One Dollar Few Literature * Gift Cert if icaies Avanaoie • Postage Pad Contmenia* USA 20" Ash Bow Saw $3995 ppd Kits Available $2495ppd PO Box 91 Tiverton, R I, 02878 401624 6476 THE EXTRAORDINARY SCREWDRIVER v This exciting product-THE SQUARE HEAD-is now available to fine wood working craftsmen. Used try the finest furniture manufacturers, this screwdriver/screw with the unique snug fitting SQUARE HEAD makes the slot and Phillips heads obsolete Featuring many outstanding characteristics: ■Heat treated SQUARE HEADS - One handed screwing to reach difficult places • Mo slipping from screw head • Fastest system available • Maximum torque possible - Eliminates gouged fingers and gouged wood * Essentia) for the serious woodworker's wood shop. Send for starter set of 3 drivers with matching screws. Price $8.50 plus SI .50 postage and handling includes complete list of available SQUARE HEAD products (add 5.5% in Ohio). Master Charge and VISA. JEGT INDUSTRIES P.O Box 5264 Poland. OH 44514 Restoring AntiquesSome Repair Hintsby John W.Olson While restoring a French Provincial coffee table, I realized that it would be necessary to replace a few missing parts. One "doe" foot was missing as well as a piece of the "piecrust" molding that formed a border around the table. I tackled the molding first. The first step required that I make a matching blank from walnut. No effort was made to carve the blank and it was made somewhat thicker, longer and higher than was really necessary. The base of the blank was cut so that it leaned outward at approximately sixty degrees and the ends were tapered to form a scarf joint with the adjacent piece. The faying surfaces of the joints were then carefully fitted and the piece clamped in place for a trial fit. The trial fit is a most important procedure in any repair or building project in which first class work is desired. Any small errors become immediately apparent and they can be corrected before final assembly, It's time consuming and tedious to make a part, glue it in place, and then wait for it to dry before starting the next. I prefer to make all the parts, then assemble them at the same time. This procedure saves considerable time. With this in mind, I set the blank aside to be glued in place with the foot. Replacing the missing foot followed the same procedure as was used for the molding. An oversized blank was prepared paying special attention to the faying surfaces within the scarf joint and to the angle of the scarf so that the whole foot would fall within the repair piece. A dowel pin, used to add strength, keeps the block from sliding around as the joint is clamped. To place a dowel in the desired position within a repair such as this is easy since the only face that must fit perfectly is the one containing the dowel. Fitting an oversized block and then carving the missing piece is far easier than trying to make a carved piece to fit perfectly. Both the molding and the foot blanks were then glued in place with epoxy glue. For best results an epoxy joint should not be squeezed too tight. A definite glue line will make a much stronger joint. Epoxy requires at least twenty-four hours to reach a moderate strength. In cold weather (when temperatures are below seventy degrees), it may take several days to a week, sometimes even longer. I'm not going to try to tell you how to carve matching pieces. There are many good books on wood carving and they can cover the subject in greater detail than I can in this column. Suffice it to say that when preparing the blank you should try to match the grain. Also, make sure that the blanks are large enough and that the scarf is oriented so that all of the final carving will fall within the block. Wvj |