Woodworker's Journal 1993-17-1, страница 57

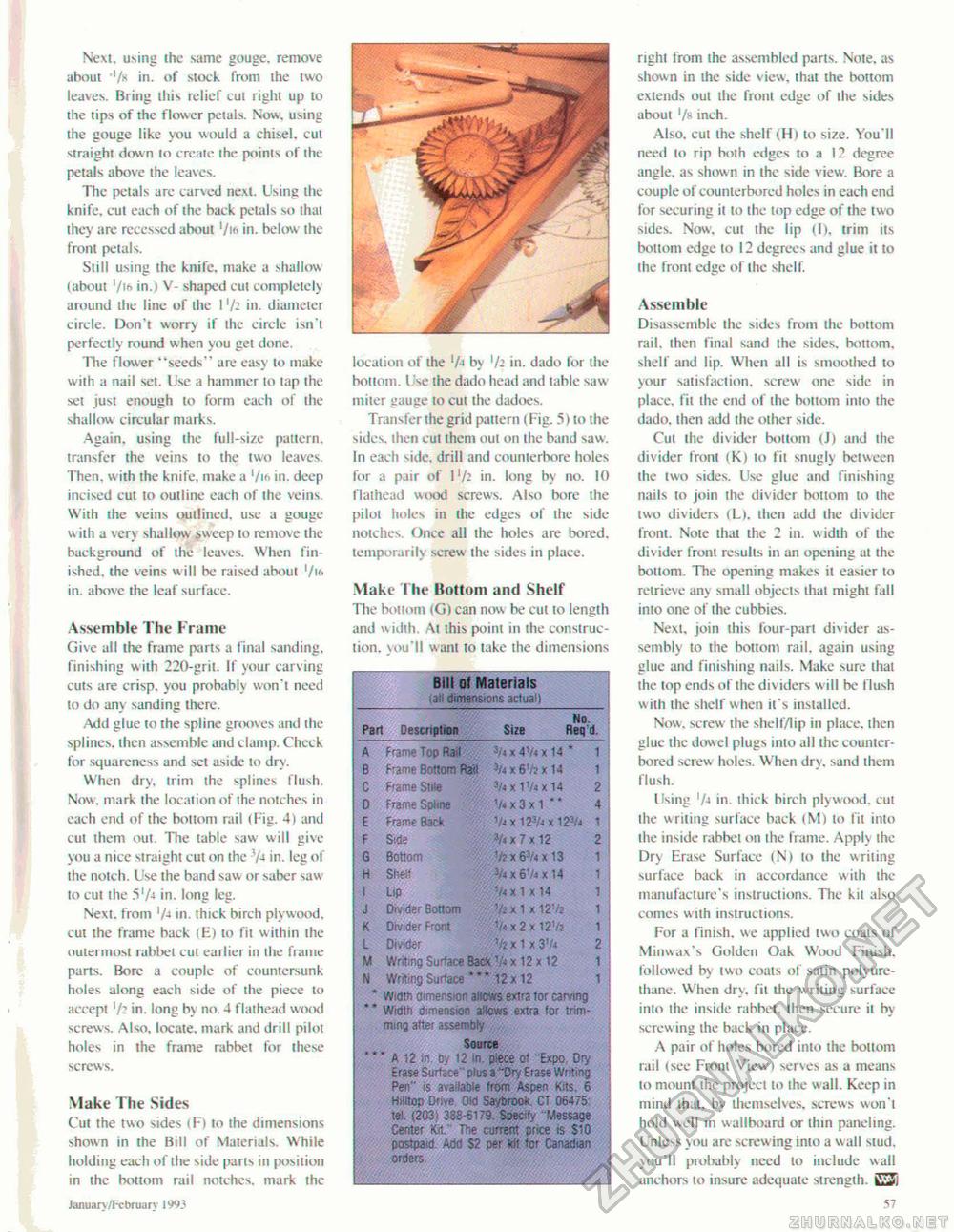

Next, using the same gouge, remove about '/x in. of stock from the two leaves. Bring this relief cut right up to the tips of the flower petals. Now. using the gouge tike you would a chisel, cut straight down to create the points of the petals above the leaves. The petals arc carved next. Using the knife, cul each of the back petals so that they are recessed about '/is in. below the front petals. Still using the knife, make a shallow (about '/•<> in.) V- shaped cut completely around the line of the 1'/- in. diameter circle. Don't worry if the circle isn't perfectly round when you get done. The flower "seeds" are easy to make with a nail set. Use a hammer to tap the set just enough to form each of the shallow circular marks. Again, using the full-size pattern, transfer the veins to the two leaves. Then, w ith the knife, make a l/» in. deep incised cut to outline each of the veins. With the veins outlined, use a gouge w ith a very shallow sweep lo remove the background of the leaves. When finished, the veins will be raised about Vi<< in. above the leaf surface. Assemble The Frame Give all the frame parts a final sanding, finishing with 220-grit. If your carving cuts are crisp, you probably won't need to do any sanding there. Add glue to the spline grooves and the splines, then assemble and clamp. Check for squareness and set aside to dry. When dry. trim the splines flush. Now, mark the location of the notches in each end of the bottom rail (Tig. 4) and cul them out. The table saw will give you a nicc straight cut on the V-t in. leg of ihe notch. Use the band saw or saber saw to cut the 5'A in. long leg. Next, from 'A in. thick birch plywood, cut the frame back (1£) to fit w ithin the outermost rabbet cut earlier in the frame parts. Bore a couple of countersunk holes along each side of the piece to accept '/s in. long by no. 4 flathead wood screws. Also, locate, mark and drill pilot holes in the frame rabbet for these screws. Make The Sides Cut the two sides <Fl to the dimensions shown in the Bill of Materials. While holding each of the side parts in position in the bottom rail notches, mark the Januan/l-'cbruary 1993 location of the 'A by in. dado For the bottom. I se the dado head and table saw miter gauge to cul the dadoes. Transfer the grid pattern (Fig, 5) to the sides, then cut them out on the band saw. In each side, drill and counterbore holes for a pair of I'/- in. long by no. 10 flathead wood screws. Also bore the pilot holes in the edges of the side notches. Once all the holes are bored, temporarily screw ihe sides in place. Make Ihe Bottom and Shelf The bottom (G) can now be cut to length and width. At this point in ihe construction. you'll wanl to take the dimensions

* Width dimension allows extra for carving *" Width dimension allows extra (or trimming attef assembly Source *** A. 12 m by ?2 in. piece of Expo, Dry Erase Surface" plus a "Dry Erase Writing Pen" is available from Aspen Kits. 6 Hilltop Drive, Oiti Saytmwk- CT 06475; tel. (2031 338-6179. Specify "Message Center Kit.' The currem price rs StO postpaid. Add S2 per kit for Canadian orders mm, c.?.®■ ■;. .,:.,-lis^;,■ right from the assembled parts. Note, as shown in the side view, that the bottom extends out the from edge of the sides about '/» inch. Also, cut the shelf (Hi to size. You'll need lo rip both edges to a 12 degree angle, as shown in the side view. Bore a couple of counterborcd holes in each end for securing il lo the top edge of the two sides. Now, cut the lip (I), trim its bottom edge to 12 degrees and glue it to Ihe front edge of the shelf. Assemble Disassemble the sides from the bottom rail, then final sand Ihe sides, bottom, shelf and lip. When all is smoothed to your satisfaction, screw tine side in place, fit the end of the bottom into the dado, then add the other side. Cul the divider bottom (J) and the divider front (K) to fit snugly between ihe two sides. Use glue and finishing nails to join the divider bottom to the two dividers (L), then add the divider front. Note that ihe 2 in. width of ihe divider from results in an opening at the bottom The opening makes il easier lo retrieve any small objects that might fall into one of the cubbies. Next, join this four-part divider assembly to the bottom rail, again using glue and finishing nails. Make sure that the top ends of the dividers will be flush w ith the shelf when it's installed. Now. screw the shelf/lip in place, then glue the dowel plugs into all the counter-bored screw holes. When dry. sand ihem flush. Using 'A in. thick birch plywood. cut the writing surface back (M) to fit into the inside rabhel on the frame. Apply the Dry Erase Surface (N) to the writing surface back in accordance with the manufacture's instructions. The kit also comes with instructions. For a finish, we applied two coals of Minwax's Golden Oak Wood Finish, followed h\ two coats of satin polyure-thane. When dry. fit the writing surface into the inside rabbet, then secure il by-screwing the back in place. A pair of holes bored into the bottom rail (see Front View > serves as a means to mount the project to the wall. Keep in mind that, by themselves, screws won't hold well in wall board or thin paneling. Unless you are screwing into a w all stud, you'll probably need to include wall anchors to insure adequate strength. E3i 57 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||