Woodworker's Journal 1992-16-6, страница 22

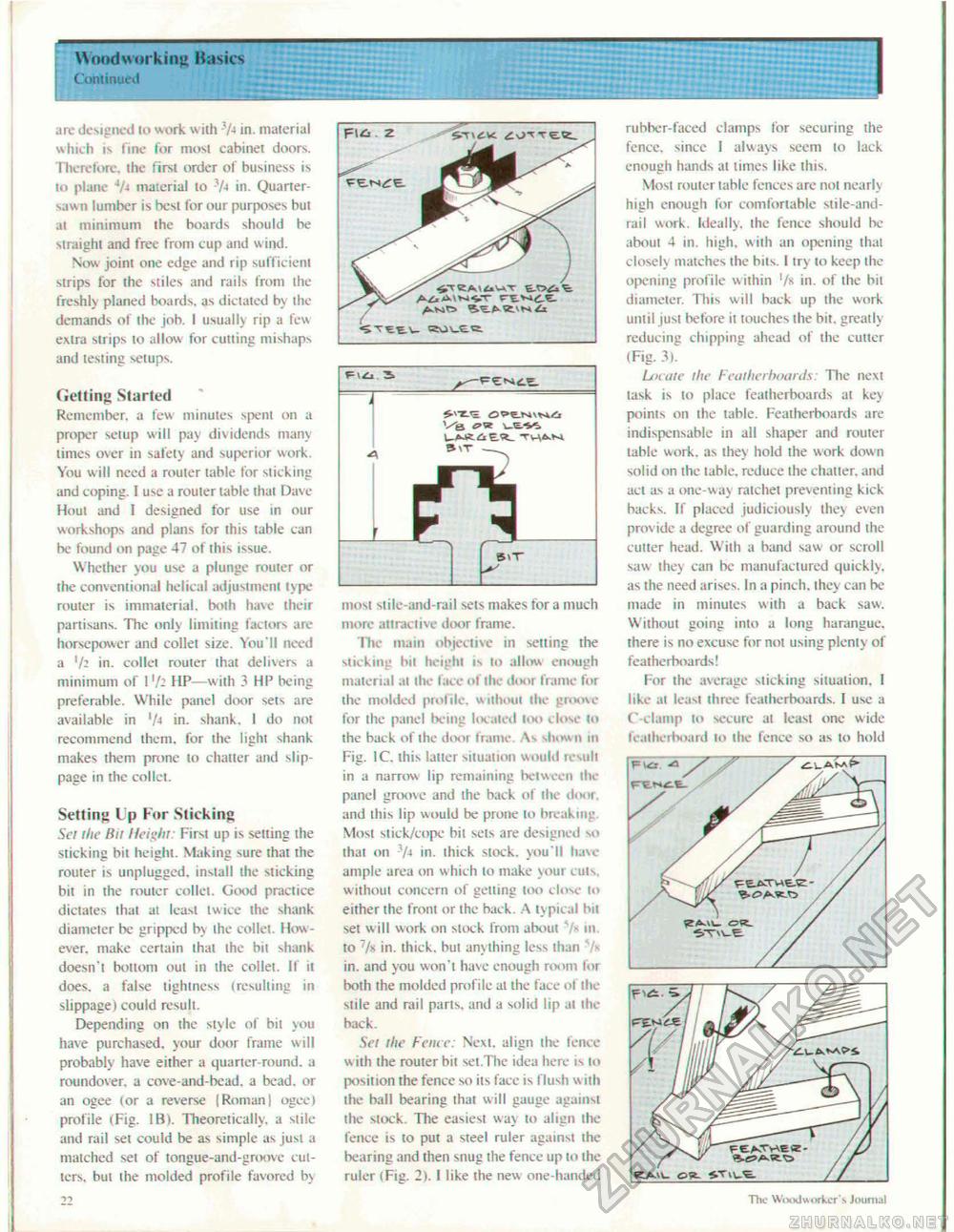

Woodworking Basics Cottlnued are designed to work with '/j in. material which is Tine for most cabinet doors. Therefore, the first order of business is to plane 4A material to V-< in. Quarter-saw n lumber is best for our purposes but at minimum Ihe boards should be straight and free from cup and wind. Now joint one edge and rip sufficient strips for the stiles and rails from the freshly planed boards, as dictated by the demands ol the job. I usually rip a few extra strips to allow for cutting mishaps and testing setups. Getting Started Remember, a few minutes spent on a proper setup will pay dividends many limes over in safety and superior work. You will need a router table for sticking and coping. I use a rouler table that Dave Hout and I designed for use in our workshops and plans for this table can be found on page 47 of this issue. Whether you use a plunge rouler or the conventional helical adjustment type router is immaterial, both have their partisans. The only limiting factors are horsepower and collel size. You'll need a '/i in, collel router lhat delixers a minimum of 1'/2 HP—with 3 HP being preferable. While panel door sets are available in '/» in. shank. I do not recommend them, for the light shank makes them prone to chatter and slippage in the collet. Setting I p For Sticking Sel the Hit Height First up is setting the sticking bit height. Making sure that the router is unplugged, insiall the sticking bit in ihe router collel. Good practice diclates that at least twice the shank diameter be gripped by ihe collet. However. make certain lhai the hit shank doesn't bottom out in the collet. If it does, a false tightness (resulting in slippage) could result. Depending on ihe style of bii you have purchased, your door frame will probably have either a quarter-round, a roundover. a cove-and-be ad. a bead, or an ogee (or a reverse (Roman) ogee I profile (Fig. IB I. Theoretically, a stile and rail sel could be as simple as just a matched set of tongue-and-groove cutters, but ihe molded profile favored by A^i AIN^T C-E-Vl^t ^Tttv- tsovEia. mosi stile-and-rail sets makes for a much more attractive door frame. The main objective in setting the sticking bn height is lo allow enough material al ihe face of the door frame for the molded profile, without ihe groove for ihe panel being located loo close to the back of ihe door frame. As shown in Fig. IC. this latter situation would result in a narrow lip remaining between ihe panel groove and the hack of the door, and this lip would be prone lo breaking Most stick/cope bii sets are designed so that on Vj in. thick slock, you'll have ample area on w hich lo make your cuts, without concern of getting too close to either the front or the back A typical bii set will work on slock from about V* in. to 7/» in. thick, but anything less than 7* in. and you won't have enough room for both ihe molded profile al the face ol Ihe stile and rail parls. and a solid lip at ihe hack. Set the Fence: Next, align the fence w ith the router bit set.The idea here is to position the fence so its face is flush w iih the ball bearing that will gauge againsl ihe siock. The easiest way to align the fence is to put a steel ruler against the bearing and then snug the fence up to the ruler (Fie. 2). I like the new one handed rubber-faced clamps for securing the fence, since I always seem lo lack enough hands al times like this. Most router table fences are not nearly high enough for comfortable stile-and-rail work. Ideally, the fence should be about 4 in. high, wiih an opening thai closeh matches the hits. I try to keep the opening profile within '/* in. of the hit diameter. This will back up the work until jusl before it touches ihe bit, greatly reducing chipping ahead of the cutter (Fig. 3). Locate the Featherboards: The next I ask is to place featherboards at key points on the table. Featherboards are indispensable in al! shaper and router table work, as they hold the work down solid on the table, reduce the challer. and act as a one-way ralchet preventing kick hacks. If placed judiciously they even provide a degree of guarding around the culler head. With a band saw or scroll saw they can be manufactured quickly, as the need arises. In a pinch, they can be made in minutes with a back saw. Without going into a long harangue, there is no excuse for noi using plenty of featherboards! For the average sticking situation. I like ai leasi three feaiherboards. I use a r clamp lo secure al least one wide foaiherboard lo the fence so as to hold The Wixulmirker's Journal Fli! 3. |