Woodworker's Journal 1994-18-6, страница 24

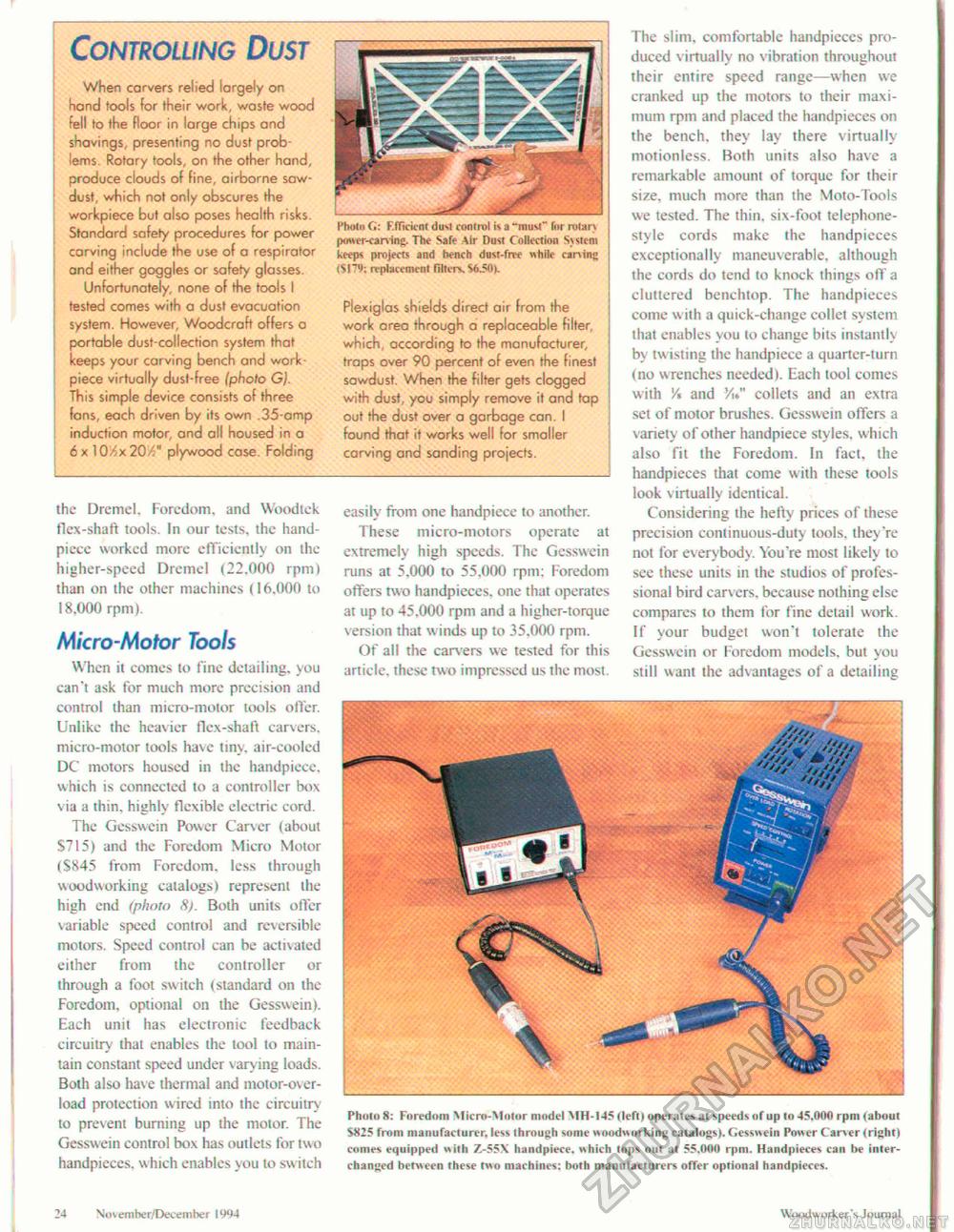

Controlling Dust When carvers relied largely on hand tools for their work, waste wood fell to the floor in large chips and shavings, presenting no dust problems. Rotary tools, on the other hand, produce clouds of fine, airborne sawdust, which not only obscures the workpiece but also poses health risks. Standard safety procedures for power carving include the use of a respirator and either goggles or safety glasses. Unfortunately, none of the tools I tested comes with a dust evacuation system. However, Woodcraft offers a portable dust-collection system that keeps your carving bench and work-piece virtually dust-free /photo C). This simple device consists of three fans, each driven by its own 35-amp induction motor, and all housed in a 6 x 1 0/jx 20/4" plywood cose. Folding the Dremel, Foredom, and Woodtek flex-shaft tools. In our tests, the handpiece worked more efficiently on the higher-speed Dremel <22.000 rprn) than on the other machines (16.000 to 18,000 rpm). Micro-Motor Tools When it comes to fine detailing, you can't ask for much more precision and control than micro-motor tools olTer. Unlike the heavier flex-shaft carvers, micro-motor tools have tiny, air-cooled DC motors housed in the handpiece, which is connected to a controller box via a thin, highly flexible electric cord. The Gesswein Power Carver (about S715) and the Foredom Micro Motor (S845 from Foredom. less through woodworking catalogs) represent the high end (photo 8). Both units offer variable speed control and reversible motors. Speed control can be activated either from the controller or through a foot switch (standard on the Foredom, optional on the Gesswein). Each unit has electronic feedback circuitry that enables the tool to main-lain constant speed under varying loads. Both also hav e thermal and motor-overload protection wired into the circuitry to prevent burning up the motor. The Gesswein control box has outlets for two handpieces, w hieh enables you to switch t'hotn G: Efficient dusi control is si "roust" for rut an power-carving. The Safe Air Dust Collection System keeps projects and bench dust-free while caning (S!T9; replacement filters. S6-50). Plexiglas shields direct air from the work area through a replaceable filter, which, according to the manufacturer, traps over 90 percent of even the finest sawdust. When the filter gets clogged with dusf, you simply remove it and tap out the dust over a garbage can. I found that it works well for smaller carving and sanding projects. easily from one handpiece to another. These micro-motors operate at extremely high speeds. The Gesswein runs at 5,000 to 55,000 rpm: Foredom offers two handpieces, one that operates at up to 45.000 rpm and a higher-torque version that winds up to 35,000 rpm. Of all the carvers we tested for this article, these two impressed us the most. The slim, comfortable handpieces produced virtually no vibration throughout their entire speed range—when we cranked up the motors to their maximum rpm and placed the handpieces on the bench, they lay there virtually motionless. Both units also have a remarkable amount of torque for their size, much more than the Moto-Tools we tested. The thin, six-foot telephone-style cords make the handpieces exceptionally maneuverable. although the cords do tend to knock things off a cluttered benchtop. The handpieces come with a quick-change collet system that enables you to change bits instantly by twisting the handpiece a quarter-turn (no wrenches needed). Each tool comes with V* and V\«." collets and an extra set of motor brushes. Gesswein offers a variety of other handpiece styles, which also fit the Foredom. In fact, the handpieces that come with these tools look virtually identical. Considering the hefty prices of these precision continuous-duty tools, they're not for everybody. You're most likely to see these units in the studios of professional bird carv ers. because nothing else compares to them for fine detail work. If your budget won't tolerate the Gesswein or Foredom models, but you still want the advantages of a detailing Photo 8: Foredom Micro-Motor model MH-I45 (left ) operates at speeds of up to 45.000 rpm (about S825 from manufacturer, less through some woodworking catalogs). Gesswein Power Carver (right) comes equipped with Z-55X handpiece, which tops out at 55,000 rpm. Handpieces can be interchanged between these two machines: both manufacturers offer optional handpieces. 24 November/December 1994 Woodw orker's Journal I |