Woodworker's Journal 1992-16-5, страница 59

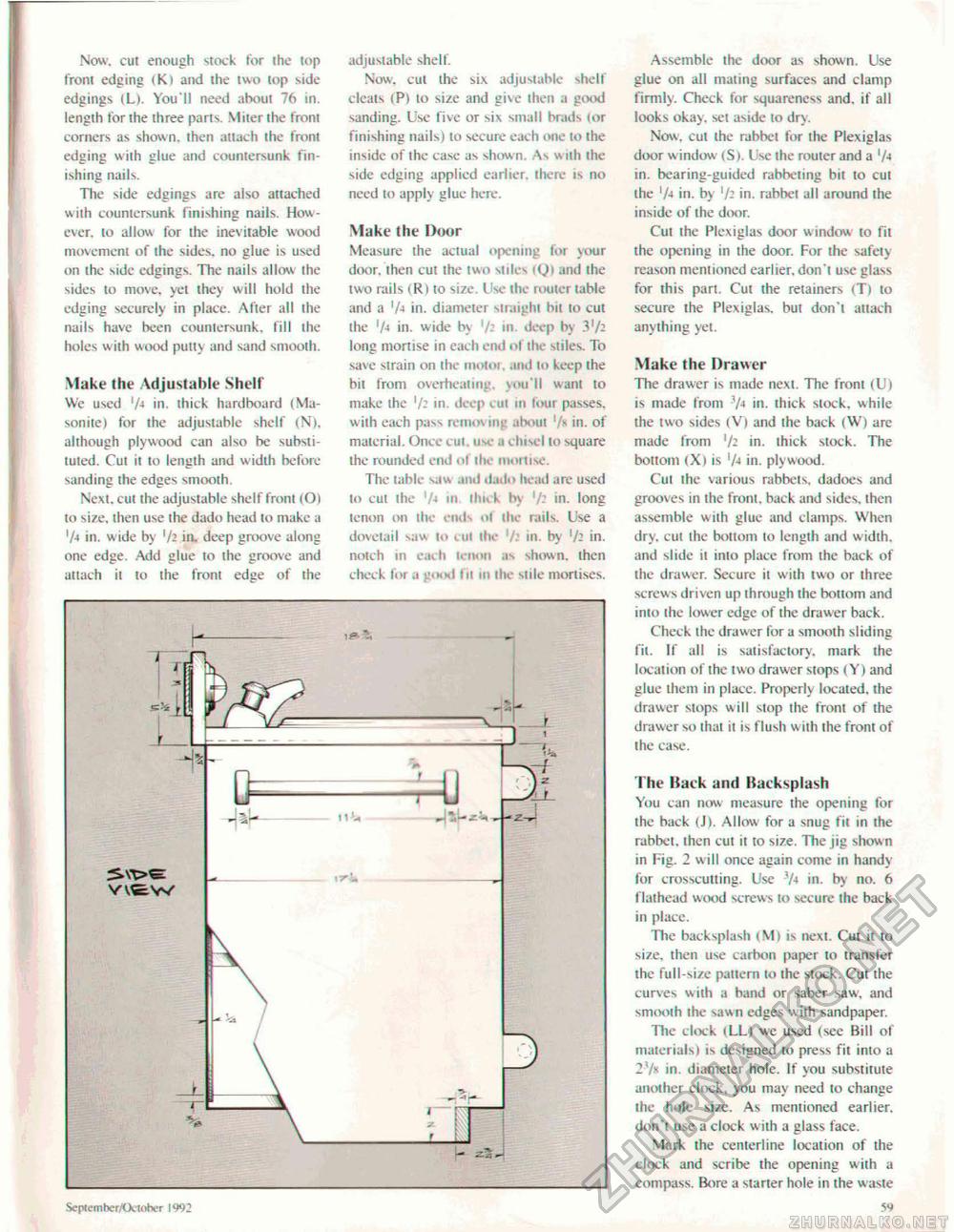

Now. cut enough stock for the top front edging (K) and the two top side edgings (L). You'll need ahout 76 in. length for the three parts. Miter the front corners as shown, then attach the front edging with glue and countersunk finishing nails. The side edgings are also attached with countersunk finishing nails. However. to allow for the inevitable wood movement of the sides, no glue is used on the side edgings. The nails allow the sides to move, yet they will hold the edging securely in place. After all the nails have been countersunk, fill the holes w ith wood putty and sand smooth. Make the Adjustable Shelf We used '/* in. (hick hardboard (Ma-sonite) for the adjustable shelf (N). although plywood can also be substituted. Cut it to length and width before sanding the edges smooth. Next, cut the adjustable shelf front (O) to size, then use the dado head to make a in. w ide by 1 /z in. deep groove along one edge. Add glue to the groove and attach it to the front edge of the adjustable shelf. Now, cut the six adjustable shelf cleats (P| to size and give then a good sanding. Use five or six small brads (or finishing nails) to secure each one to the inside of the case as shown. As w ith ihe side edging applied earlier, there t-. no need to apply glue here. Make the Door Measure the actual opening for your door, then cut the two stiles and the two rails (R l to size. Use the router table and a 'A in, diameter straight bit to cut the 'A in. wide by '/: in. deep by Vh long mortise in each end ol the stiles. To save strain on ihe motor, and to keep the bit from overheating, you'll want to make the 7- in. deep cut in four passes, with each pass removing about 7* in. of material. Once cut. use- a chisel to square the rounded end of die mortise. The table saw and dado head are used lo cut the 'A in thick by yfc in. long tenon on Ihe ends of the rails. Use a dovetail saw to cut ihe in. by 72 in. notch in each tenon as shown, then check for a good fit m Ihe stile mortises. September/October 1992 Assemble the door as shown. Use glue on all mating surfaces and clamp firmly. Check for squareness and. if all looks okay, sei aside to dry. Now, cut the rabbet for the Plexiglas door window (S). Use the router and a 'A in. bearing-guided rabbeting bit to cut the 'A in. by '/- in. rabbel ail around the inside of the door. Cut the Plexiglas door window to fit the opening in the door. For the safety reason mentioned earlier, don't use glass for this part. Cut the retainers (T) to secure the Plexiglas. but don't attach anything yet. Make the Drawer The drawer is made next. The front (U) is made from V» in. thick stock, while the two sides (V) and the back (W) are made from '/- in. thick slock. The bottom <Xi is 'A in. plywood. Cut the various rabbets, dadoes and grooves in the front, back and sides, then assemble with glue and clamps. When dry. cut the bottom to length and w idth. and slide it into place from the back of the drawer. Secure it with two or three screws driven up through the bottom and into the lower edge of the drawer back. Check the drawer for a smooth sliding fit. If all is satisfactory, mark the location of the two drawer stops (Y) and glue them in place. Properly located, the drawer stops w ill stop the front of the drawer so that it is flush with the front of the case. The Hack and Backsplush You can now measure the opening for the back (J). Allow for a snug fit in the rabbel. then cut it to size. The jig show n in Fig. 2 will once again come in handy for crosscutting. Use 3A in. by no. 6 flathead wood screws to secure the back in place. The back splash (M) is next. Cut it to size, then use carbon paper to transfer the full-size pattern to the stock. Cut the curves with a hand or saber saw, and smooth the saw n edges w ith sandpaper. Hie clock (LL) we used (see Bill of materials) is designed to press fit into a 27* m. diameter hole. If you substitute another clock, you may need lo change the hole size. As mentioned earlier, don'l use a clock with a glass face. Mark the centerline location of the clock and scribe the opening with a compass. Bore a siarter hole in the waste 59 |