Woodworker's Journal 2001-25-2, страница 39

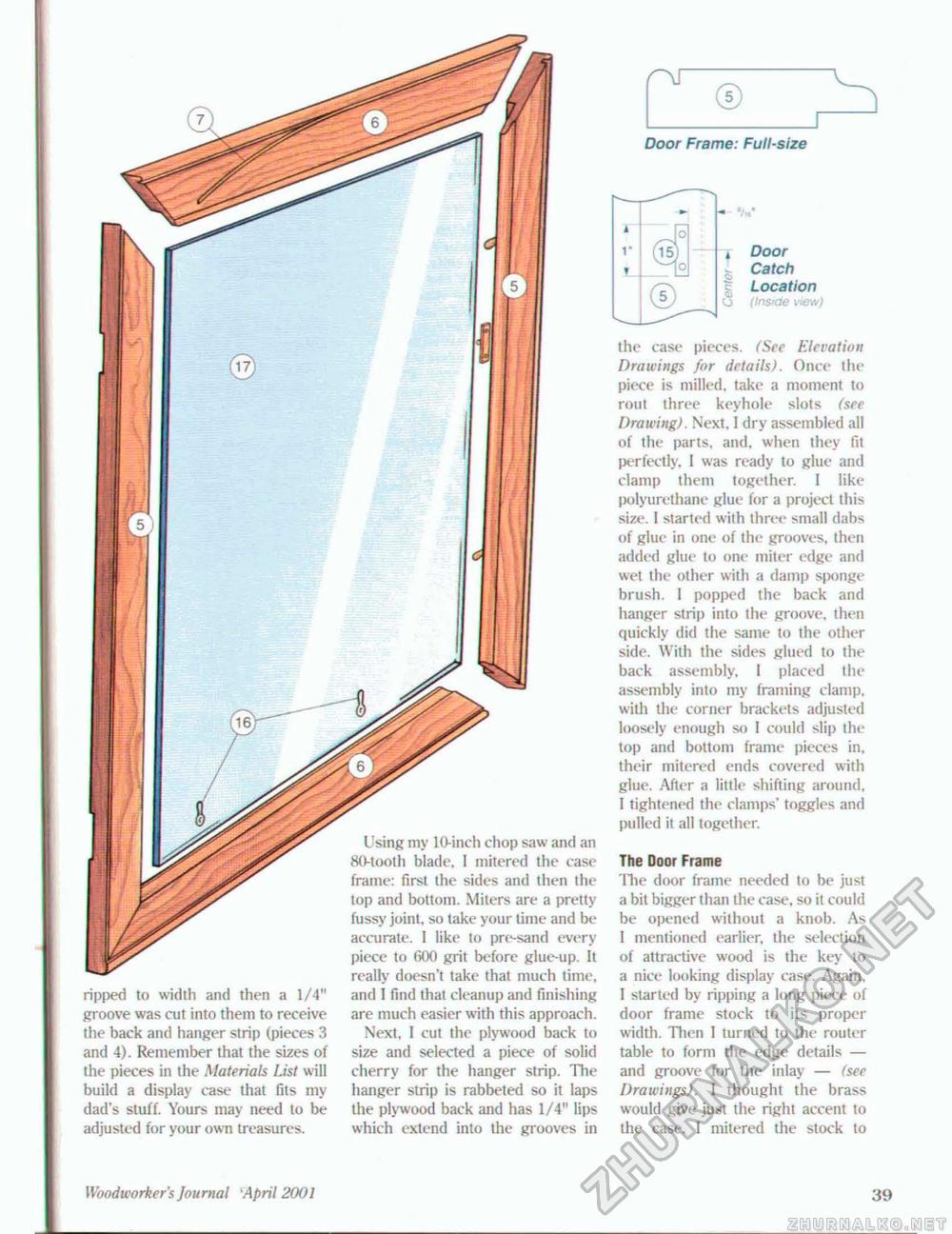

r\r ripped to width and then a 1/4" groove was cut into them to receive the back and hanger strip (pieces 3 and 4). Remember that the sizes of the pieces in the Materials List will build a display case that fits my dad's stuff. Yours may need to be adjusted for your own treasures. © Door Frame: Full-size , Door Catch | Location (Inside view) Using my 10-inch chop saw and an 80-tooth blade, I mitered the case frame: first the sides and then the top and bottom. Miters are a pretty fussy joint, so lake your time and be accurate. I like to pre-sand every piece to 600 grit before glue-up. It really doesn't take that much time, and I find that cleanup and finishing are much easier with this approach. Next, 1 cut the plywood back to size and selected a piece of solid cherry for the hanger strip. The hanger strip is rabbeted so it laps the plywood back and has 1/4" lips which extend into the grooves in the case pieces. (See Elevation Drawings for details). Once the piece is milled, take a moment to rout three keyhole slots (see Drawing). Next, I dry assembled all of the parts, and. when they fit perfectly, I was ready to glue and clamp them together. 1 like polyurethane glue for a project this size. I started with three small dabs of glue in one of the grooves, then added glue to one miter edge and wet the other with a damp sponge brush. 1 popped the back and hanger strip into the groove, then quickly did the same to the other side. With the sides glued to the back assembly, I placed the assembly into my framing clamp, with the corner brackets adjusted loosely enough so I could slip ihe lop and bottom frame pieces in. their mitered ends covered with glue. After a little shifting around, I tightened the clamps' toggles and pulled it all together. The Door Frame lhe door frame needed to be just a bit bigger than the case, so it could be opened without a knob. As I mentioned earlier, the selection of attractive wood is the key to a nice looking display case. Again. 1 started by ripping a long piece of door frame stock to its proper width. Then I turned to the router table to form the edge details — and groove for the inlay — (see Drawings). 1 thought the brass would give just the right accent to the case. I mitered the stock to Woodworker 's Journal April 2001 39 |