Woodworker's Journal 1985-9-2, страница 54

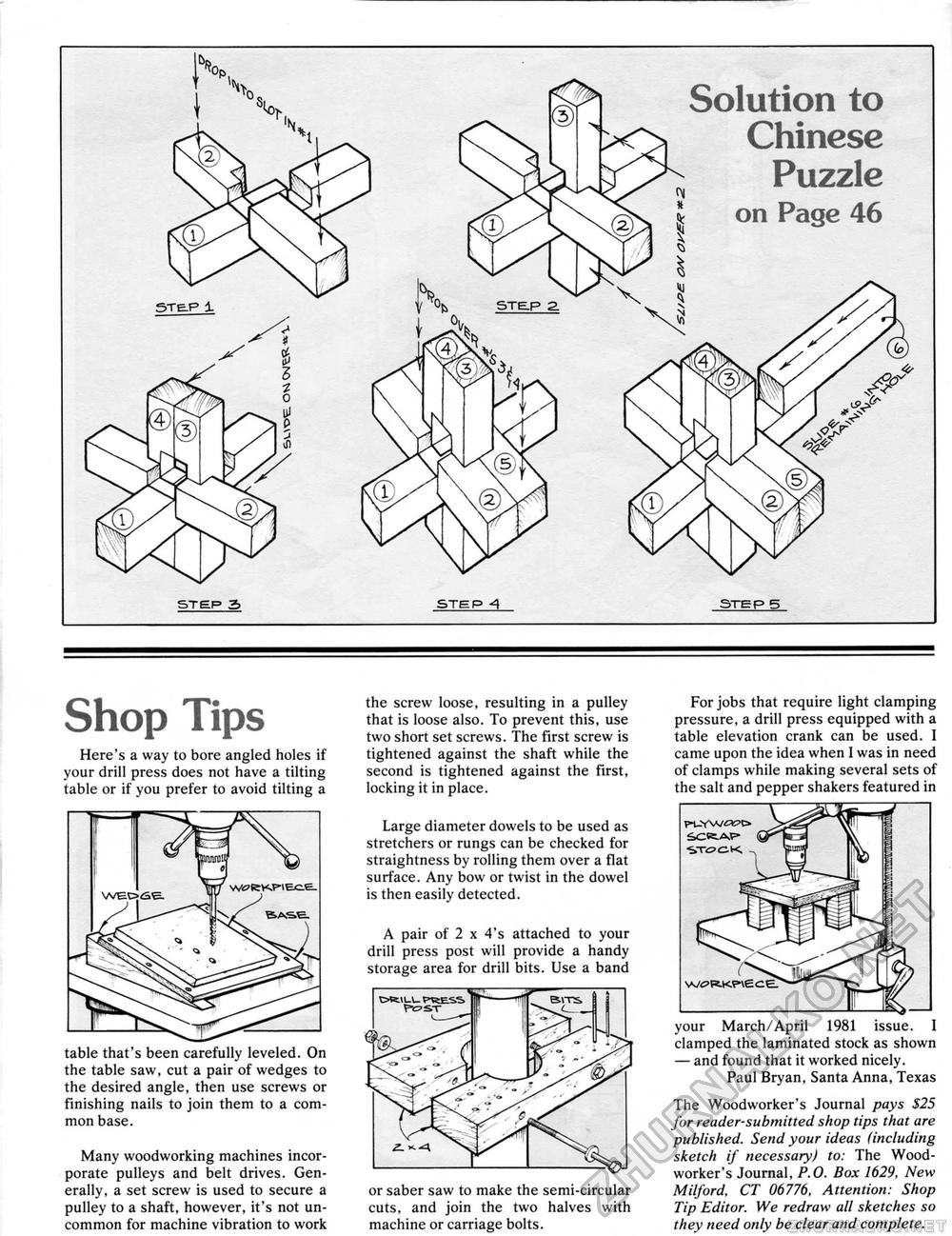

Solution to Chinese Puzzle on Page 46 STEP 5 STEP A STEP 5 Shop TipsHere's a way to bore angled holes if your drill press does not have a tilting table or if you prefer to avoid tilting a table that's been carefully leveled. On the table saw, cut a pair of wedges to the desired angle, then use screws or finishing nails to join them to a common base. Many woodworking machines incorporate pulleys and belt drives. Generally, a set screw is used to secure a pulley to a shaft, however, it's not uncommon for machine vibration to work the screw loose, resulting in a pulley that is loose also. To prevent this, use two short set screws. The first screw is tightened against the shaft while the second is tightened against the first, locking it in place. Large diameter dowels to be used as stretchers or rungs can be checked for straightness by rolling them over a flat surface. Any bow or twist in the dowel is then easily detected. A pair of 2 x 4's attached to your drill press post will provide a handy storage area for drill bits. Use a band or saber saw to make the semi-circular cuts, and join the two halves with machine or carriage bolts. For jobs that require light clamping pressure, a drill press equipped with a table elevation crank can be used. I came upon the idea when I was in need of clamps while making several sets of the salt and pepper shakers featured in your March/April 1981 issue. I clamped the laminated stock as shown — and found that it worked nicely. Paul Bryan, Santa Anna, Texas The Woodworker's Journal pays $25 for reader-submitted shop tips that are published. Send your ideas (including sketch if necessary) to: The Woodworker's Journal, P.O. Box 1629, New Milford, CT 06776, Attention: Shop Tip Editor. We redraw all sketches so they need only be clear and complete. |