Woodworker's Journal 1994-18-6, страница 14

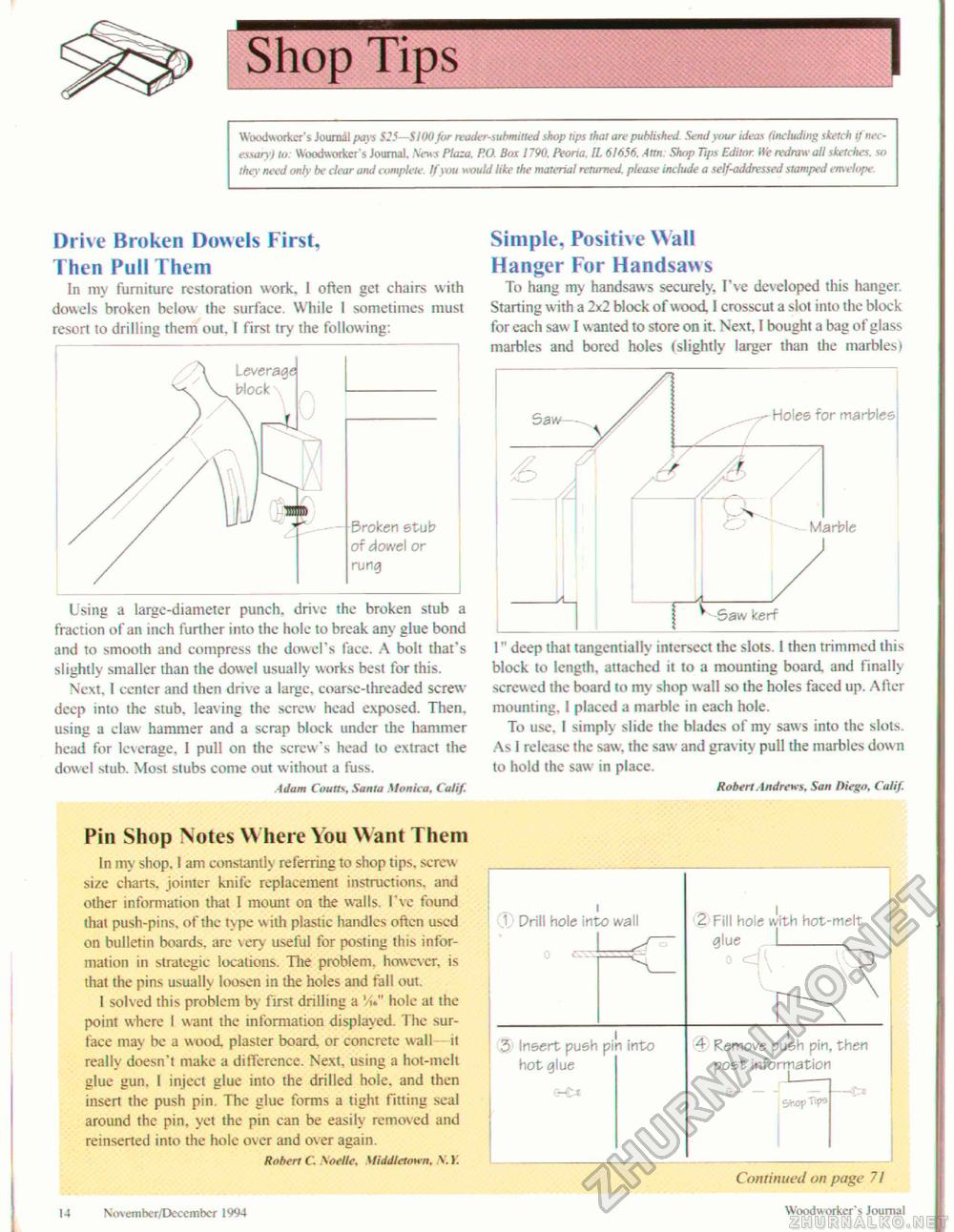

Woodworker's Journal pays $25—S100 for reader-submitted shop tips that are published. Send your ideas (including sketch if necessary) to: Woodworker's Journal. News Plaza. P.O. Box 1790. Peoria. IL 61656, Attn: Shop Tips Editor We redraw all sketches, so the)- need only be clear and complete. If you would like the material returned, please include a self-addressed stamped emvlope. Drive Broken Dowels First, Then Pull Them In my furniture restoration work. 1 often get chairs with dowels broken he low the surface. While I sometimes must resort to drilling them out. I first try the following: Leverage block Broken stub of dowel or rung Using a large-diameter punch, drive the broken stub a fraction of an inch further into the hole to break any glue bond and to smooth and compress the dowel's face. A bolt that's slightly smaller than the dowel usually works best for this. Next, I center and then drive a large, coarse-threaded screw-deep into the stub, leaving the screw head exposed. Then, using a claw hammer and a scrap block under the hammer head for le\erage. I pull on the screw 's head to extract the dowel stub. Most stubs come out without a fuss. Adam Courts, Santa Monica, Calif. Simple, Positive Wall Hanger For Handsaws To hang my handsaws securely. I've developed this hanger. Starting with a 2x2 block of wood, I crosscut a slot into the block for each saw I w anted to store on it. Next. I bought a bag of glass marbles and bored holes (slightly larger than the marbles) 1" deep that tangentially intersect the slots. I then trimmed this block to length, attached it to a mounting board, and finally screw ed the board to my shop wall so the holes faced up. After mounting, I placed a marble in each hole. To use. I simply slide the blades of my saws into the slots. As I release the saw, the saw and gravity pull the marbles down to hold the saw in place. Robert Andrews. San Diego. Calif. 14 Pin Shop Notes Where \bu Want Them In my shop. I am constantly referring to shop tips, screw size charts, jointer knife replacement instructions, and other information that I mount on the walls. I've found that push-pins, of the ty pe w ith plastic handles often used on bulletin boards, are very useful for posting this information in strategic locations. The problem, however, is that the pins usually loosen in the holes and fall out. I solved this problem by first drilling a V hole at the point where I want the information displayed. The surface may be a wood, plaster board or concrete wall it really doesn't make a difference. Next, using a hot-melt glue gun. 1 inject glue into the drilled hole, and then insert the push pin. The glue forms a tight fitting seal around the pin, yet the pin can be easily removed and reinserted into the hole over and over again. Robert C. Soelte. Middletown, V. 11 Novemher/December 1994 1 Drill hole into wall 3 Insert push pin into hot glue 6-<t» 2 Fill hole with hot-melt glue o 4 Remove push pin, then post information 0-- Shop Tips Continued on page 71 Wixxiworkcr's Journal |