Woodworker's Journal 1993-17-1, страница 26

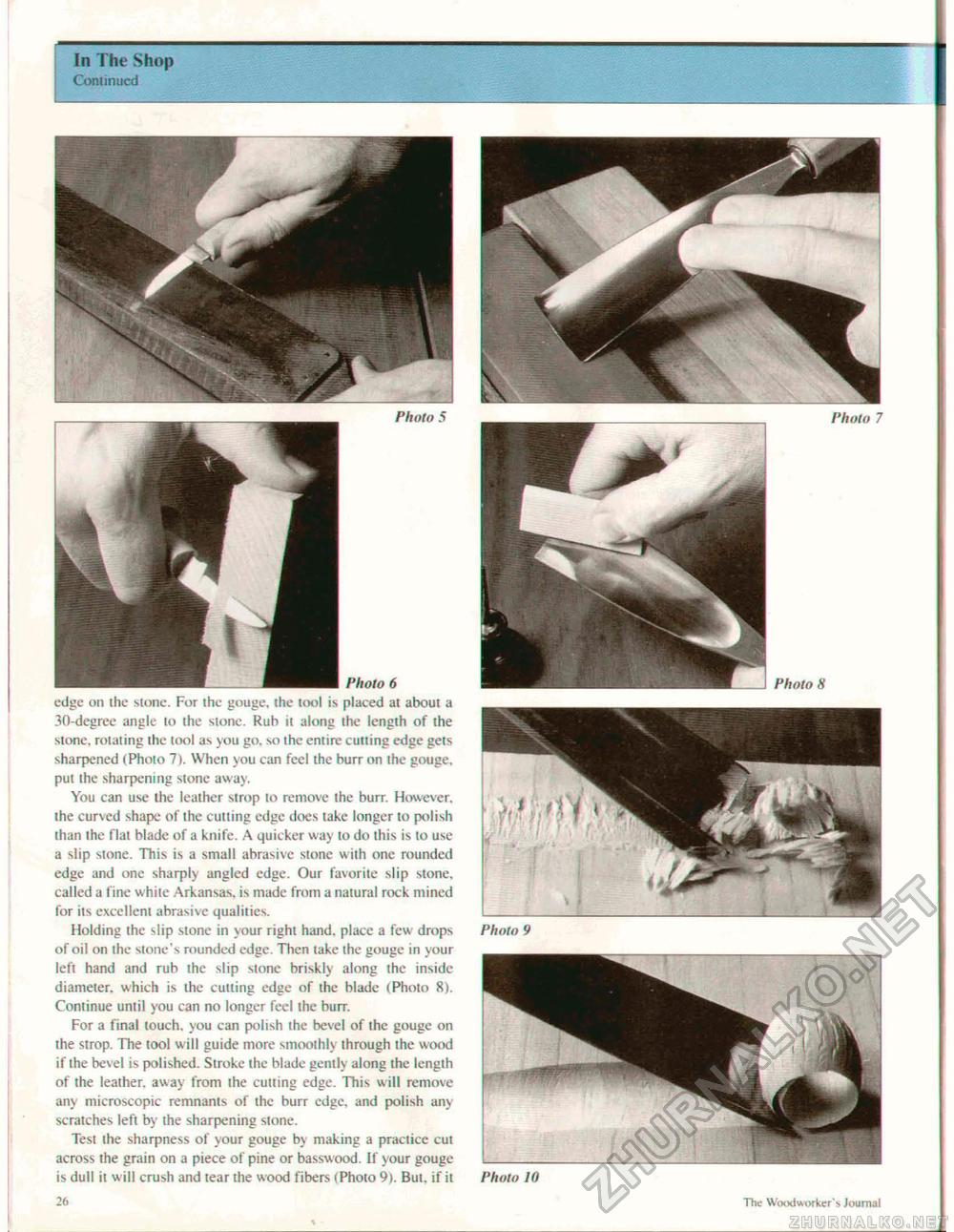

Photo 7 Photo 8 In The Shop Coniinucd Photo 9 Photo JO IX The Woodworker'1, Journal Photo 5 Photo 6 edge on the stone. For the gouge, the tool is placed at about a 30-degree angle to the stone. Rub it along the length of the stone, rotating the tool as you go, so the entire cutting edge gets sharpened (Photo 7When you can feel the burr on the gouge, put the sharpening stone away. You can use the leather strop to remove the burr. However, the curved shape of the cutting edge does take longer to polish than ihe flat blade of a knife. A quicker way lo do this is lo use a slip stone. This is a small abrasive slone with one rounded edge and one sharply angled edge. Our favorite slip stone, called a fine white Arkansas, is made from a natural rock mined for its excellent abrasive qualities. Holding the slip stone in your right hand, place a few drops of oil on the stone's rounded edge. Then lake the gouge in your left hand and rub the slip stone briskly along the inside diameter, which is the cutting edge ot the blade (Photo 8). Continue until you can no longer feel the burr. For a final touch, you can polish ihe bevel of the gouge on the strop. The tool will guide more smoothly through the wood if the bevel is polished. Stroke the blade gently along the length of the leather, away from the cutting edge. This will remove any microscopic remnants of the burr edge, and polish any scratches left by the sharpening stone. Test ihe sharpness of your gouge by making a practice cut across the grain on a piece of pine or basswood. If your gouge is dull it will crush and tear the wood fibers (Photo 9), But, if it |