Woodworker's Journal 1984-8-4, страница 50

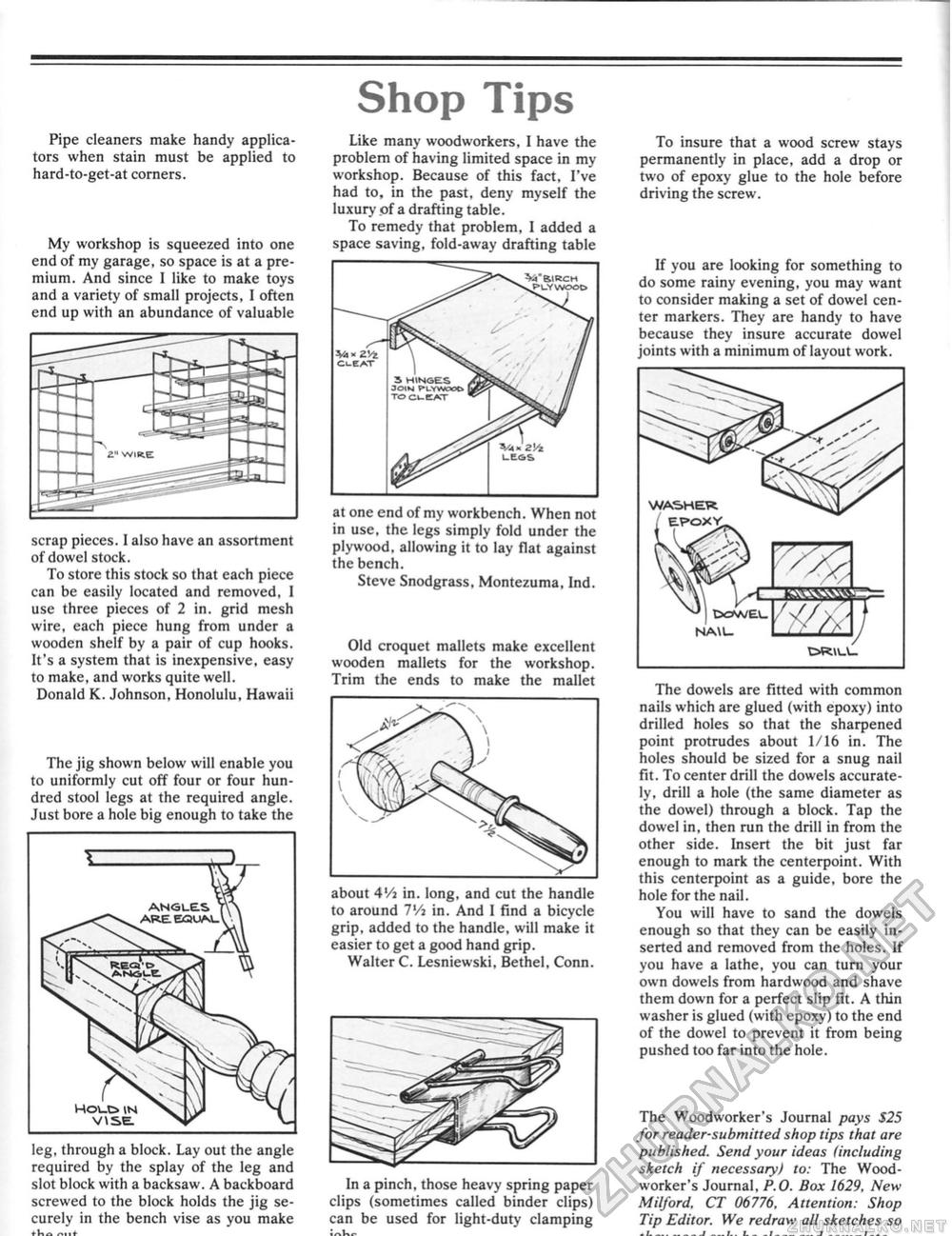

Shop Tips Pipe cleaners make handy applicators when stain must be applied to hard-to-get-at corners. My workshop is squeezed into one end of my garage, so space is at a premium. And since I like to make toys and a variety of small projects, I often end up with an abundance of valuable scrap pieces. 1 also have an assortment of dowel stock. To store this stock so that each piece can be easily located and removed. I use three pieces of 2 in. grid mesh wire, each piece hung from under a wooden shelf by a pair of cup hooks. It's a system that is inexpensive, easy to make, and works quite well. Donald K. Johnson, Honolulu, Hawaii The jig shown below will enable you to uniformly cut off four or four hundred stool legs at the required angle. Just bore a hole big enough to take the leg, through a block. Lay out the angle required by the splay of the leg and slot block with a backsaw. A backboard screwed to the block holds the jig securely in the bench vise as you make Like many woodworkers, I have the problem of having limited space in my workshop. Because of this fact, I've had to, in the past, deny myself the luxury of a drafting table. To remedy that problem, I added a space saving, fold-away drafting table at one end of my workbench. When not in use, the legs simply fold under the plywood, allowing it to lay flat against the bench. Steve Snodgrass, Montezuma, Ind. Old croquet mallets make excellent wooden mallets for the workshop. Trim the ends to make the mallet about 4'/i in. long, and cut the handle to around 7'/j in. And I find a bicycle grip, added to the handle, will make it easier to get a good hand grip. Walter C. Lesniewski, Bethel, Conn. In a pinch, those heavy spring paper clips (sometimes called binder clips) can be used for light-duty clamping To insure that a wood screw stays permanently in place, add a drop or two of epoxy glue to the hole before driving the screw. If you are looking for something to do some rainy evening, you may want to consider making a set of dowel center markers. They are handy to have because they insure accurate dowel joints with a minimum of layout work. The dowels are fitted with common nails which are glued (with epoxy) into drilled holes so that the sharpened point protrudes about 1/16 in. The holes should be sized for a snug nail fit. To center drill the dowels accurately, drill a hole (the same diameter as the dowel) through a block. Tap the dowel in, then run the drill in from the other side. Insert the bit just far enough to mark the centerpoint. With this centerpoint as a guide, bore the hole for the nail. You will have to sand the dowels enough so that they can be easily inserted and removed from the holes. If you have a lathe, you can turn your own dowels from hardwood and shave them down for a perfect slip fit. A thin washer is glued (with epoxy) to the end of the dowel to prevent it from being pushed too far into the hole. The Woodworker's Journal pays $25 for reader-submitted shop tips that are published. Send your ideas (including sketch if necessary) to: The Woodworker's Journal, P.O. Box 1629. New Milford. CT 06776, Attention: Shop Tip Editor. We redraw all sketches so |