Woodworker's Journal 1992-16-5, страница 57

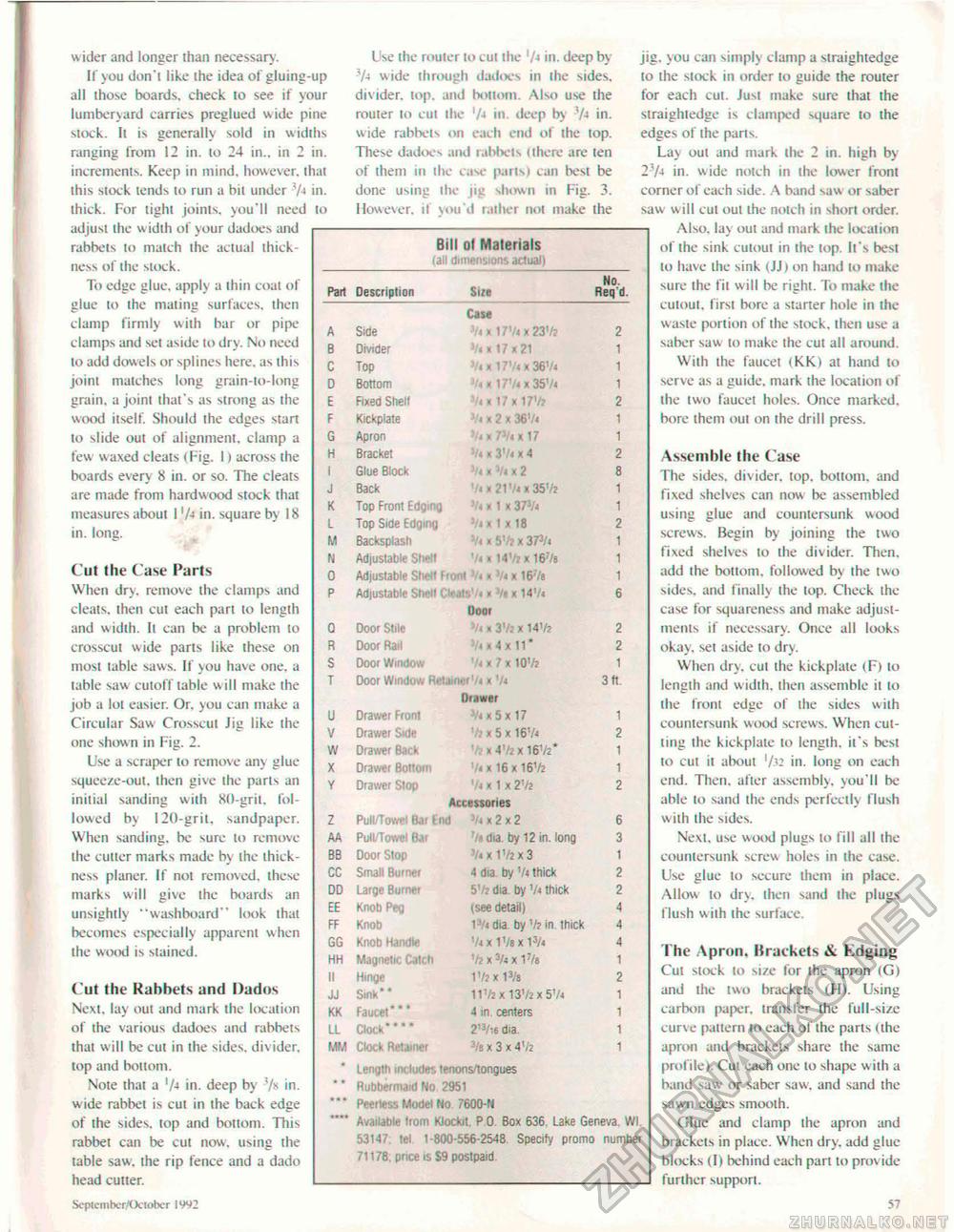

tt ider and longer than necessary. If you don'i like ihe idea of gluing-up all those boards, check to see if your lumberyard carries preglued wide pine stock. It is generally sold in widths ranging from 12 in. to 24 in., in 2 in. increments. Keep in mind, however, that this stock lends lo run a bil under V* in. thick. For tight joints, you'll need to adjust the w idth of your dadoes and rabbets to match the actual thickness of the stock. To edge glue, apply a thin coat of glue to the mating surfaces, then clamp firmly with bar or pipe clamps and set aside to dry. No need to add dowels or splines here, as this joint matches long grain-to-long grain, a joint that's as strong as the wood itself. Should the edges start to slide out of alignment, clamp a few waxed cleats (Fig. 1) across the boards every 8 in. or so. The cleats are made from hardwood stock that measures about 1'/-»in. square by 18 in. long. Cut the Case Parts When dry. remove the clamps and cleats, then cut each part to length and width. It can be a problem to crosscut wide parts like these on most table saws. If you have one. a table saw cutoff table will make the job a lot easier. Or. you can make a Circular Saw Crosscut Jig like the one shown in Fig. 2. Use a scraper to remove any glue squeeze-out. then give the parts an initial sanding with 80-gril. followed by 120-grit. sandpaper. When sanding, be sure lo remove the cutter marks made by the thickness planer. If not removed, these marks will give the boards an unsightly "washboard" look thai becomes especially apparent when the wood is stained. Use the router to cut the l/4 in. deep by ?/4 wide through dadoes in the sides, divider, top. and bottom. Also use the router to cut lite '/•* in. deep bv 7-» in. wide rabbets on each end of the top. These dadoes and rabbets (there are ten of them in the case parts) can best be done using ihe jig shown in Fig. 3. However, if you'd rather not make the jig. you can simply clamp a straightedge to ihe stock in order to guide the router for each cut. Just make sure that the straightedge is clamped Nquare to the edges of the parts. Lay out and mark the 2 in. high by 23A in. wide notch in the lower front corner of each side. A band saw or saber saw will cut out the notch in short order. Also, lay out and mark the location of the sink cutout in the top. It's best to have the sink (JJ) on hand lo make sure the fit will be right. To make the cutout, first bore a starter hole in the waste portion of the stock, then use a saber saw lo make the cut all around. With the faucet (KK) at hand to serve as a guide, mark ihe location of the two faucet holes. Once marked, bore them out on the drill press. Assemble the Case The sides, divider, top. bottom, and fixed shelves can now be assembled using glue and countersunk wood screws. Begin by joining the two fixed shelves to the divider. Then, add the bottom, followed by the two sides, and finally the top. Check the case for squareness and make adjustments if necessary. Once all looks okay, set aside to dry. When dry, cut the kickplate (F> to length and width, then assemble ii to the front edge of the sides with countersunk wood screws. When culling the kickplate to length, it's best to cut it about ]/m in. long on each end. Then, after assembly, you'll be able to sand the ends perfectly flush vviih the sides. Next, use wood plugs to fill all the countersunk screw holes in the case. Use glue to secure them in place. Allow to dry. then sand the plugs flush with the surface.

I he Apron. Brackets & Kdging Cui stock to si/e for the apron (G) and the two brackets (H). Using carbon paper, transfer the full-size curve pattern to each of the parts (the apron and brackets share the same profile). Cui each one lo shape with a band saw or saber saw. and sand the sawn edges smooth. Glue and clamp the apron and brackets in place. When dry. add glue blocks (I) behind each part to prov ide further support. 57 Cut the Rabbets and Dados Next, lay out and mark the location of the various dadoes and rabbets that will be cut in the sides, divider, top and bottom. Note that a '/-» in. deep by V» in. wide rabbet is cut in the back edge of the sides, top and bottom. This rabbet can be cut now. using the table saw. the rip fence and a dado head cutter. Scpicmbcr/Ociobcr 1992 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||