Woodworker's Journal 1992-16-6, страница 20

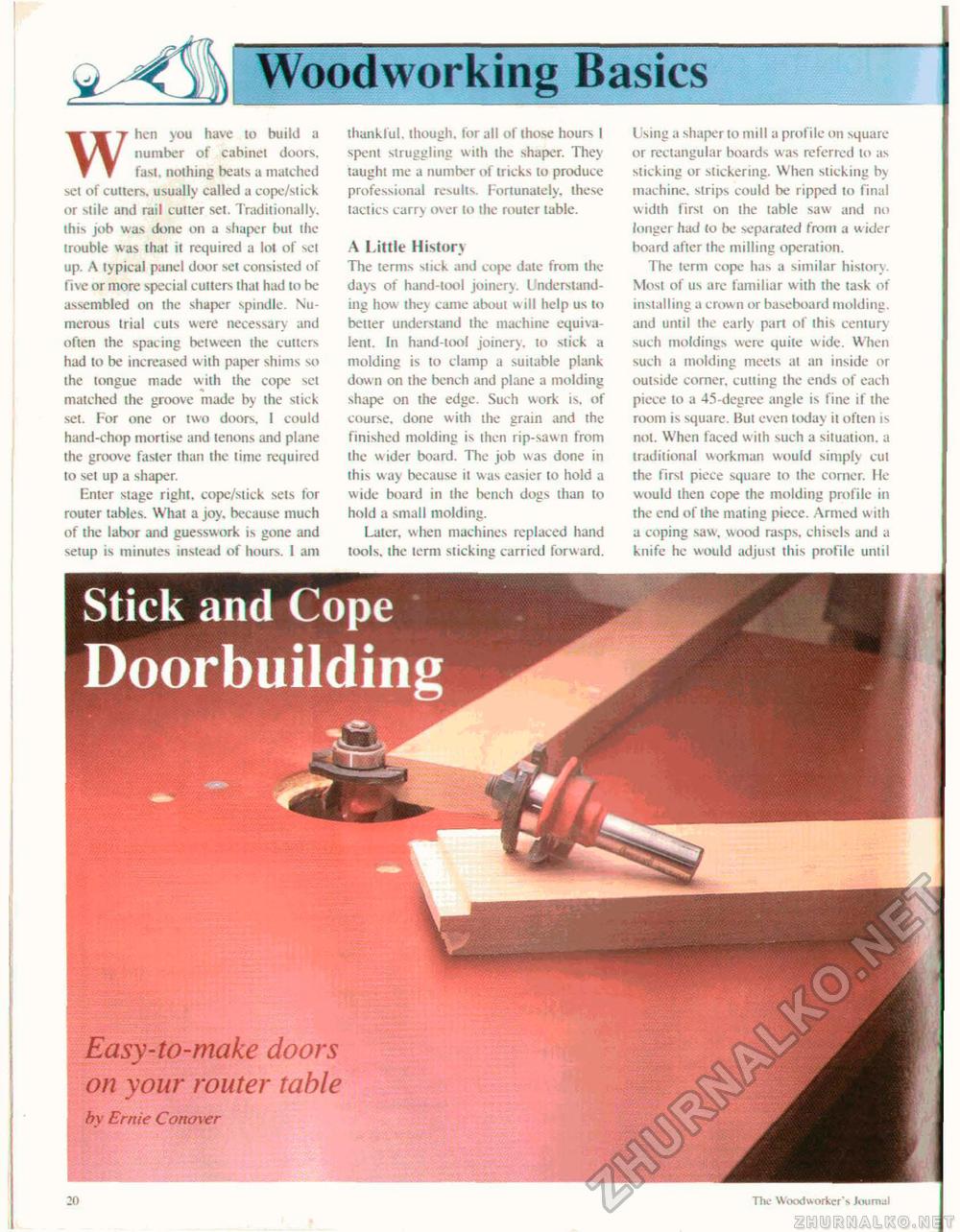

Woodworking Basics When you have to build a number of cabinct doors, fast, nothing beats a matched set of cutters, usually called a cope/stick or stile and rail culler set. Traditionally, this job was done 011 a shaper but the trouble was that it required a lot of set up. A ty pical panel door set consisted of five or more special cutlers that had to be assembled on the shaper spindle. Numerous trial cuts were necessary and often the spacing between the cutters had to be increased with paper shims so the tongue made with the cope set matched the groove made by the stick set. For one or two doors. I could hand-chop mortise and tenons and plane the groove faster than the time required to set up a shaper. Enter stage right, cope/stick sets for router tables. What a joy. because much of the labor and guesswork is gone and setup is minutes instead of hours. I am thankful, though, for all of those hours I spent struggling with the shaper. They taught me a number of tricks to produce professional results. Fortunately, these tactics carr\ over to the router table. A Little History The terms stick and cope date from the days of hand-tool joinery. Understanding how the\ came about will help us to better understand the machine equivalent. In hand-too! joinery, to stick a molding is to clamp a suitable plank dow n on the bench and plane a molding shape on the edge. Such work is, of course, done with the grain and the finished molding is then rip-sawn from the wider board. The job was done in this way because it was easier to hold a wide board in the bench dogs than to hold a small molding. Later, when machines replaced hand tools, the term sticking carried forward. Using a shaper 10 mill a profile on square or rectangular boards was referred It) as sticking or stickering. When sticking by machine, strips could be ripped to final width first on the table saw and no longer had to be separated front a w icier board after the milling operation. The term cope lias a similar history. Most of us are familiar with the task of installing a crown or baseboard molding, and until the early part of this century such moldings were quite wide. When such a molding meets at an inside or outside corner, cutting the ends of each piece to a 45-degree angle is fine if the room is square. But even today it often is not. When faced with such a situation, a traditional workman would simply cut the first piece square to the corner. He would then cope the molding profile in the end of the mating piece. Armed w ith a coping saw, wood rasps, chisels and a knife he would adjust this profile until Easy-to-make doors on your router table bx Ernie Conover •4K The Woodworker's Journal |