Woodworker's Journal 1985-9-5, страница 67

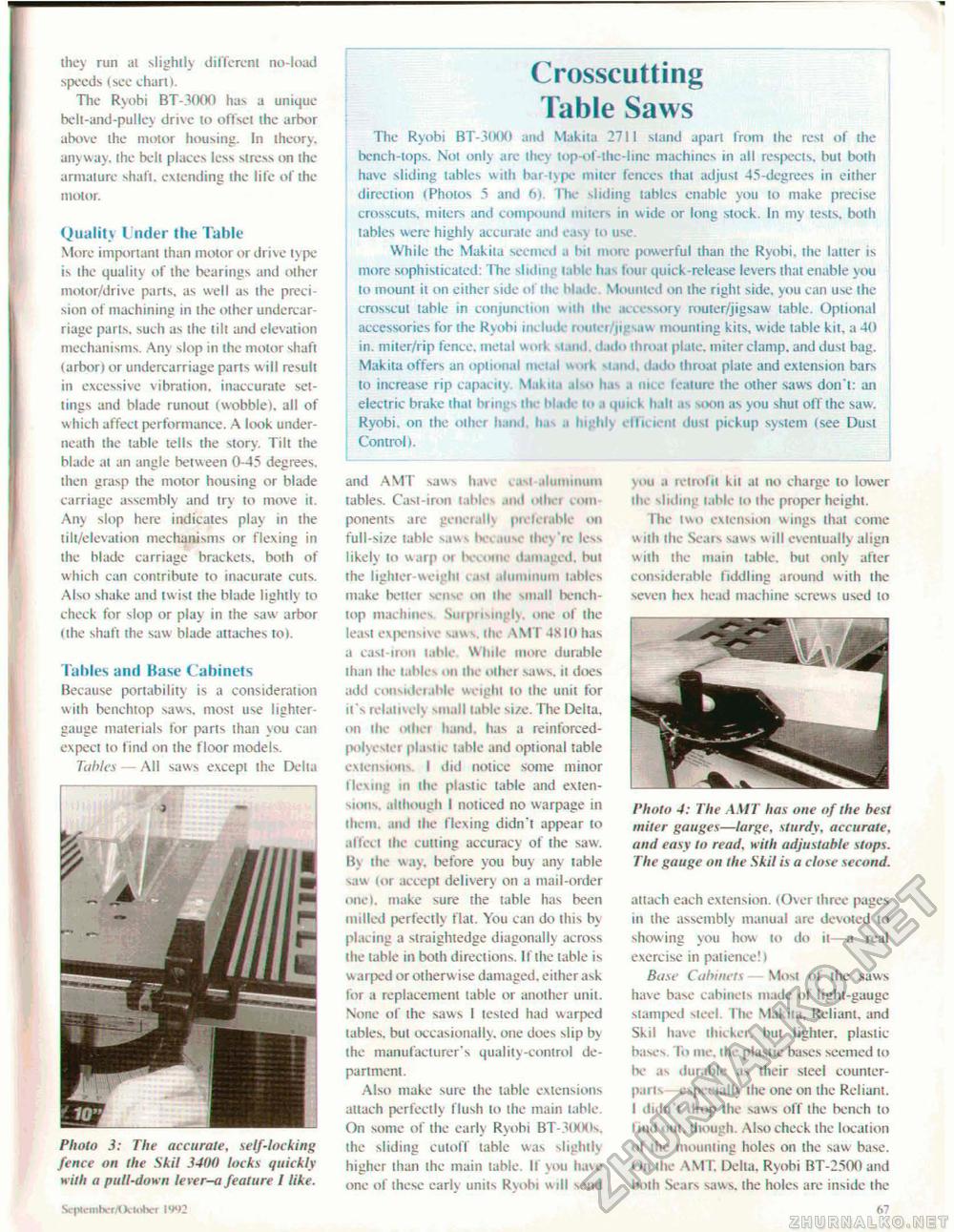

Crosscutting lable Saws The Ryobi BT-3<KX) and Makita 2711 siand apart from the rest of the bench-tops. Not onty are they top-of-lhe-linc machines in all respects, but both have sliding table-, with bar-type miter fences that adjust 45-degrees in either direction (Photos 5 and 6). I he sliding tables enahle you to make precise crosscuts, miters and compound miters in wide or long stock. In my tests, both tables were highly accurate and easy to use. While the Makita seemed a bit more powerful than the Ryobi, the latter is more sophisticated: The sliding table has four quick release levers that enable you to mount it on either side of the blade Mounted on the right side, you can use the crosscut lable in conjunction wiih Ihe accessory muter/jigsaw table. Optional accessories tor the Ryobi include n niter/jigsaw mounting kits, wide table kit. a 40 in, miter/rip fence, metal wor k si.uid. d.idn lhm.it plate, miter clamp, and dust bag. Makita offers an optional meial work st.md, dado throat plate and extension bars to increase rip capacity Makita also has nice feature Ihe other saws don't: an electric brake that brings ihe ld.nl> in i quit k halt is soon as you shut off ihe saw. Ryobi. on ihe other hand, has a In lily efficient dust pickup system (see Dust Control). they run aL slightly different no-load speeds (see chart). The Ryobi BT-3000 has a unique belt-and-pulley drive to offset the arbor above the motor housing. In theory, anyway, the belt places less stress on the armature shaft, extending ihe life of ihe motor. Quality Under the Table More important than motor or drive type is the quality of the bearings and other motor/drive parts, as well as the precision of machining in the other undercarriage parts, such as the lilt and elevation mechanisms. Any slop in the motor shaft (arbor) or undercarriage parts will result in excessive vibration, inaccurate settings and blade runout (wobble), all of which affect performance. A look underneath the table tells the story. Tilt the blade at an angle between 0-45 degrees, then grasp the motor housing or blade carriage assembly and try to move it. Any slop here indicates play in the tilt/elevation mechanisms or flexing in the blade carriage brackets, both of which can contribute to inacurate cuts. Also shake and twist the blade lightly to check for slop or play in Ihe saw arbor (the shaft ihe saw blade attaches to). Tables and Base Cabinets Because portability is a consideration with benchtop saws, most use lighter-gauge materials for parts than you can expect to find on the floor models. Tables All saws except Ihe Delia Photo 3: The accurate, self-locking fence on lite Skil 34(H) locks quickly with a pull-down lever—a feature I like. and AV1T saws have casi aluminum tables. Cast-iron tables and other com ponents are generally preferable on full-size table s.ivvs his tuse they 're less likely to warp or bccomc damaged, bui the lighter-weight vast aluminum tables make belter sense on the small bench-top machines. Surprisingly, one of the least expensive saws, the AMT 4K10 has a cast-iron table While more durable than the tables on ihe oilier saws, il does add considerable weight to the unit for it's relatively small (able size. The Delta, on ilk- othei hand, has a reinforced-polyesiei plastic table and optional table extensions 1 did notice some minor flexing in the plastic (able and extensions. ,ilthi High I noticed no warpage in them, and the flexing didn't appear to affect ihe cutting accuracy of the saw. By the way. lie fore you buy any table saw lor accept delivery on a mail-order onemake sure the table has been milled perfectly flat. You c an do this bv placing a straightedge diagonally across the lable in both directions. If the table is warped or olherw ise damaged, eilher ask lor a replacemeni lable or another unit. None of ihe saws 1 tested had warped tables, but occasionally, one does slip by the manufacturer's quality-control department. Also make sure ihe lable extensions attach perfectly flush lo the main table. On some of the early Ryobi BT-3000s. the sliding cutoff table was slighily higher than the main table. If you have one of these early units Ryobi will send you a retrofit kit ai no charge lo lower the sliding table lo ihe proper height. The two extension wings that come with ihe Sears saws uill eventually align with the main table, but only after considerable fiddling around with the seven hex head machine screws used to "mJm nywil Photo 4: The AMT has one of the heat miter gauge*—large, sturdy, accurate, and easy to read, with adjustable slops. The gauge on the Skil is a close second. attach each extension. (Over three pages in the assembly manual are devoted lo showing you how io do ii—a real exercise in patience?) Base Cabinetv Mosl of the saws have base cabinets made of liglu-gaugc stamped sieel. lite Makita. Reliant, and Skil have thicker, but lighter, plastic bases lo me. ihe plasiic bases seemed to he as durable as their sleel counter-paris especially the one on the Reliant. I didn'i drop the saws off the bench to find out. though. Also check ihe location mI the mounting holes on the saw base. On Ihe AMT. Delia. Ryobi BT-2500 and both Sears saws, the holes are inside the ScptciiiherKVwher l<M2 67 |