Woodworker's Journal 1985-9-5, страница 66

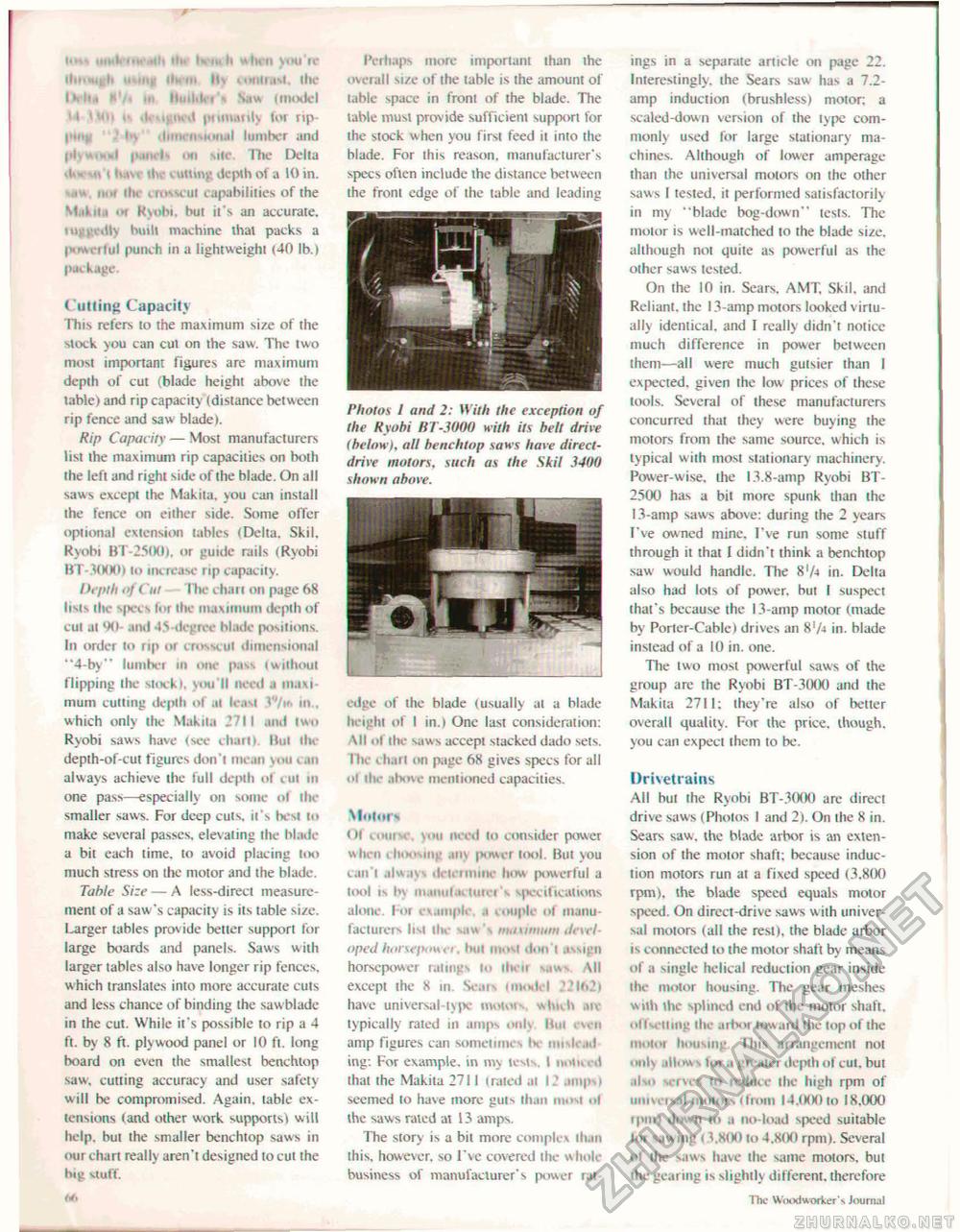

M»t IKHII iln Ik u< h «Inn yiHj 'rr iltrimi'h u> ntg lit* ut M\ * ihiii.isI. (lie IKl»t H'/« Hi lluililii't Saw Minnie I i > «i> >nutl piumrtly lor rtp-l>t»t(f 1 i \ ilniiiTi.itiit.il lumber and |t.n«-|s mi mic. Tlte Delia ii-- .« i it.f., tit -» utttng depth of a 10 in. ........ ilit trit<Acul capabilities of the M.ililn >>i Kyolu, bui it's an accurate, ui^i'illy built machine that packs a I* tsvcrlul punch in a lightweight <40 lb.) package. Cutting Capacity This refers to the maximum size of the stock you can cut on the saw. The two most important figures are maximum depth of cut (blade height above the table) and rip capacity (distance between rip fence and saw blade). Rip Capacity — Most manufacturers list the maximum rip capacities on both ihe left and right side of the blade. On all saws except the Makita. you can install the fence on either side. Some offer optional extension tables (Delta. Skit. Ryobi Hi 2500), or guide rails (Ryobi BT-3000) to increase rip capacity. Depth of Cut The chart on page 68 lists the specs for the maximum depth of eul at W- and 45-degree blade positions. In order to rip or crosscut dimensional "4-by" lumber ill ttne past (without flipping the siockt. ><m It need a maxi mum cutting depth of at le.tsi 1 ut which only ihe Makita 2711 and I wo Ryobi saws have (see chart > Hut tin depth-of-cut figures don't mean v.m t an always achieve the full depth ol cut in one pass—especially on some of the smaller saws. For deep cuts, it's Ivsi to make several passes, elevating the blade a bit each time, lo avoid placing loo much stress on the motor and the blade. Table Size —- A less-direct measurement of a saw's capacity is its table size, l-arger tables provide bener support for large boards and panels. Saws with larger tables also have longer rip fences, which translates into more accurate cuts and less chance of binding the saw blade in ihe cut. While it's possible to rip a 4 ft. by 8 ft, plywood panel or 10 ft. long board on even the smallest benchtop saw. cutting accuracy and user safety will be compromised. Again, table extensions (and other work supports) will help, but the smaller benchtop saws in our chart really aren't designed to cut the big stuff. 66 Perhaps more important than the overall size of the table is the amount of table space in front of the blade. The table must provide sufficient support for the stock when you first feed it into the blade. For this reason, manufacturer's specs often include the distance between the front edge of the table and leading Photos I and 2: With the exception of the Ryobi BT-3000 with its belt drive (below), aU benchtop saws have direct-drive motors, such as the Skil 3400 shown above. edge of ihe blade (usually at a blade height of I in.} One last consideration: All <>l (he saws accept stacked dado sets. The t hart on page 68 gives specs for all ol ihe above mentioned capacities. Motors Of i our * \<hi need to consider power when choosing .m> j»owcr tool. But vou can't always determine how powerful a tool is by manutacturci's specifications alone, for extmiplt a couple of manufacturers list ihe s;i* \ nunwium developed horsepower, but most don i assign horsepower ratings lo dvit saws All except the X in. Seats imodel 22l<»2) have universal-type motors Mmh aiv typically rated in amps oiiK Bui even amp figures can somen m* . I* mi U id ing: For example, in my ICMs, I until. that the Makita 2711 (rated ai I .impsi seemed to have more guts than most .>1 the saws rated at 13 amps. The story is a bit more complex ili.m this, however, so I've covered the whole business of manufacturer's power r.u mgs in a separate arncle on page 22. Interestingly, the Sears saw has a 7.2-amp induction (brushless) motor: a scaled-dow n version of the type commonly used for large stationary machines. Although of lower amperage than the universal motors on the other saws I tested, it performed satisfactorily in my "blade bog-down'' tests. The motor is well-matched to the blade size, although not quite as powerful as the other saws tested. On the 10 in. Sears. AMT, Skil. and Reliant, the I3-amp motors looked virtually identical, and I really didn't notice much difference in power between them—all were much gutsier than I expected, given the low prices of these tools. Several of these manufacturers concurred that they were buying the motors from the same source, which is typical with most stationary machinery. Power-wise, the 13.8-amp Ryobi BT-2500 has a bit more spunk than the 13-amp saws above: during the 2 years I've owned mine. I've run some stuff through it that I didn't think a benchtop saw would handle. The 8'A in. Delta also had lots of power, but I suspect that's because the 13-amp motor (made by Porter-Cable) drives an S'/i in. blade instead of a 10 in. one. The two most powerful saws of the group are the Ryobi BT-3000 and the Makita 2711; they're also of better overall quality. For the price, though, you can expect them to be. Drivetrains All but the Ryobi BT-3000 are direct drive saws (Photos I and 2). On the 8 in. Sears saw. the blade arbor is an extension of the motor shaft; because induction motors run at a fixed speed (3.800 rpm), the blade speed equals motor speed. On direct-drive saws with universal motors (all the rest), the blade arbor is connected to the motor shaf t by means of a single helical reduction gear inside the motor housing. The gear meshes with the splmed end of the motor shaft, offsetting the arbor toward the top of the motoi housing Pits arrangement not unlv ullnws tin ,i greater depth ol cut, but also serves to retime the high rpm of urim i at im>i<ilroni I4.IKM) to 18,000 ipini tlimi) in a no-load speed suitable lot sawing (3,800 to 4.800 rpm). Several of the saws have the same motors, but the gearing is slightly different, therefore The Woodworker's journal |