Woodworker's Journal 1994-18-3, страница 23

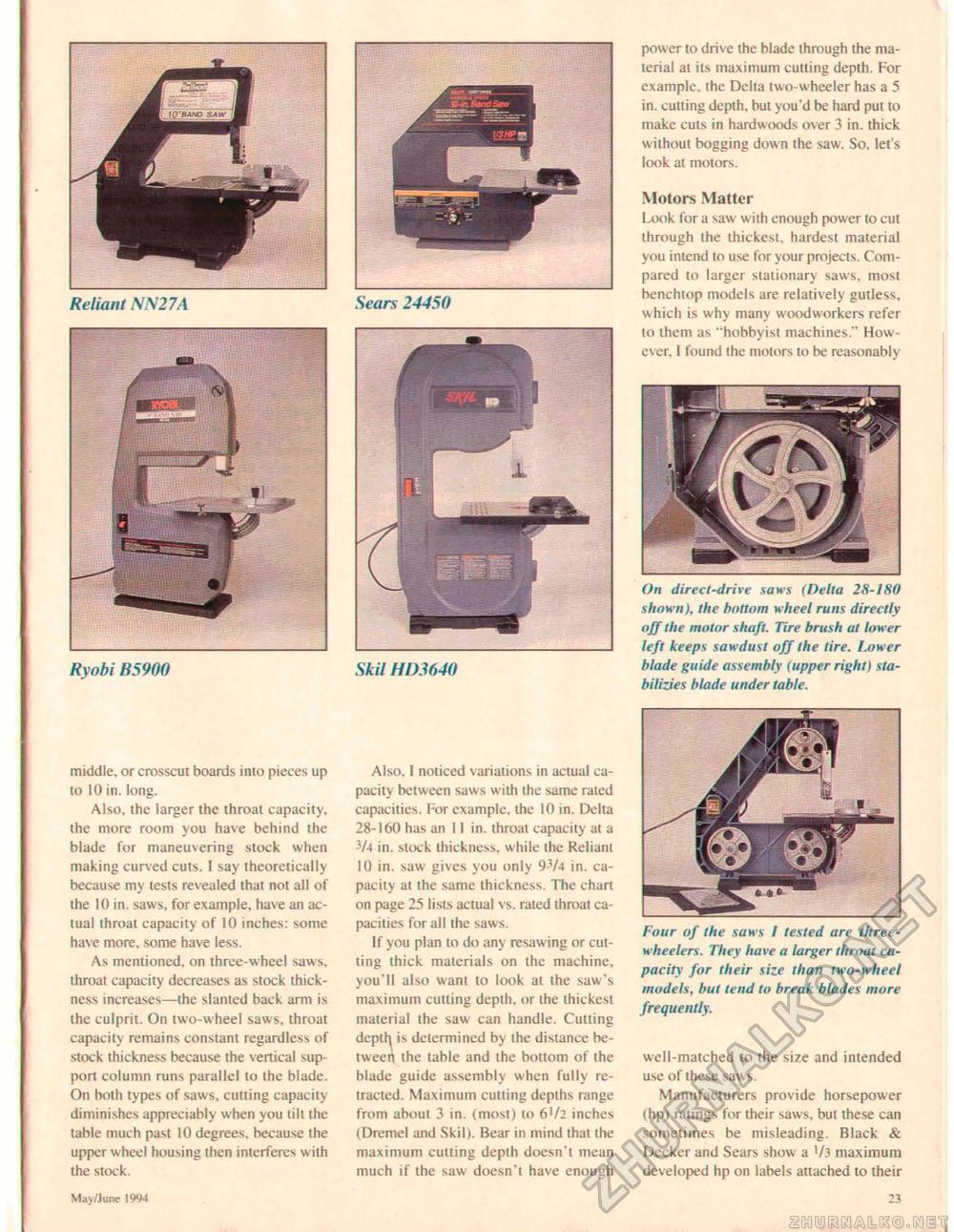

Reliant NN27A Sears 24450 Ryobi BS900 Skil HD3640 On direct-drive .vans (Delta 28-180 shown), the bottom wheel runs directly off the motor shaft. Tire brush at lower left keeps sawdust off the tire. Lower hlade guide assembly (upper right) stabilises blade under table. power to drive the blade through the material at its maximum cutting depth. For example, the Delta two-wheeler has a 5 in. culling depth, but you'd be hard put to make cuts in hardwoods over 3 in. thick without bogging down the saw. So, let's look at motors. Motors Matter Look tor a saw with enough power to cut through the thickest, hardest material you intend to use for your projects. Compared to larger stationary saws, most benchtop models are relatively gutless, which is why many woodworkers refer to them as "hobbyist machines." However, I found the motors to be reasonably middle, or crosscut boards into pieces up to 10 in. long. Also, the larger the throat capacity, the more room you have behind the blade for maneuvering stock when making curved cuts. I say theoretically because my tests revealed that not all of the 10 in. saws, for example, have an actual throat capacity of 10 inches: some have more, some have less. As mentioned, on three-wheel saws, throat capacity decreases as stock thickness increases—the slanted back arm is the culprit. On two-wheel saws, throat capacity remains constant regardless of stock thickness because the vertical support column runs parallel lo the blade. On both types of saws, cutting capacity diminishes appreciably when you till the table much past 10 degrees, because the upper wheel housing then interferes with the stock. Also, I noticed variations in actual capacity between saws wiih the same rated capacities. l;or example, the 10 in. Delta 28-160 has an 11 in. throat capacity at a 3/4 in. stock thickness, while the Reliant 10 in. saw gives you only 93/4 in. capacity at the same thickness. The chart on page 25 lists actual vs. rated throat capacities for all the saws. If you plan to do any resawing or cutting thick materials on the machine, you'll also want to look at the saw's maximum cutting depth, or Lhe thickest material the saw can handle. Cutting depth) is determined by the distance between the table and the bottom of the hlade guide assembly when fully retracted. Maximum cutting depths range from about 3 in. (most) to 6'/2 inches (Dremel and Skil). Bear in mind that the maximum cutting depth doesn't mean much if the saw doesn't have enough Four of the saws I tested are three-wheelers. They have a larger throat capacity for their size than two-wheel models, but tend lo break blades more frequently. well-matched to the size and intended use of these saws. Manufacturers provide horsepower thp) ratings for their saws, but these can sometimes be misleading. Black & Decker and Sears show a '/3 maximum developed hp on labels attached to their May/June 1994 23 |