Woodworker's Journal 1985-9-2, страница 32

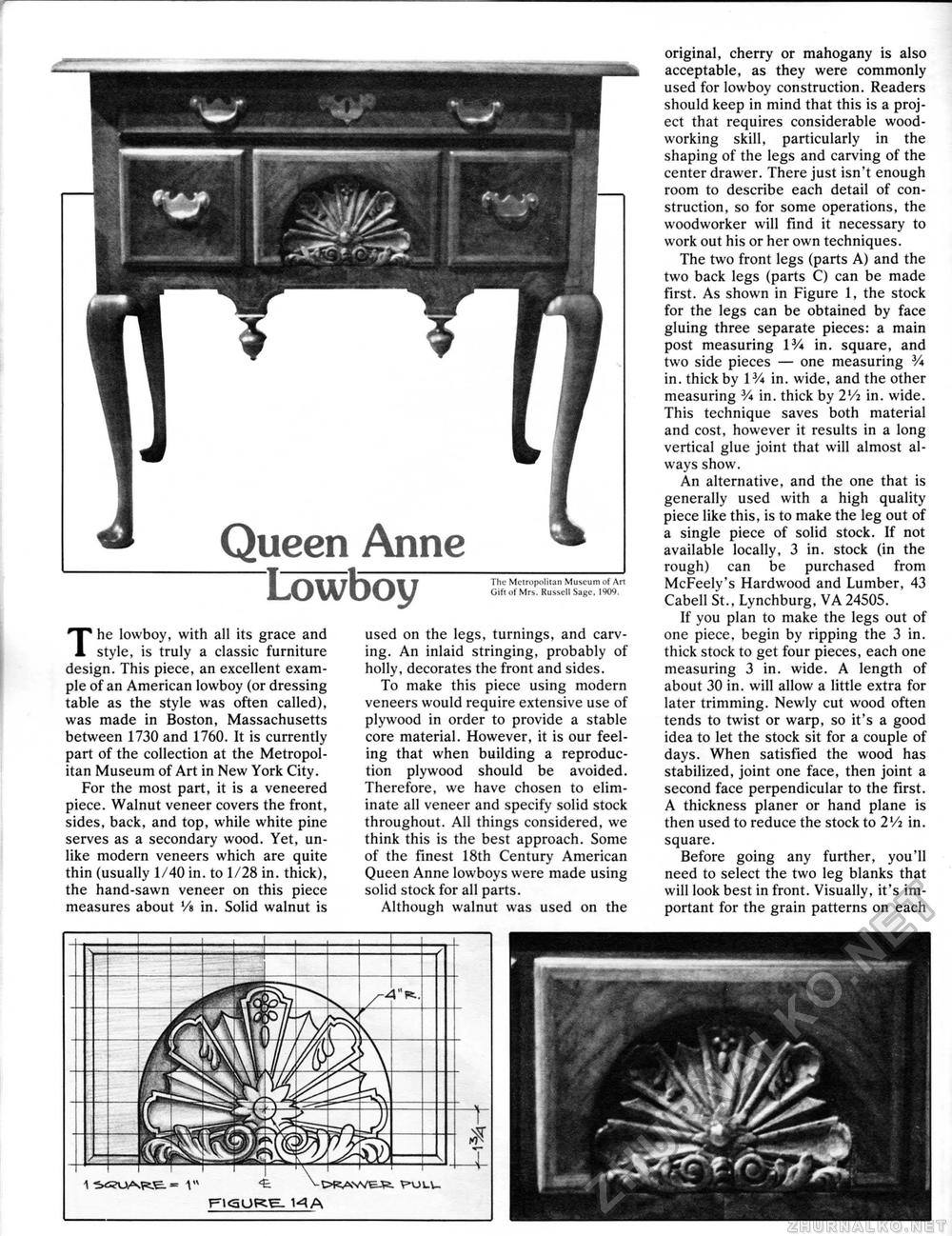

Lowboy The Metropolitan Museum of Art Gift of Mrs. Russell Sage. 1909. The lowboy, with all its grace and style, is truly a classic furniture design. This piece, an excellent example of an American lowboy (or dressing table as the style was often called), was made in Boston, Massachusetts between 1730 and 1760. It is currently part of the collection at the Metropolitan Museum of Art in New York City. For the most part, it is a veneered piece. Walnut veneer covers the front, sides, back, and top, while white pine serves as a secondary wood. Yet, unlike modern veneers which are quite thin (usually 1/40 in. to 1/28 in. thick), the hand-sawn veneer on this piece measures about V» in. Solid walnut is used on the legs, turnings, and carving. An inlaid stringing, probably of holly, decorates the front and sides. To make this piece using modern veneers would require extensive use of plywood in order to provide a stable core material. However, it is our feeling that when building a reproduction plywood should be avoided. Therefore, we have chosen to eliminate all veneer and specify solid stock throughout. All things considered, we think this is the best approach. Some of the finest 18th Century American Queen Anne lowboys were made using solid stock for all parts. Although walnut was used on the original, cherry or mahogany is also acceptable, as they were commonly used for lowboy construction. Readers should keep in mind that this is a project that requires considerable woodworking skill, particularly in the shaping of the legs and carving of the center drawer. There just isn't enough room to describe each detail of construction, so for some operations, the woodworker will find it necessary to work out his or her own techniques. The two front legs (parts A) and the two back legs (parts C) can be made first. As shown in Figure 1, the stock for the legs can be obtained by face gluing three separate pieces: a main post measuring IV* in. square, and two side pieces — one measuring V* in. thick by IV* in. wide, and the other measuring V* in. thick by 2Vi in. wide. This technique saves both material and cost, however it results in a long vertical glue joint that will almost always show. An alternative, and the one that is generally used with a high quality piece like this, is to make the leg out of a single piece of solid stock. If not available locally, 3 in. stock (in the rough) can be purchased from McFeely's Hardwood and Lumber, 43 Cabell St., Lynchburg, VA 24505. If you plan to make the legs out of one piece, begin by ripping the 3 in. thick stock to get four pieces, each one measuring 3 in. wide. A length of about 30 in. will allow a little extra for later trimming. Newly cut wood often tends to twist or warp, so it's a good idea to let the stock sit for a couple of days. When satisfied the wood has stabilized, joint one face, then joint a second face perpendicular to the first. A thickness planer or hand plane is then used to reduce the stock to 2Vi in. square. Before going any further, you'll need to select the two leg blanks that will look best in front. Visually, it's important for the grain patterns on each |