Woodworker's Journal 1994-18-3, страница 27

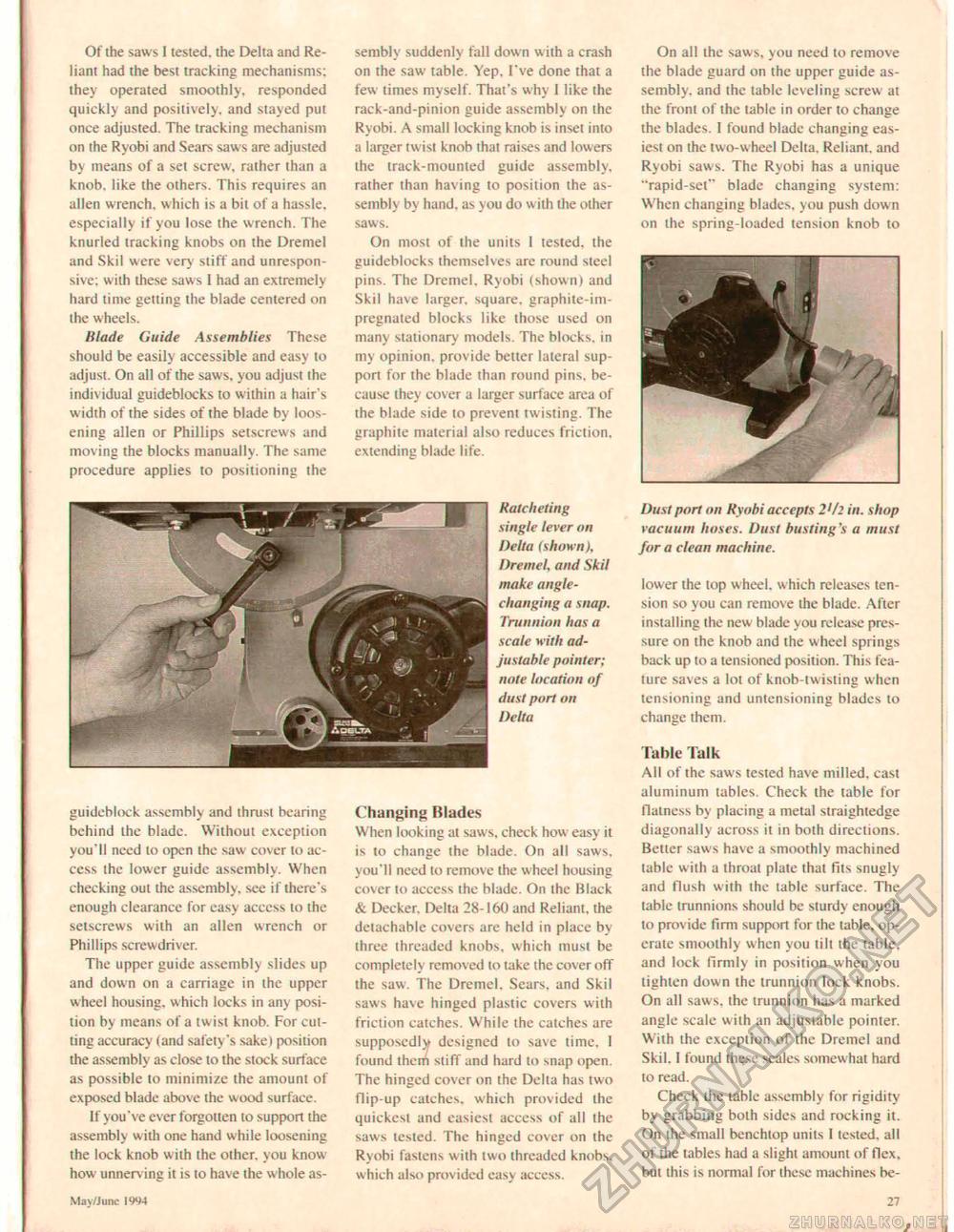

Of the saws I tested, the Delta and Reliant had the best tracking mechanisms: they operated smoothly, responded quickly and positively, and stayed put once adjusted. The tracking mechanism on the Ryobi and Sears saws are adjusted by means of a set screw, rather than a knob, like the others. This requires an alien wrench, which is a bit of a hassle, especially if you lose the wrench. The knurled tracking knobs on the Dremel and Skil were very stiff and unresponsive; with these saws I had an extremely hard time getting the blade centered on the wheels. Hlade Guide Assemblies These should be easily accessible and easy to adjust. On all of the saws, you adjust the individual guideblocks to within a hair s width of the sides of the blade by loosening alien or Phillips setscrews and moving the blocks manually. The same procedure applies to positioning the sembly suddenly fall down with a crash on the saw table. Yep, I've done that a few times myself, That's why I like the rack-and-pinion guide assembly on the Ryobi. A small locking knob is inset into a larger twist knob that raises and lowers the track-mounted guide assembly, rather than having to position the assembly by hand, as you do with the other saws. On most of the units I tested, the guideblocks themselves are round steel pins. The Dremel, Ryobi (shown) and Skil have larger, square, graphile-im-pregnated blocks like those used on many stationary models. The blocks, in my opinion, provide better lateral support for the blade than round pins, because they cover a larger surface area of the blade side to prevent twisting. The graphite material also reduces friction, extending blade life. On all the saws, you need to remove the blade guard on the upper guide assembly. and the table leveling screw at the front of the table in order to change the blades. I found blade changing easiest on the two-wheel Delta, Reliant, and Ryobi saws. The Ryobi has a unique "rapid-set" blade changing system: When changing blades, you push down on the spring-loaded tension knob to Ratcheting single lever on Delta (shown), Dremel, and Skil make angle-changing a snap. Trunnion has a scale with adjustable pointer; note location of dust port on Delta guideblock assembly and thrust bearing behind the blade. Without exception you'll need lo open the saw cover lo access the lower guide assembly. When checking out the assembly, see if there's enough clearance for easy access to the setscrews wilh an alien wrench or Phillips screwdriver. The upper guide assembly slides up and down on a carriage in the upper wheel housing, which locks in any position by means of a twist knob. For culling accuracy (and safety's sake) position the assembly as close to ihe slock surface as possible lo minimize the amount of exposed blade above the wood surface. If you've ever forgotten to support the assembly wilh one hand while loosening the lock knob with the other, you know how unnerving it is to have the whole as- Changing Blades When looking at saws, check how easy it is to change the blade. On all saws, you'll need lo remove ihe wheel housing cover to access the hlade. On the Black & Decker. Delta 28-160 and Reliant, the detachable covers are held in place by three threaded knobs, which must be completely removed lo take the cover off the saw. The Dremel, Sears, and Skil saws have hinged plastic covers with friction catches. While the catches are supposedly designed lo save time. I found them stiff and hard to snap open. The hinged cover on the Delta has two flip-up catches, which provided the quickest and easiest access of all the saws tested. The hinged cover on the Ryobi fastens with two threaded knobs, w hich also provided easy access. Dust port on Ryobi accepts 2th in. shop vacuum hoses. Dust busting's a must for a clean machine. low er the lop w heel, w hich releases tension so you can remove the blade. After installing the new blade you release pressure on the knob and the w heel springs back up to a tensioned position. This feature saves a lot of knob-twisting when tensioning and untensioning blades lo change them. Table Talk All of the saws tested have milled, casl aluminum tables. Check the table for flatness by placing a metal straightedge diagonally across it in both directions. Better saws have a smoothly machined table with a throat plate that fits snugly and flush with the table surface. The table trunnions should be sturdy enough to provide firm support for the lable. operate smoothly when you tilt the table, and lock firmly in position when you tighten down the trunnion lock knobs. On all saws, the trunnion has a marked angle scale with an adjustable pointer. With the exception of the Dremel and Skil. I found ihese scales somewhat hard to read. Check the lable assembly for rigidity by grabbing both sides and rocking it. On ihe small benchtop units I tested, all of the tables had a slight amount of flex, but Ihis is normal for these machines be May/June IW4 27 |