Woodworker's Journal 1994-18-3, страница 25

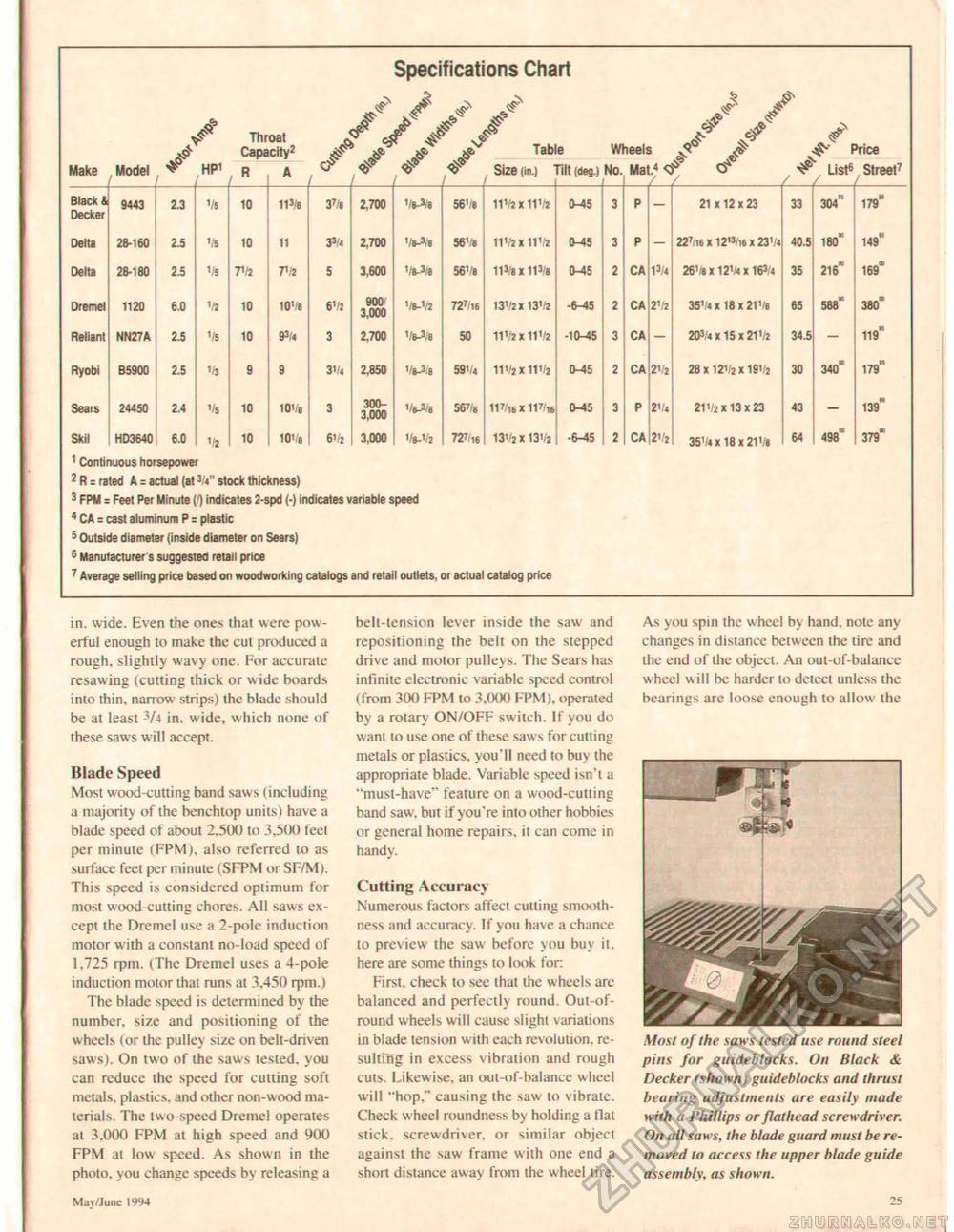

Specifications Chart / Throat / Make Model HP1 r A O* ❖ ❖ ^ Size (in.) Tilt «iq.) No. Mat.' <f J Table Wheels Price Price 21 * 12x23 227|'<6 X 1213/16 X 23V4 261- 8 X 121/4 X 163/4 35V4 x 18 x 2lVa 20"4X 15x211/2 28x121/2x191/2 211/2X13x23 35'>4 x 18 x 21'/e

Black & Decker Delta Delta Dremel Reliant Ryobi Sears Skil 9443 28-160 28-180 1120 NN27A B5900 24450 HD3640 2.3 2.S 2.5 6.0 2.5 2.5 2.4 6.0 Vi 1/5 Vi 1/2 VS 1ft '/S V2 10 10 71/2 10 10 9 10 10 11>/8 11 Vti 10Va 93M 9 10'/e 10Vb 37/8 33/4 5 6V* 3 31/4 3 6V1 2,700 2,700 3,600 900 3.000 2,700 2,850 3003,000 3,000 VbJ/B 'JMft Vt-Vi VtJ/e V»J/B 1/g.Vi 561/« 56V'a 56 Vi 727/I6 50 59V« 56% 727/ie 11'ftrll'ft 11V2 X11V2 m8*n3's 13V2Xl3'/2 111/2x111*2 111/2x111/2 W/isx1V/,s 131/1 x 131/1 0-45 0-45 0-45 -6-45 •10-45 0-45 CMS -6-45 P CA CA CA CA P CA 13/4 21/2 21/4 21/2 21 * 12x23 227|'<6 X 1213/16 X 23V4 261- 8 X 121/4 X 163/4 35V4 x 18 x 2lVa 20"4X 15x211/2 28x121/2x191/2 211/2X13x23 35'>4 x 18 x 21'/e 1 Continuous horsepower 2 R = rated A - actual (at J/4T' stock thickness) 3 FPM = Feet Per Minute (/) indicates 2-spd (-) indicates variable speed 4 CA = cast aluminum P = plastic 5 Outside diameter (inside diameter on Sears) 6 Manufacturer's suggested retail price 7 Average selling price based on woodworking catalogs and retail outlets, or actual catalog price in. wide. Even the ones that were powerful enough to make the cut produced a rough, slightly wavy one. For accurate resawing (cutting thick or wide boards into thin, narrow strips) the blade should be at least -V4 in. wide, which none of these saws will accept. Blade Speed Most wood-cutting band saws (including a majority of the benchtop units) have a blade speed of about 2.500 to 3.500 feet per minute (FPM), also referred to as surface feet per minute (SFPM or SF/M). This speed is considered optimum for most wood-cutting chores. AH saws except the Dremel use a 2-pole induction motor with a constant no-load speed of 1,725 rpm. (The Dremel uses a 4-pole induction motor that runs at 3.450 rpm.) The blade speed is determined by the number, size and positioning of the wheels (or the pulley size on belt-driven saws). On two of the saws tested, you can reduce the speed for cutting soft nietals. plastics, and other non-wood materials. The two-speed Dremel operates at 3.000 FPM at high speed and 900 FPM ai low speed. As shown in the photo, you change speeds by releasing a belt-tension lever inside the saw and repositioning the belt on the stepped drive and motor pulleys. The Sears has infinite electronic variable speed control (from 300 FPM to 3,000 FPM), operated by a rotary ON/OFF switch. If you do want to use one of these saws for cutting metals or plastics, you'll need to buy the appropriate blade. Variable speed isn't a "must-have" feature on a wood-cutting band saw. but if you're into other hobbies or general home repairs, it can come in handy. Cutting Accuracy Numerous factors affect cutting smoothness and accuracy. If you have a chance to preview the saw before you buy it, here are some things to look for First, check to see that the wheels are balanced and perfectly round. Out-ol-round wheels will cause slight variations in blade tension with each revolution, resulting in excess vibration and rough cuts. Likewise, an out-of-balance wheel will "hop." causing the saw to vibrate. Check wheel roundness by holding a flat stick, screwdriver, or similar object against the saw frame with one end a short distance away from the wheel tire. As you spin the wheel by hand, note any changes in distance between the lire and the end of the object. An out-of-balance wheel will be harder to detect unless the bearings are loose enough to allow the Most of the saws tested use round steel pins for guideblocks. On Black & Decker (shown) guideblocks and thrust bearing adjustments are easily made with a Phillips or flathead screwdriver. On all saws, the blade guard must be removed to access the upper blade guide assembly, as shown. May/June 1994 25 |